Exploring the Efficiency and Versatility of Two-Needle Industrial Sewing Machines for Modern Manufacturing

The Versatility of Two-Needle Industrial Sewing Machines

In the realm of industrial sewing, the efficiency and precision of fabric creation are paramount. Among the diverse array of machines available, the two-needle industrial sewing machine stands out as a vital tool for manufacturers across various sectors. This machine is designed to enhance productivity and provide superior seam quality, making it an indispensable asset in textile production.

What is a Two-Needle Industrial Sewing Machine?

A two-needle industrial sewing machine is equipped with two needles that operate simultaneously, allowing the user to create two parallel rows of stitching. This design is especially beneficial for sewing thicker materials, such as denim or canvas, where strength and durability are critical. The dual-needle configuration not only increases the speed of production but also enables more complex stitching patterns that would be challenging to achieve with a single needle.

Advantages of Using Two-Needle Machines

1. Efficiency and Speed One of the most significant advantages of two-needle sewing machines is their ability to sew faster than single-needle machines. By using two needles simultaneously, operators can double their output without compromising on quality. In a fast-paced industrial environment, this efficiency translates into higher productivity levels and better turnaround times for garments and products.

2. Versatility in Stitching Two-needle industrial sewing machines offer versatile stitching options, catering to a variety of sewing needs. This machine is ideal for creating decorative topstitching, as it can produce a professional finish on products such as jeans, jackets, and bags. Additionally, it can handle elastic materials effectively, making it useful in the production of activewear and swimwear.

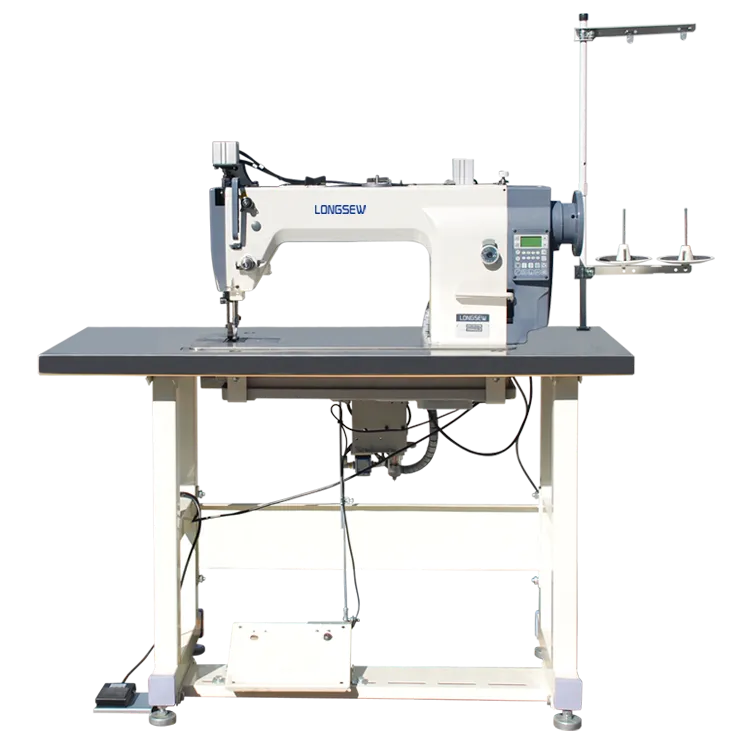

two needle industrial sewing machine

3. Enhanced Strength The two-needle configuration results in a more robust seam, which is essential for items subjected to stress and strain, such as sports apparel and workwear. The dual rows of stitching provide extra reinforcement, ensuring that seams can withstand heavy use without tearing or fraying.

4. Improved Precision With its ability to sew two lines of stitching simultaneously, the two-needle sewing machine enables precise alignment and consistency in stitching. This feature is particularly beneficial for mass production, where uniformity is crucial. Consistent stitch placement reduces rework and waste, contributing to a more efficient manufacturing process.

Applications in the Industry

Two-needle industrial sewing machines are employed across various sectors, including fashion, automotive, and upholstery industries. In apparel manufacturing, they are commonly used for sewing denim products, jackets, and heavier fabrics. In the automotive industry, these machines are vital for creating high-quality seat covers and interiors, while in upholstery, they are used to craft durable furniture coverings and soft furnishings.

Conclusion

The two-needle industrial sewing machine exemplifies the balance between technological innovation and practical application in the textile industry. Its efficiency, versatility, and strength make it a powerhouse for manufacturers seeking to enhance their production capabilities. As the demand for high-quality, durable products continues to rise, these machines will undoubtedly play a crucial role in shaping the future of industrial sewing. Investing in a two-needle sewing machine can provide businesses with a competitive edge, ensuring they meet consumer demands while maintaining high standards of quality and craftsmanship. Whether for small-scale operations or large manufacturing plants, the two-needle industrial sewing machine is a worthy addition to any sewing toolkit.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025