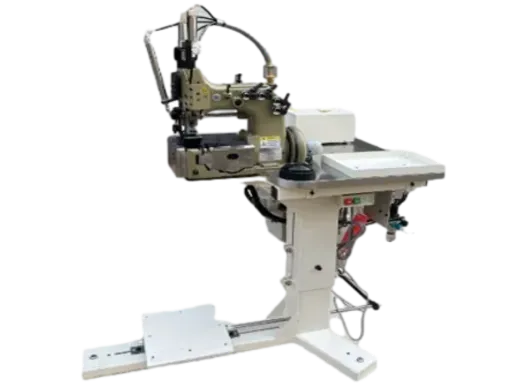

Industrial Sewing Machine with Compound Walking Foot for Enhanced Fabric Handling and Efficiency

The Compound Walking Foot Industrial Sewing Machine A Comprehensive Overview

In the world of industrial sewing, efficiency and precision are paramount. Among the various types of sewing machines designed for heavy-duty tasks, the compound walking foot industrial sewing machine stands out due to its unique mechanism and versatility. This article will delve into what this type of sewing machine is, its advantages, and its applications in various industries.

Understanding the Compound Walking Foot Mechanism

At its core, a compound walking foot industrial sewing machine is designed to handle multiple layers of heavy fabric with ease. The term walking foot refers to the feed mechanism that helps move the fabric during stitching. Unlike standard machines that rely solely on a lower feed dog to advance the fabric, the walking foot includes both the needle and the presser foot, creating a coordinated movement that ensures uniform feeding of materials.

The compound aspect of this machine refers to the dual function of the walking foot. While one foot pulls the fabric forward, the other remains stationary, allowing for more control and accuracy. This feature is particularly beneficial when working with thick materials such as leather, canvas, or upholstery fabrics, as it minimizes the risk of fabric slipping or puckering, a common issue with other machines.

Benefits of Using a Compound Walking Foot Industrial Sewing Machine

1. Versatility One of the major advantages of the compound walking foot machine is its adaptability to various fabric types. From thick leather used in leather goods manufacturing to lightweight materials for garment production, this machine can handle a wide range of textiles.

2. Precision The synchronized movement of the walking foot ensures that fabric layers are fed evenly, contributing to precise stitches and a professional finish. This is crucial in industries where appearance and quality are essential.

3. Durability Built for heavy-duty tasks, these machines are designed to withstand rigorous use. They are constructed from robust materials, making them ideal for high-volume production settings.

4. Reduced Labor Intensity The compound walking foot machine significantly reduces manual labor, as it automates the feeding process. This allows operators to focus on other critical aspects of sewing, improving overall efficiency.

compound walking foot industrial sewing machine

5. Ease of Use Modern compound walking foot machines often come equipped with user-friendly features, such as adjustable stitch length and tension control, making them accessible for both seasoned professionals and newcomers.

Applications Across Industries

The versatility and efficiency of compound walking foot industrial sewing machines make them indispensable in several sectors

- Leather Industry For producing bags, wallets, and belts, the machine's ability to work with thick materials and provide strong seams is invaluable.

- Upholstery In furniture manufacturing, these machines are used to sew together heavy upholstery fabrics and foam, ensuring a durable finish that can withstand everyday use.

- Garment Manufacturing In apparel production, especially when dealing with layered fabrics, the compound walking foot ensures that hems and seams are neat and consistent.

- Automotive Industry These machines are often employed to sew car interiors, including seats and upholstery, where strength and aesthetic appeal are crucial.

- Outdoor Gear and Sportswear From tents to backpacks, the machine's ability to handle multiple layers and diverse materials makes it vital for producing reliable outdoor gear.

Conclusion

The compound walking foot industrial sewing machine is a remarkable tool that bridges the gap between heavy-duty functionality and precision sewing. Its innovative design not only enhances productivity but also ensures high-quality finishes, making it a favorite among industries that require superior stitching capabilities. As technology continues to evolve, these machines are likely to incorporate even more features, solidifying their role as essential equipment in the sewing landscape. Whether for commercial or industrial use, investing in a compound walking foot industrial sewing machine is a decision that reflects a commitment to quality, efficiency, and craftsmanship.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025