Cost of Double Tailoring Machines for Efficient Fabric Production and Customization Solutions

Understanding the Cost of Double Tailoring Machines

The textile and garment industry has undergone significant changes over the years, driven by advancements in technology and shifts in consumer demand. Among the notable innovations is the double tailoring machine, a sophisticated piece of equipment that has revolutionized the way garments are produced. As the need for speed, precision, and flexibility in garment production increases, understanding the pricing of double tailoring machines becomes essential for manufacturers seeking to invest wisely.

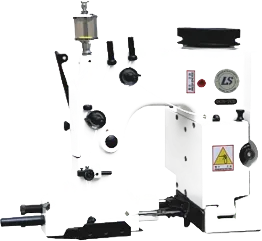

What is a Double Tailoring Machine?

A double tailoring machine is designed to enhance the efficiency of sewing processes. Unlike traditional sewing machines that often focus on single-layer stitching, double tailoring machines can handle multiple layers of fabric simultaneously. This capability makes them particularly valuable for complex garments that require various stitching techniques. These machines are equipped with advanced features, such as automatic thread trimming, computer-controlled stitch patterns, and ergonomic designs aimed at reducing operator fatigue.

Factors Influencing the Price

The price of double tailoring machines can vary widely based on several factors

1. Brand and Model Just like any other piece of machinery, the brand can significantly impact the price. Well-established brands with a reputation for quality and reliability often command higher prices. Additionally, newer models equipped with the latest technology may also be priced higher due to their advanced features.

2. Features and Specifications Machines equipped with additional features, such as programmable settings, multiple stitching options, and high-speed capabilities, tend to be more expensive. Manufacturers must evaluate their specific needs to determine which features will provide the best return on investment.

double tailoring machine price

3. Quality and Durability Investing in a high-quality machine that promises durability can save costs in the long run. Cheaper machines may require frequent repairs or replacements, ultimately leading to higher overall expenses.

4. Market Changes The textile industry is influenced by global market conditions, including fluctuations in supply chain costs and changes in consumer demand. Prices may vary based on market trends, availability of materials, and import/export taxes.

5. Technology and Innovation With rapid technological advancements, newer models may incorporate features such as IoT connectivity for data tracking and machine learning algorithms for improved performance. These innovative machines can come at a premium price.

Price Ranges

On average, the price of double tailoring machines can range from a few thousand to over twenty thousand dollars, depending on the factors mentioned above. Entry-level models suitable for small businesses might be available for around $5,000, while high-end industrial machines can exceed $15,000. Manufacturers should conduct thorough market research to find the best balance between their budget and the desired capabilities.

Conclusion

Investing in a double tailoring machine is a strategic decision that can lead to improved efficiency and product quality in the garment manufacturing process. By understanding the various factors that influence pricing, manufacturers can make informed decisions that align with their operational goals. Whether a small startup or a large-scale operation, selecting the right machine is crucial for staying competitive in an ever-evolving industry. As the demand for high-quality, custom garments grows, so too will the importance of investing in advanced manufacturing technologies like double tailoring machines. Thus, manufacturers must not only consider upfront costs but also the long-term benefits and returns these machines can provide.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025