Jan . 15, 2025 01:24

Back to list

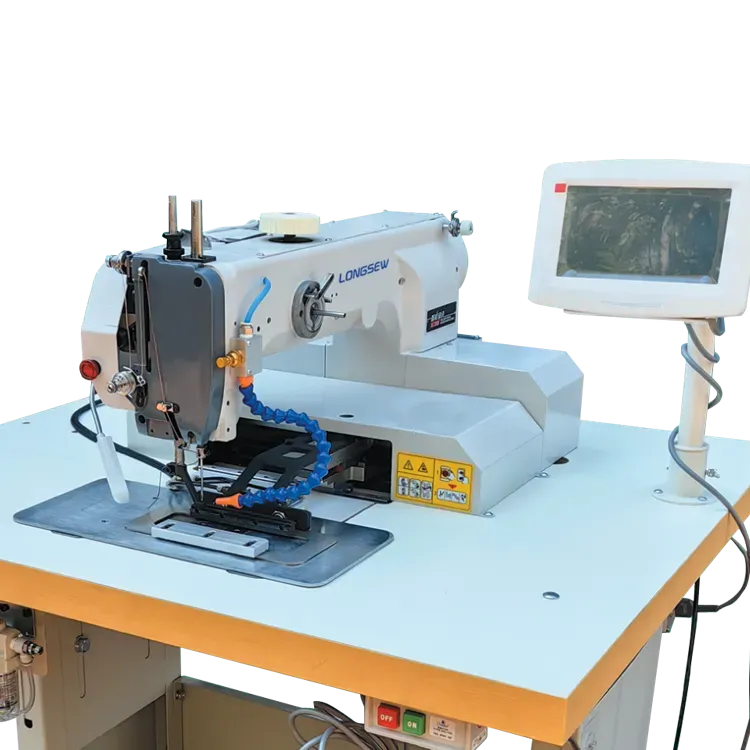

double needle lock stitch machine

Double needle lock stitch machines are essential tools in the world of professional sewing, especially for those seeking to enhance their production capabilities with precision and efficiency. As an authoritative figure in the sewing industry, one can attest to the transformative impact these machines have on both amateur and seasoned sewing enterprises.

From a technical perspective, the expertise required to operate these machines is supported by the widespread availability of specialized training programs and manuals, provided by manufacturers who have established themselves as industry leaders. Brands like Juki, Brother, and Singer are renowned for their durable, user-friendly machines that stand the test of time. Such manufacturers continue to innovate, incorporating technological advancements like computerized controls and automatic thread-cutting functions to enhance their machines’ precision and user-friendliness. The authority of double needle lock stitch machines in the sewing industry cannot be overstated. They serve as the workhorses of garment factories and bespoke tailoring shops alike. The ability to produce uniform, durable stitches across a wide range of fabrics has cemented their position as indispensable tools for serious practitioners. Trustworthiness, a crucial component in the sewing community, is reinforced through consistent performance and reliable outcomes. Users often share positive testimonials and reviews based on their firsthand experiences, validating the machine's efficacy and dependability. When considering an investment in sewing machinery, the validation from long-term users and industry experts alike provides peace of mind for prospective buyers. In conclusion, the double needle lock stitch machine is more than just a sewing tool; it’s a symbol of craftsmanship, efficiency, and innovation. By offering enhanced strength, aesthetic appeal, and production capabilities, it empowers users to deliver top-tier results consistently. As the sewing industry continues to evolve, this machine remains a cornerstone for those aspiring to elevate their craft to new heights.

From a technical perspective, the expertise required to operate these machines is supported by the widespread availability of specialized training programs and manuals, provided by manufacturers who have established themselves as industry leaders. Brands like Juki, Brother, and Singer are renowned for their durable, user-friendly machines that stand the test of time. Such manufacturers continue to innovate, incorporating technological advancements like computerized controls and automatic thread-cutting functions to enhance their machines’ precision and user-friendliness. The authority of double needle lock stitch machines in the sewing industry cannot be overstated. They serve as the workhorses of garment factories and bespoke tailoring shops alike. The ability to produce uniform, durable stitches across a wide range of fabrics has cemented their position as indispensable tools for serious practitioners. Trustworthiness, a crucial component in the sewing community, is reinforced through consistent performance and reliable outcomes. Users often share positive testimonials and reviews based on their firsthand experiences, validating the machine's efficacy and dependability. When considering an investment in sewing machinery, the validation from long-term users and industry experts alike provides peace of mind for prospective buyers. In conclusion, the double needle lock stitch machine is more than just a sewing tool; it’s a symbol of craftsmanship, efficiency, and innovation. By offering enhanced strength, aesthetic appeal, and production capabilities, it empowers users to deliver top-tier results consistently. As the sewing industry continues to evolve, this machine remains a cornerstone for those aspiring to elevate their craft to new heights.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025