Exploring the Benefits and Uses of Double Needle Sewing Machines for Advanced Stitching Techniques

The Versatility of Double Needle Machines in Textile Production

In the world of textile manufacturing, efficiency and precision are paramount. One of the key tools that has revolutionized the industry is the double needle machine. This specialized sewing machine plays a critical role in the production of a wide variety of garments, ensuring not only speed but also the high-quality stitching required for modern apparel.

A double needle machine operates using two needles instead of the standard one. This design allows for two parallel rows of stitching, which provides a number of benefits that single needle machines cannot match. The most obvious advantage is the aesthetic appeal; the double rows of stitching create a clean, professional finish that enhances the overall appearance of the garment. Such characteristics are particularly important in industries where presentation is key, such as fashion and high-end retail.

Another significant benefit of double needle machines is their efficiency. By allowing manufacturers to complete two seams in a single pass, these machines save time and labor costs. In the fast-paced world of textile production, where deadlines are often tight and profit margins slim, the ability to produce garments quickly while maintaining quality is invaluable. This efficiency also translates to increased output, enabling factories to meet high demand without sacrificing craftsmanship.

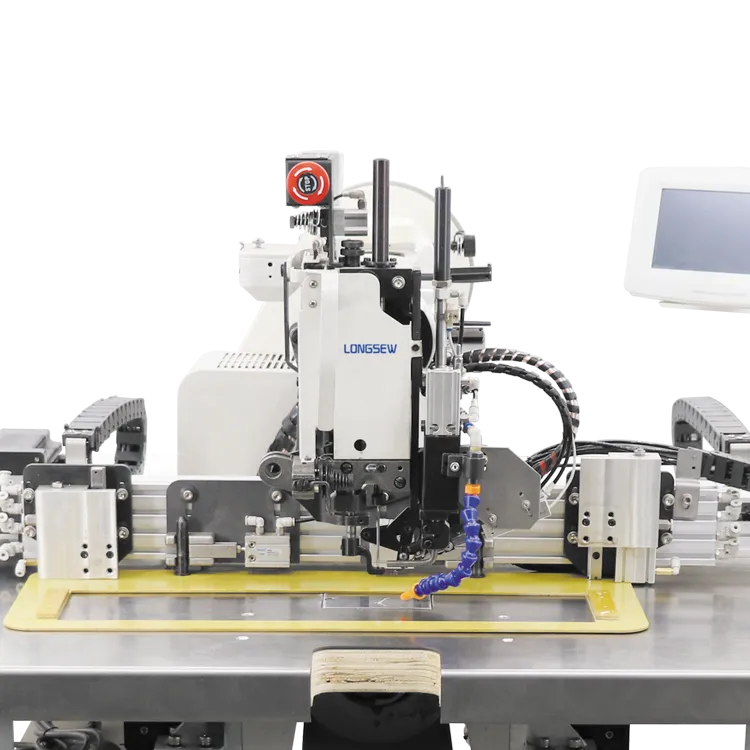

double needle machine

Double needle machines are especially useful for sewing stretch fabrics, such as knits and other elastic materials. The dual stitching technique prevents the seams from puckering or breaking, which is a common issue when working with stretchy materials. This is particularly important for activewear and athleisure garments, which require both a flexible fit and durability to withstand the rigors of physical activity. The reliability of double needle stitching ensures that these garments can maintain their shape and integrity, enhancing customer satisfaction.

Moreover, double needle machines can be equipped with various attachments and features that enhance their functionality. For instance, differential feed options allow for the adjustment of fabric movement, catering to different types of materials. Additionally, various needle sizes and types can be used to accommodate different fabric weights and textures, giving manufacturers the versatility needed to produce a wide range of products.

As sustainability becomes a central focus in the textile industry, double needle machines also offer advantages in terms of material efficiency. Precise stitching minimizes fabric waste, an essential consideration for companies aiming to reduce their ecological footprint. Furthermore, the durability of the seams produced by double needle machines means that garments tend to last longer, which is increasingly important to consumers who are seeking more sustainable and long-lasting fashion options.

In summary, double needle machines are a vital component of modern textile production. Their ability to produce high-quality, aesthetically pleasing seams, coupled with the efficiency they bring to the manufacturing process, makes them indispensable in a competitive industry. As the market evolves and the demand for diverse, durable, and sustainable clothing continues to grow, the double needle machine will undoubtedly remain a key player, empowering manufacturers to meet consumer needs while upholding the standards that define quality apparel. The evolution of this technology will continue to shape the future of textile manufacturing, driving innovation and creativity in fabric construction and design.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025