double needle price

Understanding the Price Dynamics of Double Needle Machines

In the world of textile manufacturing, precision and quality are fundamental attributes that govern success. Amongst the various sewing technologies, the double needle machine has emerged as a critical tool for ensuring that garments are not only stylish but also durable. However, like any other industrial equipment, the pricing of double needle machines is influenced by a plethora of factors ranging from technological advancements to market demand and global trends. In this article, we delve into the intricacies of double needle machine pricing, its importance in the textile industry, and the factors that influence its market value.

The Importance of Double Needle Machines

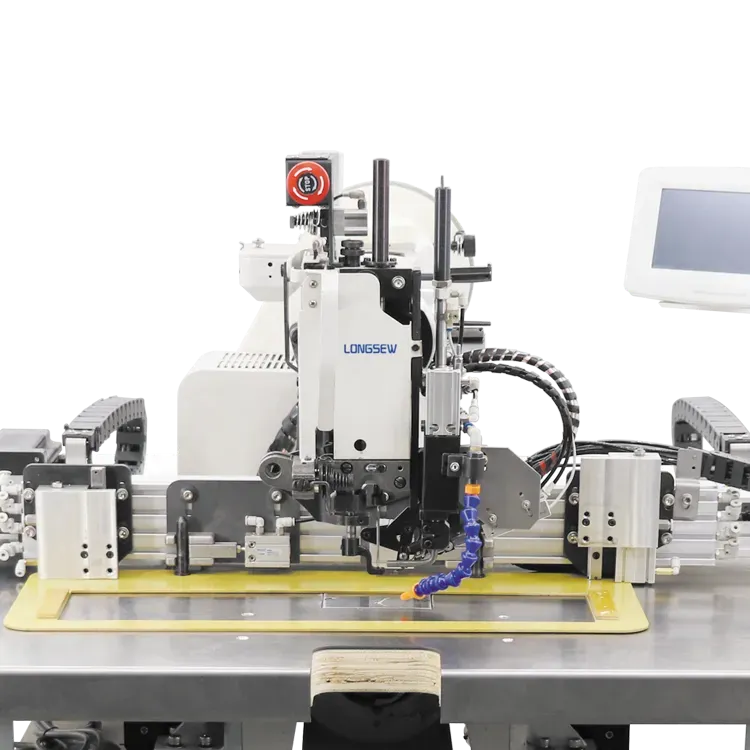

Double needle machines are specialized sewing machines equipped with two needles that can stitch two parallel lines simultaneously. This feature not only enhances the aesthetic appearance of seams but also improves the structural integrity of garments. Commonly used for sewing denim, knitwear, and various other fabrics, these machines are indispensable for manufacturers aiming for high-quality production. The reliability and performance of double needle machines make them a worthy investment for businesses seeking longevity and superior workmanship.

Factors Influencing Double Needle Machine Prices

1. Brand Reputation One of the primary factors that influence pricing is the brand associated with the double needle machine. Renowned brands with a history of quality tooling often command higher prices due to their reliability, service support, and customer trust. Companies like Juki, Brother, and Consew, known for their cutting-edge technology and durability, often position their products at a premium.

2. Specifications and Features The technical specifications of double needle machines, such as stitch types, needle gauge, and additional functionalities (like automatic thread trimming or backstitching), significantly affect their cost. Machines with advanced features, such as programmable settings or integrated digital displays, typically have higher price points due to the technology invested in them.

3. Material and Build Quality The materials used in constructing the machine, including the quality of steel and electronic components, play a vital role in the pricing. Machines made from high-grade materials that promise longevity and minimal wear and tear tend to be more expensive but are often justified by lower maintenance costs in the long run.

double needle price

4. Market Demand and Supply Like other commodities, the prices of double needle machines are subject to fluctuations based on market demand and supply dynamics. During periods of high demand, such as peak production seasons for clothing manufacturers, prices may rise. Conversely, during periods of low demand, prices may stabilize or drop to encourage purchases.

5. Technological Advancements The sewing industry has seen significant technological innovations in recent years, with automation and artificial intelligence playing an increasing role. Machines that incorporate smart technology, enhancing efficiency and reducing labor costs, often attract higher price tags due to their increased productivity potential.

6. Geographical Location The price of double needle machines can also vary significantly across different regions due to shipping costs, tariffs, and local market conditions. Buyers in regions with high import duties may find themselves paying more than their counterparts in countries with lower tariffs on machinery.

The Value Proposition of Investing in Double Needle Machines

While the initial investment in a double needle machine may be substantial, the long-term benefits can far outweigh the upfront costs. Manufacturers experience time savings, enhanced seam quality, and reduced labor costs, ultimately leading to higher profitability. Additionally, the ability to produce intricate designs and patterns can open new market channels for businesses, providing a competitive edge.

Conclusion

Understanding the price dynamics of double needle machines is crucial for textile manufacturers and entrepreneurs looking to invest in their production capabilities. By considering the various factors influencing prices, businesses can make informed decisions that align with their needs and budget constraints. As the industry continues to evolve, staying abreast of the latest trends and advancements will further enable manufacturers to enhance their production processes, ensuring they remain competitive in an ever-changing market landscape.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025