Efficient Sewing Solutions for Bag Closing Machines in Industrial Applications

The Importance of Bag Closing Sewing Machines in Modern Production

In the age of rapid industrialization and globalization, the significance of efficient manufacturing processes cannot be overstated. One of the integral components of the packaging industry is the bag closing sewing machine. These machines play a critical role in ensuring that products are securely packaged, thereby facilitating safe transportation and storage. In this article, we will explore the mechanics, benefits, and applications of bag closing sewing machines in contemporary production settings.

Mechanics of Bag Closing Sewing Machines

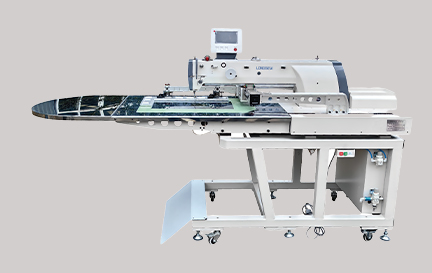

Bag closing sewing machines are specifically designed to secure the open ends of bags made from various materials such as woven polypropylene, jute, cotton, and paper. The most commonly used sewing method involves the use of a heavy-duty sewing thread that can withstand significant tension. These machines are equipped with different types of needle configurations, allowing them to perform various stitches, including straight, zigzag, and overlock, catering to diverse closure requirements.

Modern bag closing sewing machines are equipped with electronic controls that enhance precision and efficiency. Features such as automatic thread cutting, adjustable stitching speed, and integrated conveyor systems contribute to a streamlined bag closing process. Some advanced models even include sensors that detect bag type and size, adapting the machine's settings accordingly for optimal performance.

Benefits of Using Bag Closing Sewing Machines

The implementation of bag closing sewing machines in production lines offers a multitude of advantages. First and foremost, these machines significantly enhance productivity. Manual bag closing is labor-intensive and time-consuming, often leading to inconsistent closure quality. In contrast, sewing machines can operate at high speeds, effortlessly sealing hundreds of bags per hour, thereby reducing labor costs while increasing output.

bag closing sewing machine

Moreover, the reliability of a well-closed bag cannot be understated. Properly sealed bags prevent contamination, spoilage, and spillage, which is particularly crucial in industries like food production and pharmaceuticals. The airtight and secure closures provided by these machines help maintain product quality and integrity, thereby enhancing customer satisfaction and trust in the brand.

Applications Across Various Industries

Bag closing sewing machines find applications across a wide range of industries. In the agricultural sector, they are used for packaging grains, seeds, fertilizers, and animal feed. The ability to secure heavy and bulky bags makes these machines indispensable in ensuring the products reach customers in pristine condition.

In the food industry, bag closing sewing machines are employed to package flour, sugar, rice, and pet food, among others. The demand for hygienic and tamper-proof packaging has driven the need for reliable bag closing solutions that can deliver consistent results. Furthermore, in construction and chemical industries, these machines are essential for packaging substances like cement, sand, and chemicals in durable bags that can withstand external conditions.

Future Innovations in Bag Closing Technology

As technology continues to advance, the future of bag closing sewing machines looks promising. Innovations such as IoT integration, robotics, and automated quality control systems are on the horizon, aiming to further enhance efficiency and accuracy. For instance, smart machines that can monitor their performance in real-time and predict maintenance needs could minimize downtime and save costs.

In conclusion, bag closing sewing machines are an essential component of modern manufacturing and packaging processes. Their ability to enhance efficiency, ensure product integrity, and accommodate a variety of materials makes them valuable assets in numerous industries. As technology evolves, we can expect to see continued advancements that will further optimize the bag closing process, meeting the growing demands of a dynamic global market.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025