Jan . 13, 2025 17:49

Back to list

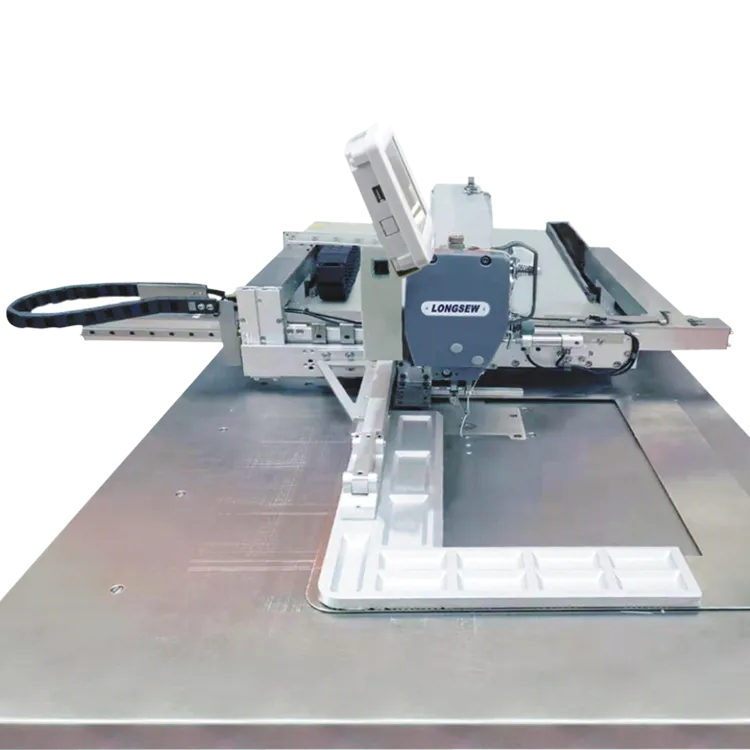

double needle lock stitch sewing machine

The double needle embroidery machine stands out as a transformative tool, offering efficiency, precision, and unparalleled creativity in the world of textile decoration. For businesses and hobbyists alike, the nuances of utilizing this machine can drastically influence production outcomes and the quality of the final product.

In terms of expertise, operating a double needle embroidery machine does require a certain level of skill mastery. Users must be trained to understand thread types, tension settings, and maintenance protocols. This machine is engineered for those who appreciate the nuance in textile art, offering an array of settings that can be adjusted for different materials and designs. As an authoritative source, the Textile Institute has recognized skilled operation of double needle machines as imperative in professional embroidery education and practice. Trustworthiness in a machine comes from its performance and durability. Leading manufacturers have built these machines with industrial-grade components, ensuring longevity and consistent performance under demanding conditions. Warranty offerings and customer service support from reputable brands further solidify their reliability, making them a sound investment for businesses looking to expand their embroidery capabilities. Lastly, real-world experience shared by long-term users reveals the dual advantages of aesthetics and productivity. Many have noted that the enhanced efficiency does not compromise on quality, allowing them to meet large order quotas with ease while still offering customized, highly detailed designs. This user feedback loops back into trust, as prospective buyers can rely on actual performance data and testimonials rather than marketing alone. In summation, the double needle embroidery machine is more than a tool—it's a partner in the craft of creativity and business. Its blend of speed, precision, and reliability makes it indispensable for anyone serious about embroidery, from expert designers to burgeoning businesses. As technology continues to evolve, those who can master and leverage these machines will undoubtedly lead the charge in innovative and efficient textile design.

In terms of expertise, operating a double needle embroidery machine does require a certain level of skill mastery. Users must be trained to understand thread types, tension settings, and maintenance protocols. This machine is engineered for those who appreciate the nuance in textile art, offering an array of settings that can be adjusted for different materials and designs. As an authoritative source, the Textile Institute has recognized skilled operation of double needle machines as imperative in professional embroidery education and practice. Trustworthiness in a machine comes from its performance and durability. Leading manufacturers have built these machines with industrial-grade components, ensuring longevity and consistent performance under demanding conditions. Warranty offerings and customer service support from reputable brands further solidify their reliability, making them a sound investment for businesses looking to expand their embroidery capabilities. Lastly, real-world experience shared by long-term users reveals the dual advantages of aesthetics and productivity. Many have noted that the enhanced efficiency does not compromise on quality, allowing them to meet large order quotas with ease while still offering customized, highly detailed designs. This user feedback loops back into trust, as prospective buyers can rely on actual performance data and testimonials rather than marketing alone. In summation, the double needle embroidery machine is more than a tool—it's a partner in the craft of creativity and business. Its blend of speed, precision, and reliability makes it indispensable for anyone serious about embroidery, from expert designers to burgeoning businesses. As technology continues to evolve, those who can master and leverage these machines will undoubtedly lead the charge in innovative and efficient textile design.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025