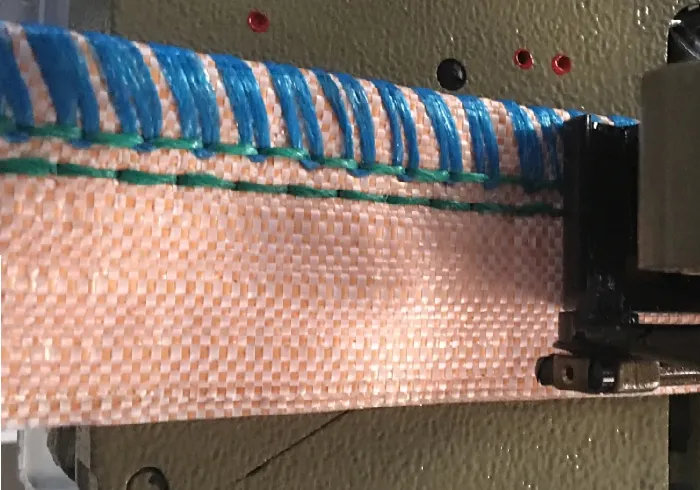

double needle embroidery machine

The Versatility and Advancements of Double Needle Embroidery Machines

In the world of textile and garment manufacturing, the double needle embroidery machine stands out as a pivotal innovation, marrying advanced technology with creative possibilities. This machine has transformed the embroidery landscape, allowing for greater precision, efficiency, and creativity in producing intricate designs on fabric. With the ability to use two needles simultaneously, these machines enable embroiderers to create detailed patterns that were once time-consuming or impossible to achieve with single-needle models.

How It Works

At its core, a double needle embroidery machine operates by using two independent needles, each capable of stitching with different colors of thread. This setup allows for complex designs to be embroidered in a single pass, reducing the time and labor required for manual changes and thread management. Each needle can work with a different bobbin thread, enabling the creation of multi-colored designs without interrupting the embroidery process. This efficiency not only streamlines production but also enhances the quality of the finished product, as there is less room for error when switching threads.

Applications

The versatility of double needle embroidery machines is evident across various sectors. In the fashion industry, they are used to embellish clothing items, creating unique apparel that attracts customers. Sportswear manufacturers employ these machines to add logos and team insignias to uniforms, ensuring durability and vibrancy in their designs. Additionally, home décor businesses utilize double needle embroidery for creating intricate patterns on pillowcases, tablecloths, and other textile products. The education and corporate sectors also benefit from this technology, as embroidered patches and logos serve as important branding tools.

Technological Advancements

double needle embroidery machine

The evolution of double needle embroidery machines reflects broader trends in technology. Modern machines are equipped with digital displays and software that allow operators to design and modify patterns with ease. Users can upload custom designs directly to the machine via USB, enabling a seamless transition from concept to production. Furthermore, advancements in automated technology and robotics have improved the precision and speed of these machines, making them a valuable investment for businesses aiming to keep up with demand.

Benefits Over Single Needle Machines

While single needle embroidery machines remain popular, double needle machines offer distinct advantages. The most notable benefit is their speed; with two needles working simultaneously, the time required to complete an embroidery job is considerably reduced. This efficiency translates to higher productivity rates, enabling businesses to take on larger orders and meet tight deadlines with ease.

Moreover, double needle machines produce more complex stitching patterns that single needle models simply cannot replicate. This capability grants embroiderers the freedom to experiment with unique designs, resulting in distinctive products that stand out in a crowded market. The enhanced visual appeal of double needle embroidery can give brands a competitive edge, making it a strategic choice for businesses looking to differentiate themselves.

Conclusion

As the embroidery industry continues to evolve, double needle embroidery machines are poised to remain at the forefront of innovation. Their blend of efficiency, versatility, and technological advancement makes them a crucial asset for any textile manufacturer or embroiderer. With the ability to produce intricate, high-quality designs quickly, these machines empower businesses to push creative boundaries while meeting the growing demands of consumers.

Investing in a double needle embroidery machine not only improves production efficiency but also elevates the quality of craftsmanship in the embroidery sector. As trends evolve and the appetite for personalized and custom-embroidered products grows, the role of double needle machines will undoubtedly become more prominent, shaping the future of embroidery for years to come.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025