Cylinder Bed Industrial Sewing Machines for Versatile Fabric Manipulation and Enhanced Stitch Quality

The Cylinder Industrial Sewing Machine Precision and Versatility in Textile Manufacturing

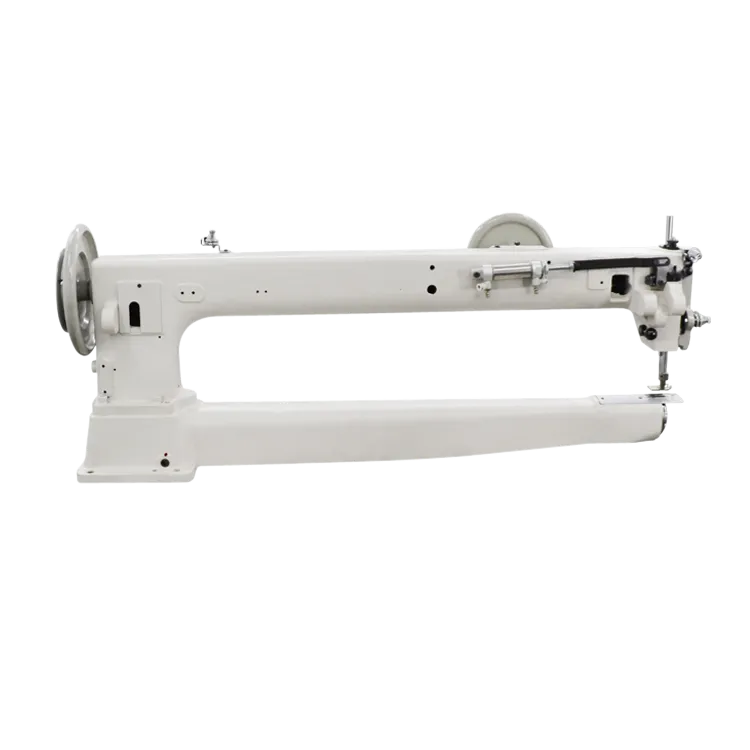

In the ever-evolving world of textile manufacturing, precision and efficiency are paramount. Among the various types of sewing machines that have revolutionized the industry, the cylinder industrial sewing machine stands out for its unique design and functionality. This machine has become a vital tool for garment manufacturers and upholsterers, allowing them to create intricate designs with excellent accuracy on cylindrical and tubular fabrics.

Unique Design Features

At the heart of the cylinder industrial sewing machine's appeal is its distinct cylindrical arm. Unlike traditional flatbed sewing machines, the cylindrical design allows for easier manipulation of fabric, particularly when working with items like sleeves, cuffs, and legs of trousers. This feature is especially advantageous for mass-production environments where speed and efficiency are essential.

The cylindrical arm enables operators to sew around curved surfaces, making it ideal for producing fitted garments, bags, and other three-dimensional textile products. This flexibility translates into a significant reduction in production time while maintaining high-quality standards, a crucial factor in today’s competitive market.

Enhanced Capabilities

One of the key advantages of the cylinder industrial sewing machine is its ability to handle a wide variety of materials. From lightweight fabrics to heavy-duty textiles, this machine adapts seamlessly. The powerful motor and robust build make it capable of stitching through multiple layers of fabric without compromising on stitch quality.

Moreover, many cylinder sewing machines come equipped with multiple stitch options, including straight, zigzag, and overlock stitches. This versatility allows businesses to diversify their product lines, from simple garments to complex designs adorned with decorative stitching. As a result, manufacturers can respond quickly to changing fashion trends and customer demands.

cylinder industrial sewing machine

Applications in the Industry

The applications of cylinder industrial sewing machines are vast. In the garment sector, they are widely used for sewing collars, sleeves, and pockets. Upholstery manufacturers benefit from these machines when creating furniture coverings and automotive interiors, where the ability to navigate curves and seams is crucial.

Additionally, in the footwear industry, the cylindrical design allows for the efficient assembly of shoe parts, including tops and linings, which often require intricate stitching techniques. The adaptability of cylinder sewing machines makes them indispensable for businesses aiming to produce high-quality products efficiently.

Maintenance and Sustainability

Maintaining a cylinder industrial sewing machine is essential for ensuring its longevity and optimal performance. Regular cleaning, oiling moving parts, and checking for rapid wear and tear can prevent costly downtimes. Many manufacturers also emphasize the importance of operator training to ensure that staff can utilize the machine’s capabilities fully and recognize when maintenance is required.

Sustainability is becoming increasingly important in textile manufacturing, and the efficient operation of cylinder industrial sewing machines aligns with this trend. By reducing fabric waste through precise stitching and enabling the production of durable goods, these machines contribute to a more sustainable manufacturing process. Furthermore, manufacturers are exploring eco-friendly materials and practices, making the integration of advanced machinery an important step toward greener production.

Conclusion

In conclusion, the cylinder industrial sewing machine is a critical asset in the textile manufacturing landscape. Its unique design, enhanced capabilities, and wide-ranging applications make it an essential tool for a variety of industries. As manufacturers continue to seek ways to improve efficiency and sustainability, the cylinder sewing machine will undoubtedly remain at the forefront, driving innovation and quality in garment and textile production. Embracing this advanced machinery not only positions businesses for success in today's market but also contributes to a more sustainable future in manufacturing.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025