cylinder arm sewing machine leather

Exploring the Cylinder Arm Sewing Machine for Leatherwork

In the world of leather craftsmanship, precision and versatility are paramount. The cylinder arm sewing machine has emerged as a vital tool for artisans and manufacturers alike, revolutionizing the way leather goods are produced. This article delves into the significance, functionality, and benefits of using cylinder arm sewing machines specifically designed for leatherwork.

What is a Cylinder Arm Sewing Machine?

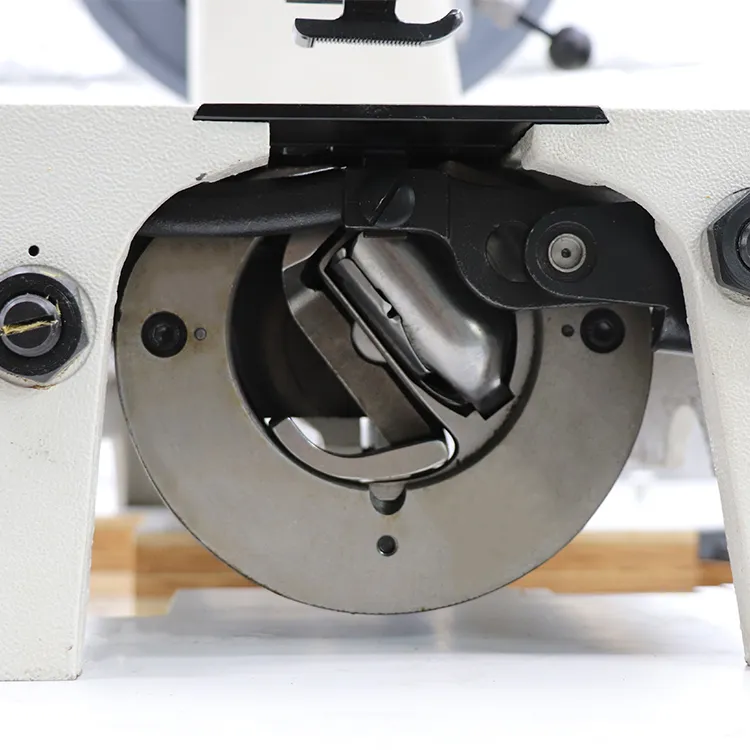

A cylinder arm sewing machine is a specific type of industrial sewing machine characterized by its unique arm design. Unlike the traditional flatbed sewing machines, the cylinder arm features a cylindrical surface that allows the user to easily work on round or tubular items. This design is particularly advantageous for sewing leather, which often requires handling complex shapes, such as the arms of leather bags, shoes, or belts.

Why Choose a Cylinder Arm Sewing Machine for Leather?

1. Greater Access The cylindrical arm provides improved accessibility to hard-to-reach areas, making it easier to sew cuffs, collars, and other intricate details common in leather projects. This benefit is crucial for achieving high-quality finishes on leather goods, where precision is key.

2. Flexibility in Handling The cylinder arm allows for better maneuverability of the leather pieces being sewn. Artisans can rotate and position the leather more easily around the machine, facilitating the sewing of curves and corners that would be challenging on a flatbed machine.

3. Robust Construction Cylinder arm sewing machines designed for leather are built to withstand the heavy-duty nature of leather projects. They often come equipped with powerful motors and durable feed mechanisms, which help manage the thickness and density of leather materials.

4. Variety of Stitches Many cylinder arm machines come with multiple stitching options, allowing for decorative stitching, reinforced seams, and specialized techniques that enhance the final product's aesthetic and structural integrity. This flexibility is essential for custom leatherwork, where unique designs are often requested.

cylinder arm sewing machine leather

Key Features to Consider

When selecting a cylinder arm sewing machine for leatherwork, several features should be taken into account

- Walking Foot Mechanism This feature helps to simultaneously move the top and bottom layers of leather, preventing them from slipping and ensuring even stitching.

- Needle System Compatibility Verify the needle system used by the machine to ensure it can accommodate various needle sizes suitable for different leather thicknesses.

- Industrial Build Quality Look for machines built with high-quality materials to withstand the demands of sewing leather, ensuring longevity and reliability.

- Adjustable Tension Controls Tension adjustments are crucial for working with leather, as improper tension can lead to issues such as skipped stitches or puckering.

Conclusion

The cylinder arm sewing machine stands out as an indispensable tool for anyone serious about leather craftsmanship. Its unique design and functionality cater specifically to the intricate and challenging aspects of leatherwork, enabling artisans to create high-quality products with efficiency and precision. As the demand for bespoke leather goods continues to grow, investing in a cylinder arm sewing machine may not only enhance the quality of work but also expand creative possibilities. Whether for a professional enterprise or passionate hobbyists, this machine represents a perfect blend of tradition and technology, helping to preserve the timeless art of leathercraft while accommodating modern production needs.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025