Exploring the Benefits and Applications of Heavy Tailoring Machines in Modern Fabric Production Technology

Heavy Tailoring Machines The Backbone of Precision Craftsmanship

In the realm of fashion and garment production, heavy tailoring machines play a pivotal role in ensuring that every piece of clothing is crafted with the utmost precision and quality. These machines, designed for durability and capability, are crucial for a variety of applications, from bespoke tailoring to large-scale manufacturing. The intricate mechanisms of heavy tailoring machines transform fabric into finished garments, catering to both commercial and individual needs.

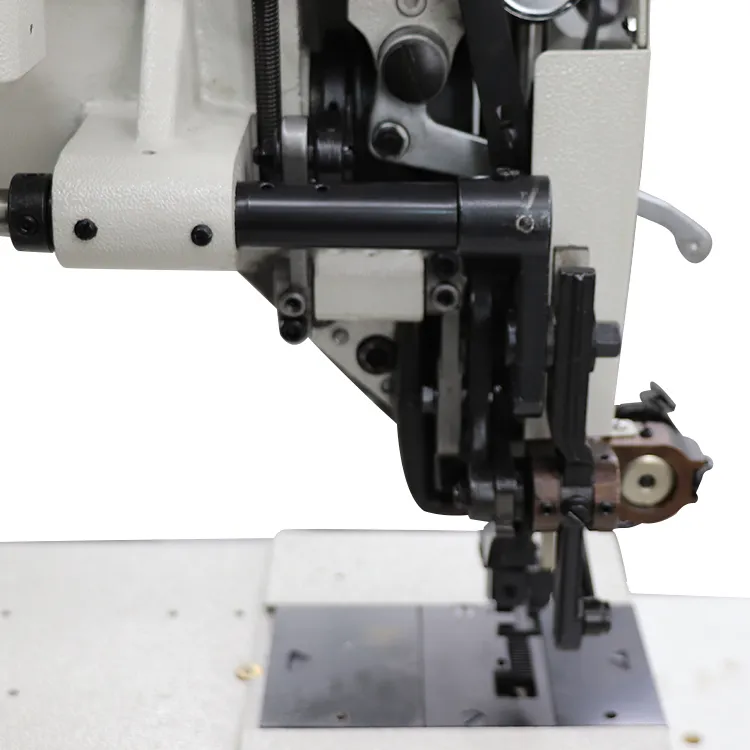

Heavy tailoring machines are engineered to handle thick fabrics and multiple layers, making them essential for creating high-quality garments that require sturdy construction. Unlike standard sewing machines, heavy tailoring machines are built to withstand the rigors of heavy-duty sewing tasks, such as those encountered in upholstery, leatherwork, and the production of workwear. This robustness ensures that the stitching remains consistent and strong, which is particularly important for garments subjected to frequent wear and tear.

One of the standout features of heavy tailoring machines is their ability to offer various stitching options

. These machines often come equipped with specialized foot attachments and sewing capabilities that allow for intricate designs and variable stitch types. This flexibility supports tailors and garment workers in executing complex sewing tasks, such as creating pockets, zippers, and other detailed elements that require expertise and precision.heavy tailoring machine

The operational efficiency of heavy tailoring machines is another significant advantage. Many models are designed with speed settings that cater to both slow, meticulous tasks and high-paced production scenarios. As a result, tailors can adjust their workflow according to the complexity of the project at hand. This adaptability not only boosts productivity but also enhances the overall quality of the finished product.

Furthermore, advancements in technology have led to the evolution of heavy tailoring machines into more sophisticated tools. Modern machines may include computerized systems that allow for automated stitching patterns and precision piecing, thus minimizing the potential for human error. With features like programmable settings and advanced tension controls, these machines can replicate complex designs consistently, which is vital for large production runs or when creating matching garments.

Training and skill development are essential for operators of heavy tailoring machines. While these machines can significantly enhance productivity, a skilled operator harnesses their full potential. Proper training ensures that users understand how to maintain and troubleshoot their machines, leading to extended service life and optimal functionality. Experienced operators can also exploit the capabilities of heavy tailoring machines to push the boundaries of creativity, developing unique designs and styles that set their work apart in a competitive market.

In conclusion, heavy tailoring machines are not merely tools but essential partners in the art of garment making. Their durability, versatility, and technological advancements empower tailors, enabling them to create high-quality clothing that meets the demands of today's consumers. As the fashion industry continues to evolve, these machines will remain a cornerstone of craftsmanship, bridging the gap between traditional techniques and modern innovation. For anyone serious about becoming proficient in fashion design or garment production, understanding and mastering the use of heavy tailoring machines is undoubtedly a fundamental step towards success.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025