cutting line sewing

Understanding Cutting and Sewing in Garment Production

In the world of fashion and garment production, the efficiency and precision of cutting and sewing processes play a critical role in the overall success of creating high-quality apparel. The term “cutting line sewing” encapsulates an intricate process that not only emphasizes the importance of accurate cutting techniques but also illustrates how sewing seamlessly fits into the overall production workflow. This article delves into these concepts, discussing their significance, techniques, and the impact they have on the final product.

The Importance of Cutting

Cutting is the foundational step in the garment production process. It involves dividing fabric into specific shapes and sizes that correspond to the design of the garment. This initial stage is crucial because any error during cutting can lead to fabric wastage and increase production costs. There are various techniques employed in cutting, including manual cutting with scissors and electric cutting machines.

One of the key components of effective cutting is the preparation of cut plans and markers. Markers are templates that provide a layout for cutting multiple fabric pieces, ensuring that minimal waste occurs. They are meticulously crafted, taking into account the length and width of the fabric, the pattern design, and the size of the garments to be produced. The precision of these markers directly influences the efficiency of the cutting process and the material utilization rate.

Transition to Sewing

Once the fabric pieces are cut, they move into the sewing stage. This is where the individual components come together to form the final garment. Sewing can be as simple as joining two pieces of fabric or as complex as constructing multi-layered designs. The type of stitches, threading techniques, and finishing processes all contribute to the overall quality and appearance of the garment.

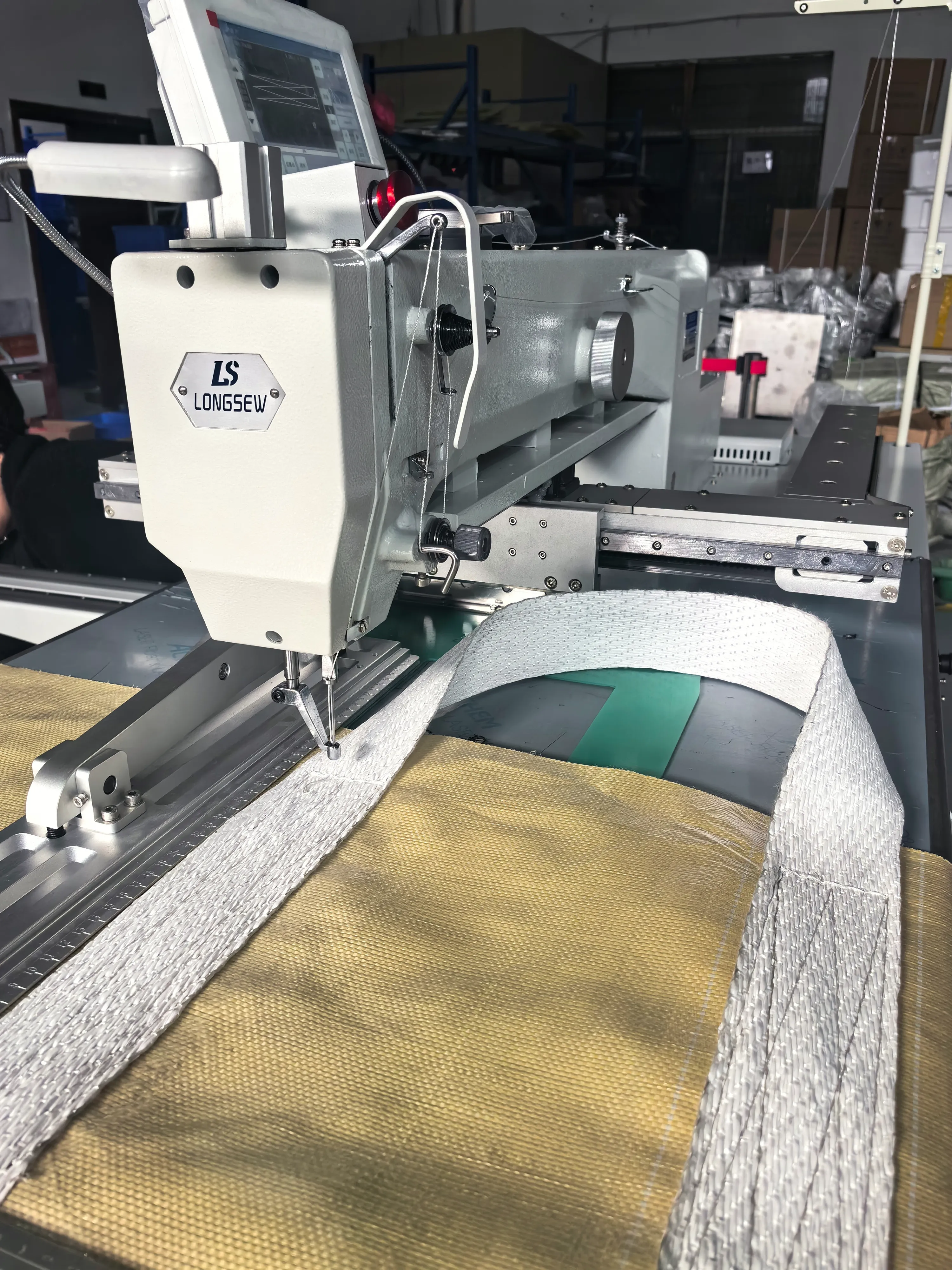

Sewing can be carried out using various machines depending on the fabric type and the design complexity. For instance, straight-stitch machines are commonly used for basic seams, while overlock machines are essential for finishing edges to prevent fraying. Advanced technologies like computer-controlled embroidery machines also play a significant role in adding embellishments to garments, demonstrating the vast capabilities within the sewing phase.

cutting line sewing

Techniques and Quality Control

To ensure that the cutting and sewing processes are executed to perfection, various quality control measures are put in place. Skilled workers are trained to inspect fabric for defects before cutting, ensuring that only high-quality materials proceed to the next step. Following sewing, garments undergo thorough inspections where seam allowances are checked, stitches are assessed for evenness, and the overall construction is evaluated against production specifications.

Moreover, it is crucial to establish a feedback loop between the cutting and sewing departments. Any discrepancies noted during the sewing process can provide insights into potential adjustments needed during cutting. This collaborative approach helps to enhance overall production efficiency, reduces errors, and ensures that the garments produced meet the desired standards of quality.

Sustainability Considerations

In recent years, the fashion industry has faced criticism regarding sustainability and environmental impact. As such, the cutting and sewing processes have adapted to incorporate more sustainable practices. This includes the use of eco-friendly fabrics, optimizing cutting plans to minimize waste, and employing techniques that require less energy and water during production.

In essence, cutting line sewing is not merely a technique but a critical pillar of garment production that requires precision, skill, and collaboration. As the fashion industry continues to evolve, the integration of innovative technologies and sustainable practices in cutting and sewing will be vital for future success. Understanding these processes better can inspire improvements that enhance efficiency, reduce waste, and ultimately lead to a more sustainable future for fashion.

Conclusion

In conclusion, the cutting and sewing stages of garment production are essential for creating high-quality apparel. From meticulous planning in the cutting phase to the skillful execution of sewing, each step of the process builds on its predecessor. By embracing advancements in technology and sustainability, the fashion industry can enhance its practices and create products that are not only aesthetically pleasing but also considerate of their environmental impact. As consumers become more aware of these practices, the demand for transparency and quality in garment production will only continue to grow.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025