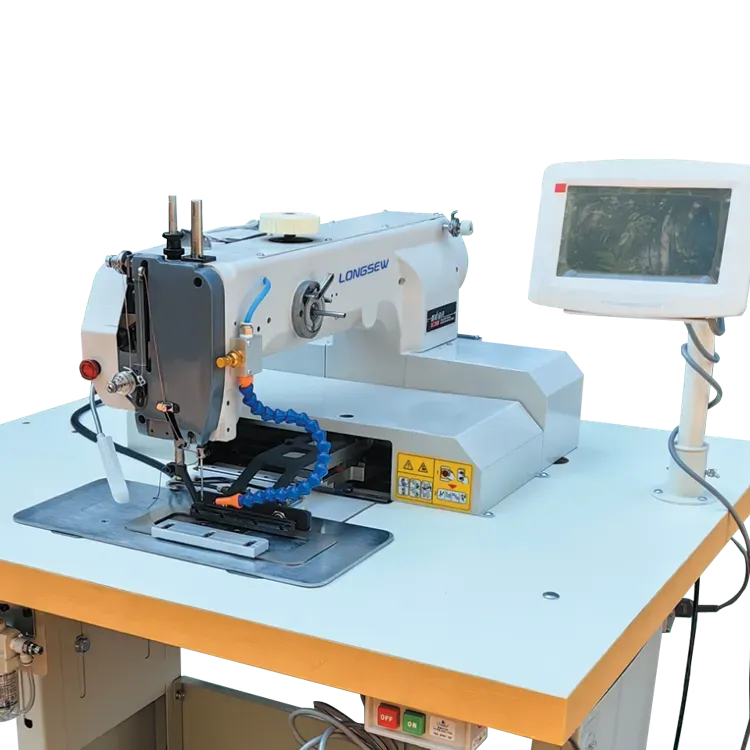

cylinder arm sewing machine

The Evolution and Efficiency of Cylinder Arm Sewing Machines

In the world of garment manufacturing and textile production, sewing machines have continually evolved to meet the challenges posed by different types of fabric and various sewing requirements. Among these innovations, the cylinder arm sewing machine stands out for its unique design and exceptional versatility. This article will explore the features, advantages, applications, and future potential of cylinder arm sewing machines in the textile industry.

Understanding Cylinder Arm Sewing Machines

A cylinder arm sewing machine is characterized by its cylindrical, protruding arm that allows for ease of access to the fabric. Unlike traditional flatbed models, the cylinder arm's design is particularly conducive to sewing tubular materials or other complex shapes. This machine typically has a rounded arm that extends from the base, providing operators with a greater range of movement and control when working with items like sleeves, cuffs, and bags.

Key Features and Functions

One of the most significant advantages of cylinder arm sewing machines is their ability to handle intricate sewing tasks with precision. The cylindrical arm allows operators to sew around curved surfaces effortlessly, making it particularly valuable in the production of fitted garments. Most cylinder arm machines also possess features like adjustable stitch length, various stitch patterns, and heavy-duty capabilities suited for thick or layered materials.

Many modern cylinder arm sewing machines come equipped with advanced technology, including electronic controls, programmable options, and automatic thread trimming

. These features enhance efficiency, reduce operator fatigue, and improve overall production quality. Additionally, the machines can be adapted for various sewing techniques such as plain, zigzag, or overlock stitching, making them suitable for diverse applications.Applications in the Textile Industry

cylinder arm sewing machine

Cylinder arm sewing machines are employed across a broad spectrum of industries, including fashion, sportswear, and upholstery production. Their ability to tackle challenging sewing tasks makes them an ideal choice for companies specializing in high-end garments that require precision and a professional finish. For example, when sewing the armholes of a fitted jacket or the seams of an athletic garment, the cylinder arm's design allows for consistent stitching in hard-to-reach areas.

Furthermore, they are common in the production of leather goods, handbags, and various accessories, where detailed work is essential. The ability to manipulate fabric efficiently without compromising quality ensures that manufacturers can maintain high standards in their final products.

Advantages Over Traditional Sewing Machines

The cylinder arm sewing machine offers several advantages over traditional flatbed designs. The most notable is its capacity to sew around and inside cylindrical or tubular fabrics, which would be difficult for standard machines. Additionally, the free-arm design minimizes the likelihood of fabric bunching or misalignment, resulting in cleaner seams and consistent results.

Operators also benefit from improved ergonomics, as the design allows for a more natural sewing position. This feature is particularly beneficial during long production runs, as it helps reduce strain and the risk of repetitive motion injuries.

The Future of Cylinder Arm Sewing Machines

As technology advances, cylinder arm sewing machines are likely to become even more sophisticated. With the integration of automation and smart technology, we can expect to see machines capable of real-time monitoring and adjustable settings for enhanced precision. Moreover, the demand for sustainable and eco-friendly manufacturing practices will likely influence the development of more efficient machinery that minimizes waste and energy consumption.

In conclusion, the cylinder arm sewing machine has become an indispensable tool in the textile industry due to its unique design, versatility, and efficiency. As manufacturers continue to innovate and adapt to changing market demands, these machines will play a critical role in shaping the future of garment production, ensuring that quality and precision remain at the forefront of textile manufacturing. Whether you are a seasoned seamstress or a large-scale manufacturer, the cylinder arm sewing machine is a key asset for achieving excellence in sewing.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025