Cost Analysis of Double Needle Chain Stitch Machines for Textile Industry

Understanding the Price of Double Needle Chain Stitch Machines

In the ever-evolving world of textile manufacturing, the pursuit of efficiency, quality, and durability is paramount. Among the equipment that plays a significant role in this industry is the double needle chain stitch machine. This specialized sewing machine has gained popularity for its unique stitching capabilities, allowing manufacturers to create strong seams while utilizing various types of fabrics. However, one of the most pressing questions for businesses looking to purchase such a machine is what is the price of a double needle chain stitch machine?

The Basics of Double Needle Chain Stitch Machines

Before delving into pricing, it is essential to understand what a double needle chain stitch machine is. This machine uses two needles and a single bobbin to create a chain-like stitch, making it suitable for joining layers of fabric, particularly in garments such as denim jeans, where strength and durability are vital. The double needle allows for parallel stitching, which not only enhances the seam's aesthetic but also increases its robustness.

Factors Influencing Price

Several factors can significantly influence the price of double needle chain stitch machines

1. Brand and Manufacturer The reputation of the manufacturer often plays a critical role in the pricing of their machines. Well-established brands with a history of quality usually command higher prices due to their reliability and advanced technology. For instance, brands such as Juki, Brother, and Bernina are known for their high-performance machines that typically come with a higher price tag.

2. Features and Specifications Machines come with various features, such as automatic threading, programmable stitch lengths, and the ability to handle different fabric types. More advanced machines with additional features and specifications will naturally fall on the higher end of the price spectrum.

3. Country of Origin The origin of the machine can also affect its price. Machines manufactured in countries with high labor costs, like Germany or Japan, may be pricier than those produced in countries with lower production costs. However, it's worth noting that a higher price does not always equate to better quality.

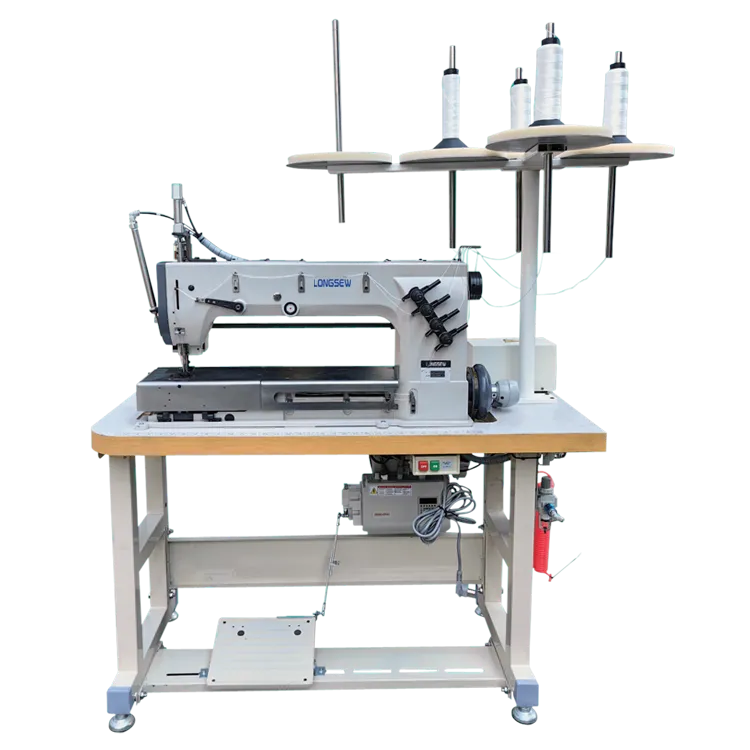

double needle chain stitch machine price

4. New vs. Used Machines The choice between purchasing a new or a used machine can greatly affect the cost. New machines typically have warranties, the latest technology, and higher prices. In contrast, used machines can offer significant savings but may come with risks such as wear and tear or lack of support.

5. Market Demand Economic factors and market demand for specific types of machines can also influence pricing. During periods of high demand, prices may increase due to scarcity or increased production costs.

Typical Price Ranges

On average, the price of a double needle chain stitch machine can vary widely. For basic models designed for small businesses or domestic use, prices can start around $600 to $1,200. Mid-range machines that offer more features and greater durability typically range from $1,200 to $3,000. High-end industrial models, designed for heavy-duty use in manufacturing settings, can cost between $3,000 and $10,000 or more.

Making a Purchase Decision

When considering the purchase of a double needle chain stitch machine, businesses must analyze their specific needs. Assessing production volume, types of fabrics used, and the desired stitch quality will help narrow down the options. Additionally, it is wise to factor in maintenance costs and the availability of replacement parts.

Before finalizing a purchase, conducting thorough research is essential. This could include reading product reviews, consulting with industry peers, and even testing machines in person, if possible. Furthermore, many manufacturers and distributors provide financing options or leasing agreements, which can ease the initial financial burden.

Conclusion

Investing in a double needle chain stitch machine can significantly enhance the quality and durability of textile products. While prices vary widely based on several factors, understanding these elements can help businesses make informed decisions. By carefully evaluating needs, potential manufacturers, and machine specifications, companies can find a machine that offers the best balance of quality and cost, ultimately leading to improved production outcomes and business success.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025