Cylinder Bed Industrial Sewing Machines for Versatile Fabric Handling and Efficiency

The Evolution and Significance of Cylinder Industrial Sewing Machines

In the world of textile manufacturing, industrial sewing machines play a pivotal role in ensuring efficiency, precision, and productivity. Among the various types of industrial sewing machines, the cylinder bed sewing machine stands out for its unique design and versatility. This article delves into the intricacies of cylinder industrial sewing machines, exploring their features, advantages, applications, and the significant role they play in modern garment production.

Understanding Cylinder Industrial Sewing Machines

The primary distinguishing feature of a cylinder industrial sewing machine is its cylindrical bed. Unlike flatbed sewing machines, the cylinder bed’s design allows for easy handling and manipulation of tubular fabrics, such as sleeves, cuffs, and legs of pants. This design enables manufacturers to sew areas that are typically challenging to reach with traditional sewing machines. The cylindrical shape provides additional workspace, allowing for greater flexibility in fabric movement and positioning.

Key Features

1. Feed Mechanism Cylinder industrial sewing machines are often equipped with advanced feed mechanisms, such as walking feet or needle feed systems. These features help ensure that layers of fabric are fed evenly through the machine, preventing ruckling or misalignment during the sewing process.

2. Stitch Variety Many cylinder sewing machines offer a variety of stitching options, including lock stitches, chain stitches, and cover stitches. This multiform capability allows manufacturers to handle different fabrics and achieve the desired seam finishes suitable for various garment types.

3. Durability and Speed Designed for high-volume production, cylinder industrial sewing machines boast durability and the ability to operate at high speeds. This makes them ideal for large-scale manufacturing processes where time efficiency and reliability are crucial.

4. Ease of Use Modern cylinder sewing machines often come with user-friendly controls and automated features, such as thread trimming and programmable stitch lengths. These enhancements simplify operation and reduce manual intervention, further boosting productivity.

Advantages of Cylinder Industrial Sewing Machines

The advantages of cylinder industrial sewing machines are manifold

1. Enhanced Precision The cylindrical bed allows for better visibility and control over the sewing area, leading to improved stitch precision. This is particularly beneficial when working with intricate designs or closely-fitting garments.

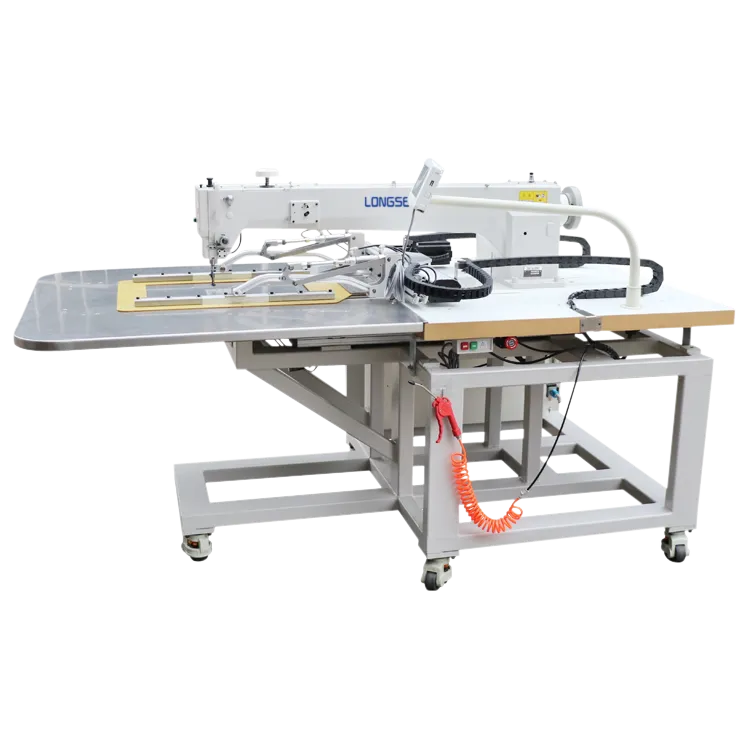

cylinder industrial sewing machine

2. Greater Flexibility The ability to handle tubular fabrics with ease makes cylinder machines invaluable for manufacturers focused on producing items such as uniforms, sportswear, and other fitted garments. Their flexibility caters to diverse production needs.

3. Reduced Workforce Strain The ergonomic design of cylinder sewing machines minimizes the physical strain on workers. Operators can easily maneuver fabrics without excessive bending or stretching, promoting a safer and more comfortable working environment.

4. Increased Production Efficiency With their high-speed capabilities and efficient feeding mechanisms, cylinder sewing machines significantly enhance production rates. This translates to lower operational costs for manufacturers and faster turnaround times for clients.

Applications in Garment Production

Cylinder industrial sewing machines are widely used across various segments of the garment industry. Here are a few key applications

1. Sportswear Manufacturing The flexibility and speed of cylinder sewing machines make them perfect for producing athletic wear that requires both stretch and durability. The ability to manage multiple elastic fabrics seamlessly ensures the production of high-performance sports garments.

2. Denim Production When working with denim, precise stitch placement is crucial. Cylinder machines handle the thick layers of denim efficiently, ensuring sturdy and aesthetically pleasing seams suitable for jeans and jackets.

3. Children’s Clothing Producing children's clothing often involves sewing smaller, tubular sections like sleeves and pant legs. Cylinder machines facilitate quicker production cycles without compromising on quality or safety.

4. Uniform Manufacturers Many uniforms require specialized sewing techniques that demand precision and efficiency. Cylinder machines are integral in ensuring that these garments are produced to exact specifications, which is vital in industries such as healthcare and hospitality.

Conclusion

In summary, cylinder industrial sewing machines represent a significant advancement in the realm of garment production. Their unique design, versatility, and efficiency cater to the diverse needs of manufacturers, allowing for high-quality outputs in various applications. As the fashion and textile industries continue to evolve, the cylinder industrial sewing machine will undoubtedly remain a crucial component in achieving excellence in garment manufacturing.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025