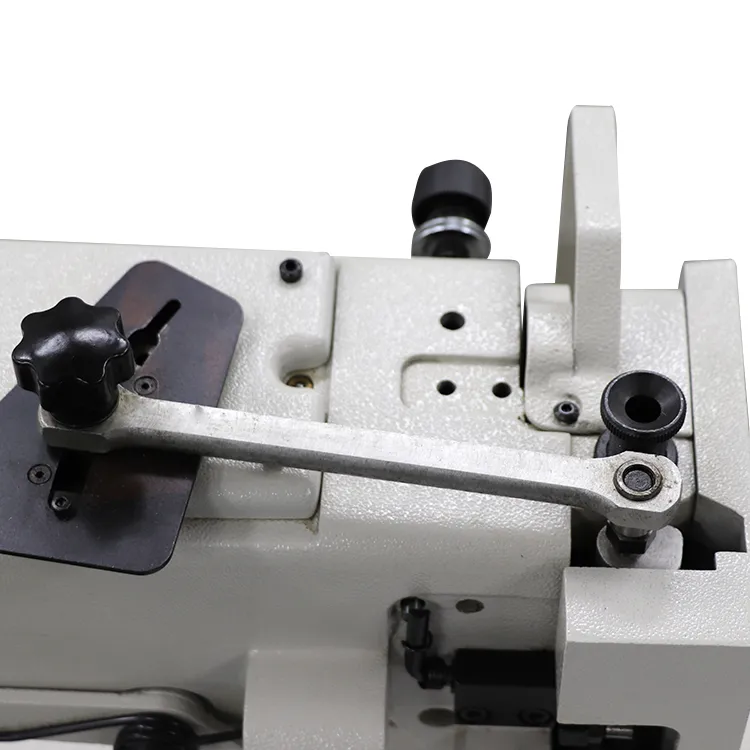

double needle bag closer machine

The Double Needle Bag Closer Machine A Comprehensive Overview

In the world of manufacturing and packaging, efficiency and precision are paramount. One machine that stands out for its capability to enhance both is the double needle bag closer. This specialized equipment is crucial for industries involved in packaging grains, fertilizers, chemicals, and various other bulk materials. The double needle bag closer offers enhanced stitching strength and durability, ensuring that products remain secure during transport and storage.

Understanding the Functionality

The double needle bag closer operates using two needles that stitch the bag simultaneously. This dual-needle system provides several advantages over single-needle machines. First and foremost, it creates a stronger seam, making it especially suitable for heavy-duty bags that need to withstand stress. The double stitch not only offers superior strength but also enhances the overall aesthetic of the closure, providing a professional finish that is crucial for branded products.

The machine’s design allows it to work on a variety of materials, ranging from burlap and polypropylene to woven and laminated fabrics. This versatility is one of its key selling points, as businesses often deal with different kinds of packaging depending on their specific needs. Adjustments can typically be made to accommodate different bag sizes, thread types, and stitching patterns.

Key Features

1. Durability and Longevity Constructed from high-quality materials, the double needle bag closer is built to withstand rigorous use. Its sturdy design minimizes the need for repairs and replacements, thereby reducing maintenance costs for businesses.

2. Operational Efficiency With the capability to close bags quickly and effectively, the machine significantly reduces labor time. High-speed operation ensures that packaging processes remain constant and that productivity is maximized.

double needle bag closer machine

3. Adjustable Settings Most double needle bag closers come with adjustable settings. Operators can modify the stitch length, tension, and speed to meet specific requirements, allowing for customization based on the type of material being used.

4. User-Friendly Interface Modern models are equipped with intuitive controls that simplify operation. This feature enables workers to learn how to use the machine quickly, thereby reducing training time and easing the transition for new employees.

5. Safety Features Safety is a top priority in any manufacturing environment. The latest models of double needle bag closers are equipped with safety guards and shut-off mechanisms to prevent accidents during operation.

Applications Across Industries

The versatility of the double needle bag closer makes it applicable in numerous industries. In agriculture, for example, it is commonly used for packaging seeds, grains, and fertilizers, preventing spillage and contamination. The construction industry uses this equipment for closing bags filled with sands, concrete, or other bulk materials. Moreover, the food industry leverages this machine for packaging powdered products, such as flour and sugar, where sanitary standards must be upheld.

Additionally, chemical companies find the double needle bag closer invaluable for packaging hazardous materials, ensuring that closures are tight and secure. This feature not only protects the product but also ensures compliance with safety regulations regarding the transport of chemicals.

Conclusion

In conclusion, the double needle bag closer machine stands as an essential tool in the packaging industry, offering efficiency, durability, and reliability. Its ability to create strong, secure seams enhances product safety during transport and storage, making it a critical investment for businesses across various sectors. As industries continue to evolve and demand higher productivity levels, the double needle bag closer is poised to remain at the forefront of packaging technology, seamlessly combining functionality with user-oriented design. Whether for small-scale operations or large manufacturing plants, its contributions to streamlined processes and secure packaging cannot be overstated.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025