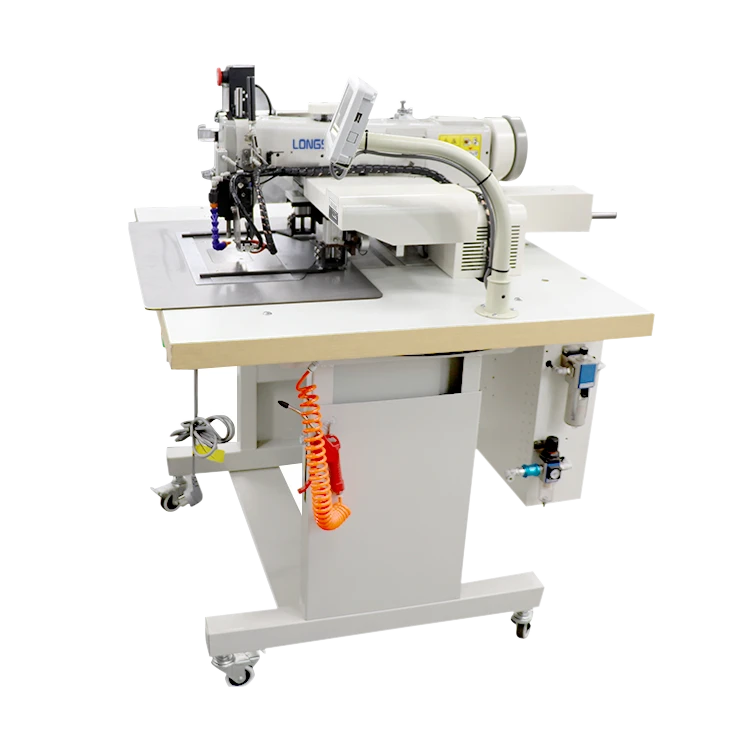

Heavy Duty Sewing Machine for Compound Feed Applications and Enhanced Performance

The Importance of Compound Feed Heavy Duty Sewing Machines in Modern Manufacturing

In the fast-paced world of manufacturing, the efficiency and quality of production processes are crucial. Among the various tools and machines employed, heavy-duty sewing machines with compound feed technology have emerged as indispensable assets in the textile and garment industries. These machines not only enhance productivity but also ensure a level of precision and durability that is essential for creating high-quality products.

Understanding Compound Feed Technology

Compound feed sewing machines operate on a unique mechanism that integrates the movement of the needle, the walking foot, and the presser foot. This synchronized action allows for the transport of multiple layers of fabric, which is vital when working with thick or heavy materials such as leather, canvas, or quilted fabrics. The ability to move the fabric effectively reduces slippage and ensures that all layers move together uniformly, leading to a consistent stitch quality.

This mechanism also significantly reduces the instances of puckering and distortion, which are common challenges when sewing heavier textiles. The compound feed technology provides feeding power from both the needle and the walking foot, ensuring that every stitch is precise and that the fabric is fed evenly. This is particularly important in industries that produce items requiring additional strength and durability, such as automotive upholstery, outdoor gear, and industrial workwear.

Advantages of Heavy-Duty Sewing Machines

1. Durability and Strength One of the most significant advantages of compound feed heavy-duty sewing machines is their ability to handle tough materials. Built with robust components, these machines can withstand the demands of continuous operation without compromising their performance.

2. Versatility While these machines are designed for heavy-duty applications, they are also versatile enough to handle a variety of sewing tasks. Whether it’s stitching thick leather or layered fabrics, manufacturers can count on their reliability across different projects. This saves both time and money as businesses can use one machine for various applications.

compound feed heavy duty sewing machine

3. Improved Stitch Quality The precision of stitch formation in compound feed machines is remarkable. They produce strong, undistorted seams, which are crucial for the quality of finished products. This advantage not only enhances the aesthetic appeal but also contributes to the longevity of the items produced.

4. Increased Efficiency The operational speed of heavy-duty sewing machines allows for a quick turnaround on projects, which is essential in a competitive market. Manufacturers can produce more within shorter timelines, leading to higher output and increased profitability.

Applications in Various Industries

Heavy-duty compound feed sewing machines find applications across multiple sectors. In the fashion and apparel industry, they are essential for producing outerwear, workwear, and activewear that require durability. In upholstery, these machines help create upholstered furniture, vehicle interiors, and home décor that can withstand wear and tear.

Additionally, industries involved in manufacturing gear for outdoor activities, such as tents, backpacks, and hiking clothing, heavily rely on the robust capabilities of these machines to create products that are not only functional but also long-lasting.

Conclusion

In conclusion, compound feed heavy-duty sewing machines play a pivotal role in modern manufacturing, especially in sectors that demand high-quality stitching and durability. Their ability to handle thick materials efficiently while ensuring superior stitch quality makes them invaluable assets for any manufacturer. As industries continue to evolve and demand flexibility and efficiency, investing in advanced sewing technology such as compound feed machines is increasingly becoming a necessity rather than a luxury. Embracing this technology will not only enhance productivity but also ensure that manufacturers maintain a competitive edge in a dynamic market.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025