Exploring the Benefits of Spout Mouth Design in Jumbo Bags for Efficient Packing Solutions

The Importance of Jumbo Bag Spout Mouth Sew for Efficient Packaging

In today's fast-paced industrial environment, the efficiency and safety of packaging solutions are paramount. Among the various types of packaging used across industries, jumbo bags—also known as FIBCs (Flexible Intermediate Bulk Containers)—have gained immense popularity for their ability to hold large quantities of products. A significant aspect of these jumbo bags is their spout mouth design, which facilitates easy filling, transportation, and discharge of bulk materials.

What is a Jumbo Bag?

Jumbo bags are large, durable bags made from woven fabric, typically polypropylene. They are designed to carry substantial loads, often ranging from 500 kg to 2000 kg. These bags are highly versatile and can be used for various applications, including the storage and transportation of grains, powders, chemicals, and other bulk materials. One of the key innovations that have enhanced the functionality of jumbo bags is the spout mouth.

The Spout Mouth Design

The spout mouth is a specialized opening at either the top or bottom of the bag designed for efficient loading and unloading. This strategic design element offers several advantages

1. Ease of Use The spout enables quick and precise filling of the bag. Operators can easily insert a hose or conveyor system into the spout for rapid filling, minimizing the time and effort required compared to traditional bags.

2. Controlled Dispensing During the unloading process, the spout mouth allows for controlled dispensing of materials. This is particularly beneficial when dealing with powders or granules that require careful handling to avoid spillage or contamination. The spout helps direct the flow of the material, ensuring an orderly discharge.

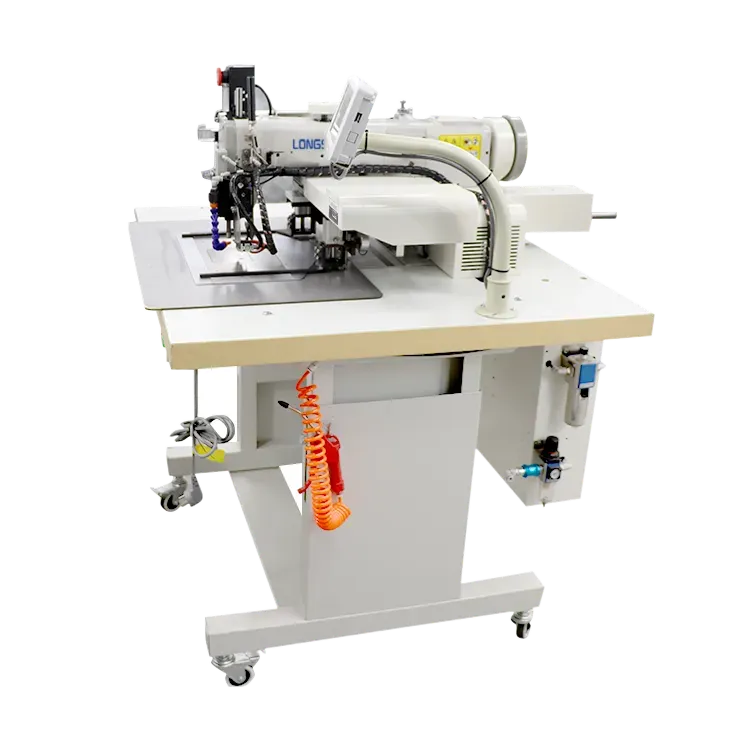

jumbo bag spout mouth sew

3. Reduced Dust and Waste The enclosed nature of the spout reduces dust emissions, which is crucial in industries where cleanliness and safety are concerns. By minimizing dust generation, companies can maintain a healthier work environment and reduce material loss, leading to greater cost savings.

Applications Across Industries

Jumbo bags with spout mouths are widely used in various sectors, including agriculture, construction, pharmaceuticals, and chemicals. In agriculture, for instance, these bags are ideal for storing and transporting feed, fertilizers, and seeds. Their ability to hold large volumes while providing easy access makes them indispensable in warehouse and distribution centers.

In the construction industry, jumbo bags are used to transport sand, gravel, and other aggregates. The spout design facilitates efficient loading and unloading at construction sites, where time is often of the essence. Similarly, in the pharmaceutical sector, controlled dispensing through spout mouths is essential for handling sensitive powders that need to maintain high levels of purity.

Customization Options

Manufacturers often provide customization options for jumbo bags with spout mouths. Companies can choose the size, shape, and material of the bag according to their specific needs. Additionally, printing options for branding or product information can also be incorporated, enhancing the marketing potential of the product while still maintaining functionality.

Conclusion

The spout mouth design of jumbo bags has revolutionized the way bulk materials are handled across various industries. By facilitating easy filling, controlled dispensing, and minimizing dust and waste, these bags have become an essential tool for businesses looking to optimize their packaging processes. As industries continue to evolve and demand more efficient solutions, the jumbo bag with a spout mouth will undoubtedly play a pivotal role in meeting these challenges, ensuring safety, efficiency, and sustainability in packaging practices.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025