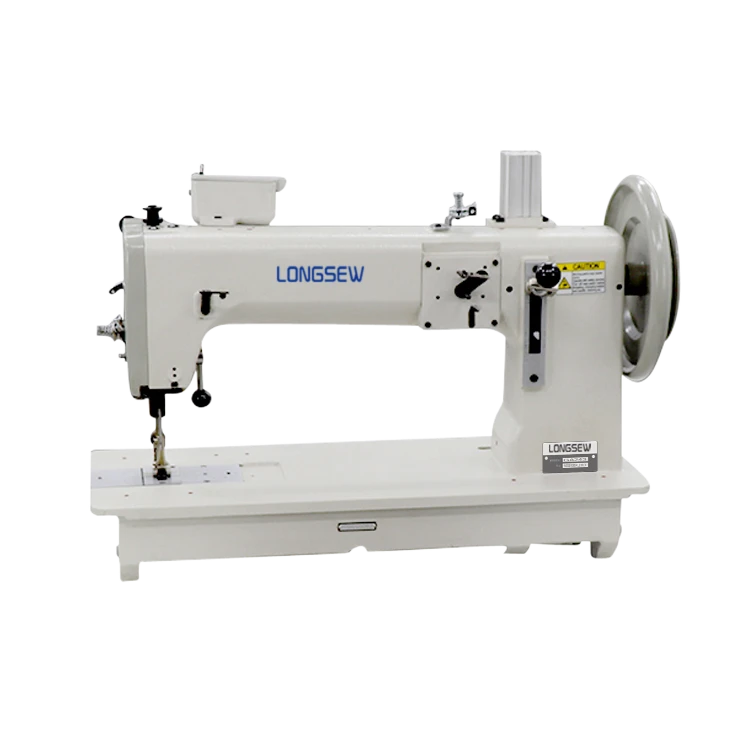

double needle stitching machine

The Significance of Double Needle Stitching Machines in Modern Tailoring

In the ever-evolving world of fashion and garment production, precision, efficiency, and versatility are paramount. One of the tools that significantly enhances these attributes in the tailoring process is the double needle stitching machine. This specialized sewing equipment plays a crucial role in creating high-quality seams that are both aesthetically pleasing and durable.

The double needle stitching machine, as the name suggests, utilizes two needles simultaneously, allowing for the sewing of two parallel lines of stitches. This feature is particularly beneficial in various applications, from creating hems and seams to adding decorative elements to garments. With its ability to produce consistent and uniform stitches, the machine is a favorite among professional tailors and manufacturers alike.

One of the primary advantages of using a double needle stitching machine is the enhanced strength it provides to seams. The dual stitching technique significantly increases the seam's resilience, making it ideal for areas that experience frequent stress, such as armholes, side seams, and waistband areas. This durability not only improves the longevity of garments but also ensures comfort for the wearer, as seams are less likely to rip or fray.

Moreover, the double needle stitching machine offers a unique opportunity for creative expression in fashion design. By varying the distance between the two needles, tailors can create different styles and effects, from subtle decorative touches to bold, contrasting stitches. This flexibility allows designers to differentiate their products in a highly competitive market, where unique and eye-catching designs can make all the difference.

double needle stitching machine

In addition to its creative benefits, the machine is also time-efficient. Traditional sewing methods often require additional steps to create parallel stitches, prolonging the sewing process. However, with a double needle stitching machine, tailors can complete these tasks in one seamless operation. This efficiency not only cuts down on production time but also reduces labor costs, making it an attractive investment for businesses looking to optimize their workflow.

Furthermore, the machine is relatively easy to operate, making it accessible for both seasoned professionals and novice tailors. With basic training, operators can quickly learn to adjust settings for different fabric types and stitching patterns, allowing for greater versatility in garment production.

As sustainability becomes an increasingly important consideration in the fashion industry, the double needle stitching machine also contributes to this goal. By producing stronger seams, it reduces the need for repairs and replacement garments, fostering a more sustainable approach to clothing consumption.

In conclusion, the double needle stitching machine is a vital asset in modern tailoring and garment production. Its ability to create durable, aesthetically pleasing seams while improving efficiency and versatility makes it an indispensable tool for tailors and manufacturers. As the fashion industry continues to evolve, embracing tools that enhance quality and sustainability will be essential, and the double needle stitching machine stands out as a leading choice in this endeavor.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025