Jan . 13, 2025 15:52

Back to list

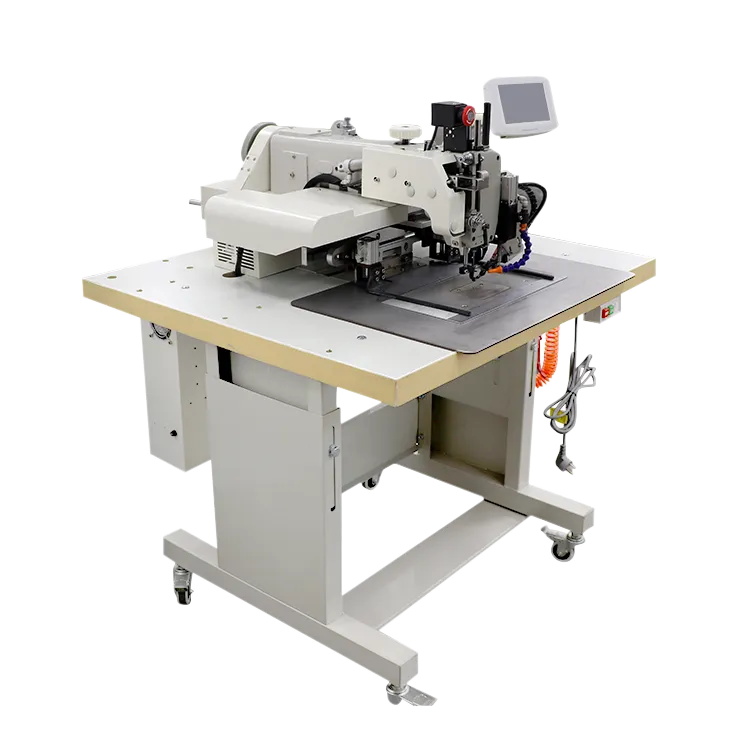

double needle bar machine

The double needle bar machine stands as an indispensable tool in the textile manufacturing industry, exuding an exceptional blend of precision and efficiency. This machine, known for its intricate stitching capability, serves as a cornerstone for producing high-quality knit fabrics that require durability and refined craftsmanship. With its dual-bar feature, the machine can execute a variety of stitches, making it versatile for manufacturers aiming to produce diverse fabric styles.

Authoritative sources in textile machinery endorse the double needle bar machine for its contribution to high-volume, high-speed production environments. These endorsements stem from extensive research and field studies demonstrating the machine's capability to maintain high standards of fabric quality under rigorous conditions. End users frequently report substantial ROIs, attributing cost efficiencies to the machine’s low idle time and swift adaptability to various knitting tasks. Brand reputation plays a significant role in choosing a double needle bar machine. Consumers are advised to evaluate manufacturers known for precision engineering and long-standing commitments to technological advancements. With testimonials and success stories from established textile firms, prospective buyers can ascertain the machine's reputation and gauge its suitability for their specific manufacturing needs. In conclusion, the double needle bar machine embodies a synergy of robust engineering and versatile functionality. Its ability to deliver high-quality knit fabrics while optimizing operational efficiency makes it a valuable asset in any textile production facility. Companies equipped with this technology can expect to meet demanding market standards, foster innovation, and ensure competitiveness. By investing in the kind of machinery that this represents, textile manufacturers can reinforce their market position with assurance in quality and reliability.

Authoritative sources in textile machinery endorse the double needle bar machine for its contribution to high-volume, high-speed production environments. These endorsements stem from extensive research and field studies demonstrating the machine's capability to maintain high standards of fabric quality under rigorous conditions. End users frequently report substantial ROIs, attributing cost efficiencies to the machine’s low idle time and swift adaptability to various knitting tasks. Brand reputation plays a significant role in choosing a double needle bar machine. Consumers are advised to evaluate manufacturers known for precision engineering and long-standing commitments to technological advancements. With testimonials and success stories from established textile firms, prospective buyers can ascertain the machine's reputation and gauge its suitability for their specific manufacturing needs. In conclusion, the double needle bar machine embodies a synergy of robust engineering and versatile functionality. Its ability to deliver high-quality knit fabrics while optimizing operational efficiency makes it a valuable asset in any textile production facility. Companies equipped with this technology can expect to meet demanding market standards, foster innovation, and ensure competitiveness. By investing in the kind of machinery that this represents, textile manufacturers can reinforce their market position with assurance in quality and reliability.

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025