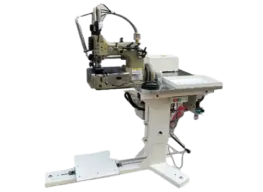

cylinder bed industrial sewing machine

The Importance of Cylinder Bed Industrial Sewing Machines in Modern Textile Production

In the realm of textile manufacturing, the efficiency and precision of sewing machines play a pivotal role in determining the quality of the final product. Amongst the array of sewing machines available, the cylinder bed industrial sewing machine stands out for its unique design and versatility. This type of sewing machine is particularly advantageous for working with cylindrical and tubular fabrics, making it an indispensable tool in industries such as garment production and upholstery.

The cylinder bed design features a protruding cylindrical surface that allows for greater maneuverability when handling complex shapes and contours. This is especially beneficial when sewing items like sleeves, cuffs, and other curved sections that may be challenging for flatbed machines. The ability to access tight spaces and perform intricate stitching ensures that manufacturers can achieve high-quality finishes and maintain efficient workflow.

One of the key advantages of cylinder bed industrial sewing machines is their adaptability to various materials. Whether working with lightweight fabrics or heavy-duty textiles, these machines can be equipped with the appropriate needle and thread configurations to accommodate the specific requirements of each project. This versatility is crucial in today’s fast-paced fashion industry, where quick turnarounds and diverse product ranges are essential for staying competitive.

cylinder bed industrial sewing machine

Moreover, the robust design of cylinder bed machines ensures durability and longevity, making them a wise investment for businesses. They are built to withstand the rigors of continuous operation, offering reliability that manufacturers can count on during peak production times. The high-speed capabilities of these machines enable greater output, contributing to increased productivity without compromising on quality.

In addition to functionality, modern cylinder bed industrial sewing machines come equipped with advanced technological features. Many models now incorporate computerized systems that allow for precise control over stitches and patterns. This automation not only enhances efficiency but also reduces the likelihood of human error, further ensuring consistent quality across large production runs.

Furthermore, the ergonomic design of these machines promotes comfort for operators, allowing them to work for extended periods without strain. Features such as adjustable heights, smooth pedal operation, and streamlined controls contribute to a more pleasant working environment, ultimately leading to improved employee satisfaction and productivity.

In conclusion, cylinder bed industrial sewing machines are essential tools in the modern textile industry, providing the flexibility, durability, and technological advancements necessary for high-quality sewing. Their unique design allows for efficient handling of intricate shapes, making them the preferred choice for manufacturers looking to elevate their production capabilities. As the demand for diverse and innovative textile products continues to grow, the importance of these specialized sewing machines will undoubtedly remain at the forefront of industrial manufacturing.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025