Cylinder Bed Walking Foot Sewing Machine for Enhanced Fabric Handling

The Cylinder Walking Foot Sewing Machine A Revolution in Textile Manufacturing

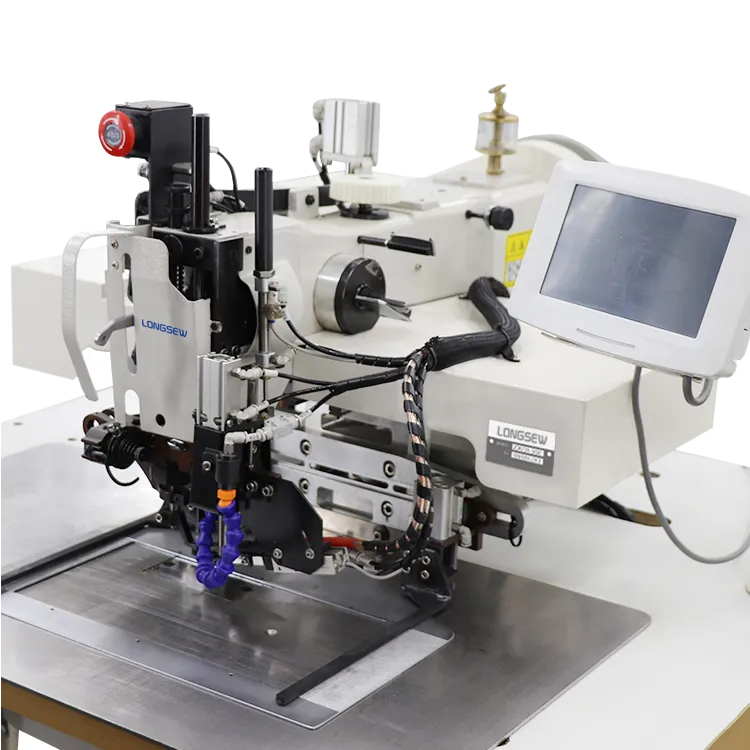

In the ever-evolving world of textile manufacturing, the introduction of specialized sewing machines has played a pivotal role in enhancing efficiency, precision, and quality. Among these innovations, the cylinder walking foot sewing machine stands out as a game-changer. This machine is specifically designed to tackle the challenges associated with sewing cylindrical and difficult-to-manage materials, making it an indispensable tool in various industries such as upholstery, leather goods, and garment production.

Understanding the Cylinder Walking Foot Sewing Machine

At its core, the cylinder walking foot sewing machine features a unique cylinder-shaped bed, allowing for easy access to tubular items, such as sleeves, cuffs, collars, and hems. This design is particularly advantageous when sewing materials that require intricate and precise handling. Unlike traditional flat-bed sewing machines, the cylinder bed facilitates the manipulation of fabric around curves and angles, significantly reducing the risk of puckering and ensuring a professional finish.

The term walking foot refers to the machine's presser foot mechanism, which moves the fabric through the sewing process in a coordinated manner. This feature allows for the even feeding of multiple layers of fabric, preventing the top layer from slipping and ensuring that all layers are stitched together smoothly. This is especially crucial in heavy materials, such as leather or denim, which can be difficult to manage without proper feeding mechanisms.

Applications of the Cylinder Walking Foot Sewing Machine

The versatility of the cylinder walking foot sewing machine makes it suitable for a wide range of applications. In the upholstery industry, it is commonly used to sew heavy-duty items like sofas, chairs, and cushions. The ability to handle thick materials means that upholsterers can work with a variety of fabrics, including leather, vinyl, and canvas, without compromising on quality.

In garment manufacturing, this machine is invaluable for sewing cylindrical garments, such as pants, shirts, and sportswear. The precision of the walking foot helps ensure that hems and seams are finished perfectly, contributing to the overall aesthetic and durability of the garment.

The leather goods industry also benefits significantly from this technology

. Whether crafting handbags, wallets, or belts, the cylinder walking foot sewing machine provides the necessary control to create intricate designs and handle thickness variations with ease.cylinder walking foot sewing machine

Advantages of Using a Cylinder Walking Foot Sewing Machine

1. Precision and Control The unique walking foot mechanism ensures that all layers of fabric are fed evenly, reducing the risk of misalignment and ensuring consistent stitch quality.

2. Versatility This machine can handle a wide variety of materials, including heavy fabrics, making it suitable for multiple applications across different industries.

3. Enhanced Productivity The efficient feeding mechanism allows for continuous sewing without interruption, thereby increasing production speed. This is particularly beneficial in high-volume settings where time is of the essence.

4. Reduced Fabric Damage Unlike traditional presser feet that can create drag, the walking foot minimizes friction on the fabric, reducing the chances of damage or distortion during the sewing process.

5. Ease of Use Many models come equipped with user-friendly features, including adjustable stitch length and pressure, making them accessible for both novice and experienced sewers.

Conclusion

The cylinder walking foot sewing machine is a revolutionary tool in the textile manufacturing industry, offering unmatched versatility and precision. Its ability to handle cylindrical shapes and thick materials has made it a favorite among professionals in upholstery, garment production, and leather goods. As the demand for high-quality, durable products continues to rise, the cylinder walking foot sewing machine will undoubtedly remain a vital asset for manufacturers looking to enhance their production capabilities and deliver exceptional craftsmanship.

In an age where efficiency, speed, and quality are paramount, investing in specialized sewing technology like the cylinder walking foot sewing machine is not just beneficial—it's essential for staying competitive in the textile industry. As we look to the future, this machine will continue to evolve, incorporating advanced features that further streamline the sewing process, making it an indispensable part of modern textile production.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025