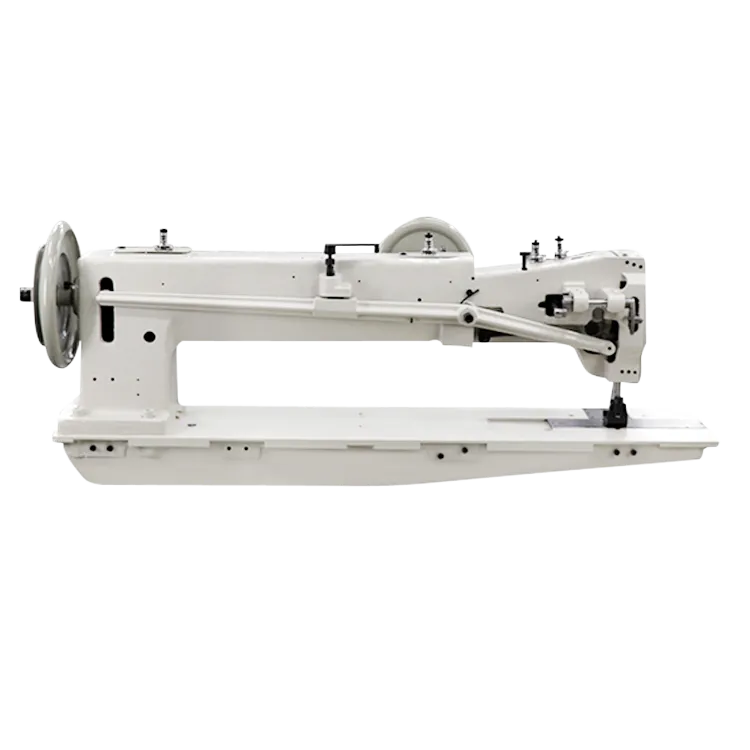

double needle chain stitch machine

Understanding the Double Needle Chain Stitch Machine A Comprehensive Overview

The textile and garment industry has undergone significant transformations over the years, driven primarily by technological advancements that enhance efficiency and quality. One such innovation pivotal to modern sewing is the double needle chain stitch machine. This unique equipment plays a crucial role in producing high-quality seams that are both durable and aesthetically pleasing, making it indispensable for manufacturers aiming to deliver superior products.

What is a Double Needle Chain Stitch Machine?

As the name suggests, a double needle chain stitch machine operates using two needles simultaneously. These needles create a chain stitch, which is a type of stitch characterized by a looped thread that extends from one side of the fabric to the other. This machine allows for two lines of stitching to be created in one pass, enabling greater flexibility in garment construction and finishing.

The primary advantage of double needle chain stitches lies in their unique construction. The stitch forms a series of interlocking loops that provide excellent tensile strength, making it ideal for seams that undergo significant stress and strain. This feature is especially valuable in the production of items such as jeans, jackets, and activewear—garments that require robust construction.

Applications in the Garment Industry

Double needle chain stitch machines are widely used in various applications within the garment industry. For instance, they are commonly employed in the production of

1. Flat Seams The machine excels in creating flat seams, which are crucial for producing a clean finish without bulk. This is particularly important in activewear and swimwear, where comfort and aesthetics are paramount.

2. Decorative Stitching Many manufacturers employ double needle chain stitches for decorative effects. The capability to align two threads simultaneously opens up creative possibilities for embellishing garments with contrasting colors and designs.

3. Binding and Hemming The double needle configuration is effective for binding and hemming operations, providing a neat finish while securing the fabric layers together.

double needle chain stitch machine

4. Knit Fabric Construction The flexibility of the chain stitch makes it well-suited for sewing knit fabrics, which require a stitch that can stretch without breaking.

Advantages of Using a Double Needle Chain Stitch Machine

The double needle chain stitch machine offers several benefits that enhance productivity and product quality. These include

- Increased Efficiency By allowing two lines of stitching in a single operation, the machine significantly reduces production time. This added efficiency can lead to lower labor costs and greater output.

- Improved Durability The chain stitch’s inherent strength makes garments more durable, allowing them to withstand wear and tear without compromising integrity.

- Versatility The ability to use different thread colors and materials enables manufacturers to innovate and produce a wide array of products suited to various markets.

- Cost-Effectiveness With its efficiency and durability, investing in a double needle chain stitch machine can yield long-term savings for manufacturers, making it a wise choice for those looking to enhance their production capabilities.

Conclusion

In summary, the double needle chain stitch machine is a vital tool within the textile and garment industry, characterized by its unique capability to create strong, efficient, and aesthetically pleasing seams. As market demands continue to evolve, this machine's versatility positions it as a frontrunner in garment production technology. Manufacturers adopting this advanced sewing technology benefit from improved efficiency, durability, and endless creative possibilities, ensuring they remain competitive in an ever-changing landscape. Whether in jeans manufacturing or activewear production, the double needle chain stitch machine is indeed a cornerstone of modern apparel creation, embodying the intersection of technology and artistry in the world of fashion.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025