Exploring the Benefits and Features of Double Coverstitch Sewing Machines for Professional Creations

Understanding the Double Coverstitch Machine A Versatile Tool for Seamstresses

In the world of sewing and garment construction, the double coverstitch machine stands out as a vital tool for creating professional-quality seams. Ideal for knit fabrics, this type of sewing machine provides both functionality and versatility, making it a staple in both home sewing and industrial settings.

What is a Double Coverstitch Machine?

A double coverstitch machine is a specialized sewing machine that forms two rows of stitches on the top side of the fabric while creating a serged or overlocked edge on the underside. This unique capability allows it to produce highly elastic seams, which are essential for knitwear and stretchy fabrics. The double coverstitch is particularly popular for hems, cuffs, and necklines in garments such as t-shirts, leggings, and activewear.

One of the primary features that distinguishes the double coverstitch machine from a regular sewing machine is its ability to handle multiple threads. Typically, it uses four threads—two for the top cover and two for the bottom—resulting in a robust and flexible seam that withstands the stresses of wear and movement. This multi-thread construction is what enables the machine to produce a professional-looking finish that maintains the fabric’s stretch.

Advantages of Using a Double Coverstitch Machine

The advantages of utilizing a double coverstitch machine are numerous. Firstly, the elasticity of the seams allows for a greater range of movement in garments, making them ideal for activewear and other fitted clothing. Unlike standard straight stitches that can break easily under tension, the double coverstitch provides both strength and flexibility.

Additionally, this machine offers a neat and clean finish. Since the underside stitches are covered by the serged edge, there are no raw edges exposed, preventing fraying and ensuring durability. This is particularly important in garments that will be laundered frequently.

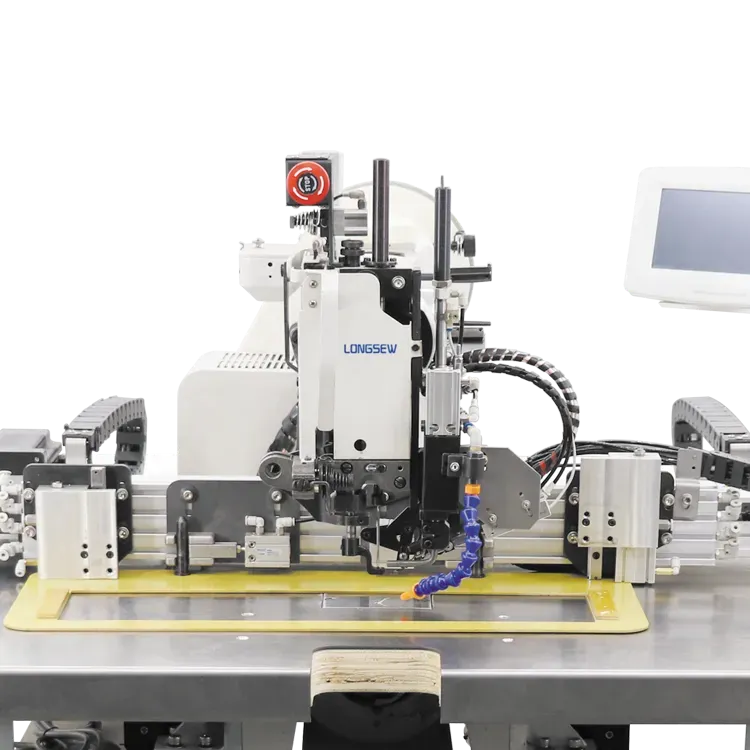

double coverstitch machine

Another key benefit is the ease of operation. Many double coverstitch machines come equipped with adjustable settings for stitch length and tension, allowing users to customize their sewing experience based on the type of fabric and project requirements. Moreover, the use of a double coverstitch machine can save time—hemming and finishing seams can be achieved in one simple pass, unlike traditional methods that may require multiple steps.

Tips for Using a Double Coverstitch Machine

To maximize the performance of a double coverstitch machine, there are some essential tips to keep in mind. Firstly, always use the correct type of needle and thread that is suitable for knit fabrics to achieve optimal results. Ballpoint needles are often recommended for knits as they prevent snagging.

Additionally, it is crucial to practice proper fabric handling to avoid puckering or uneven seams. Stretching the fabric too much while sewing can lead to distortion, so ensure to guide the fabric gently through the machine.

Regular maintenance is also important. Clean the machine to remove lint and debris, and check the tension settings regularly to maintain the quality of stitches.

Conclusion

The double coverstitch machine is an indispensable tool for those who wish to create high-quality, professional-looking garments, particularly when working with knit fabrics. Its unique ability to produce elastic seams, combined with its user-friendly design, makes it a favorite among both hobbyists and professional seamstresses. As sewing continues to evolve, mastering the use of the double coverstitch machine will undoubtedly open up new possibilities for creativity and garment construction. Whether you’re making everyday wear or intricate designs, this machine is sure to enhance your sewing experience.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025