Jan . 13, 2025 10:41

Back to list

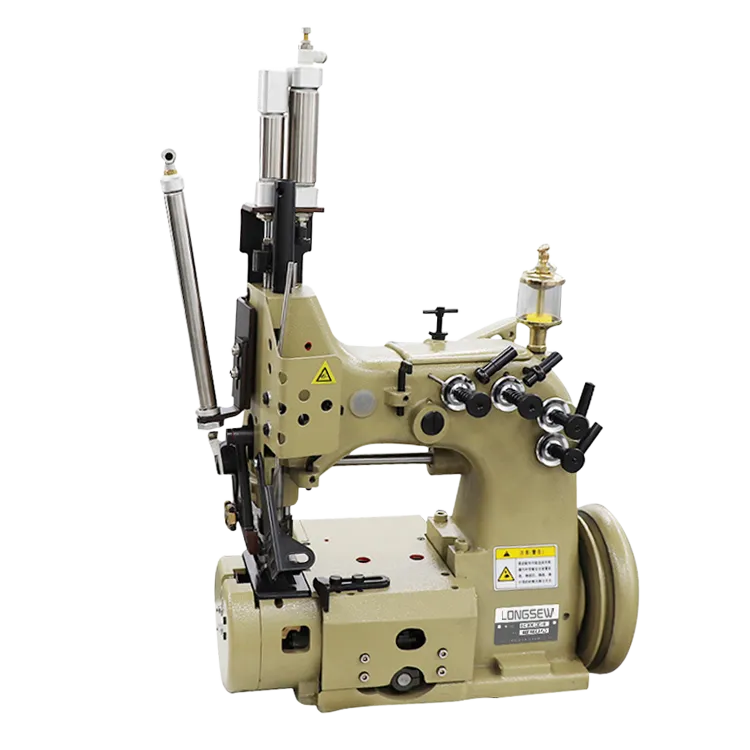

double needle lock stitch sewing machine

For anyone involved in the world of sewing, a two-needle sewing machine is an invaluable asset, bringing professionalism and efficiency to the task. Understanding its detailed intricacies and the advantage it holds over standard single-needle machines is crucial for both veterans and new users in the textile industry.

Training is a critical component to anyone planning to harness the full power of a two-needle sewing machine. Proper instruction can make the difference between a successful project and a frustrating experience. It is essential to learn to adjust needle spacing, tension control, and thread changes effectively. Additionally, regular maintenance and servicing are advised to ensure the machine's longevity and top performance. Authoritativeness in the field of sewing machines comes from an understanding of both their historical and contemporary significance. Historically, the innovation of the two-needle sewing machine marked a transformative period in garment production, taking it from artisanal to industrial. Modern adaptations have incorporated technology to enhance precision and reduce manual error, further cementing their place as a critical tool in textile manufacturing. Trustworthiness in product recommendation is built on firsthand experience and continuous updating of knowledge. Users are encouraged to read reviews, watch demonstrations, and, if possible, visit trade shows or stores to test the machines themselves. It's about understanding precise requirements and aligning them with a machine’s specifications. In conclusion, a two-needle sewing machine is not just a tool—it’s an integral part of crafting garments with efficiency and finesse. Its dual-thread functionality, combined with advances in technology, makes it a worthwhile investment for both individual artisans and large-scale producers. By learning about its operation and maintaining it regularly, users can ensure that it remains an asset for years to come. With informed selection, proper usage, and diligent maintenance, these machines are more than capable of meeting—and exceeding—expectations in quality and output.

Training is a critical component to anyone planning to harness the full power of a two-needle sewing machine. Proper instruction can make the difference between a successful project and a frustrating experience. It is essential to learn to adjust needle spacing, tension control, and thread changes effectively. Additionally, regular maintenance and servicing are advised to ensure the machine's longevity and top performance. Authoritativeness in the field of sewing machines comes from an understanding of both their historical and contemporary significance. Historically, the innovation of the two-needle sewing machine marked a transformative period in garment production, taking it from artisanal to industrial. Modern adaptations have incorporated technology to enhance precision and reduce manual error, further cementing their place as a critical tool in textile manufacturing. Trustworthiness in product recommendation is built on firsthand experience and continuous updating of knowledge. Users are encouraged to read reviews, watch demonstrations, and, if possible, visit trade shows or stores to test the machines themselves. It's about understanding precise requirements and aligning them with a machine’s specifications. In conclusion, a two-needle sewing machine is not just a tool—it’s an integral part of crafting garments with efficiency and finesse. Its dual-thread functionality, combined with advances in technology, makes it a worthwhile investment for both individual artisans and large-scale producers. By learning about its operation and maintaining it regularly, users can ensure that it remains an asset for years to come. With informed selection, proper usage, and diligent maintenance, these machines are more than capable of meeting—and exceeding—expectations in quality and output.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025