commercial sewing machine needles

Understanding Commercial Sewing Machine Needles

In the world of sewing, the needle is often considered one of the most critical components of any sewing machine, especially for commercial purposes. Professional-grade sewing machines are commonly used in various industries, from garment manufacturing to upholstery, and having the right needle can make a significant difference in the quality and efficiency of the work. This article delves into the types, sizes, and features of commercial sewing machine needles, emphasizing how their selection can enhance productivity and output quality.

Types of Commercial Sewing Machine Needles

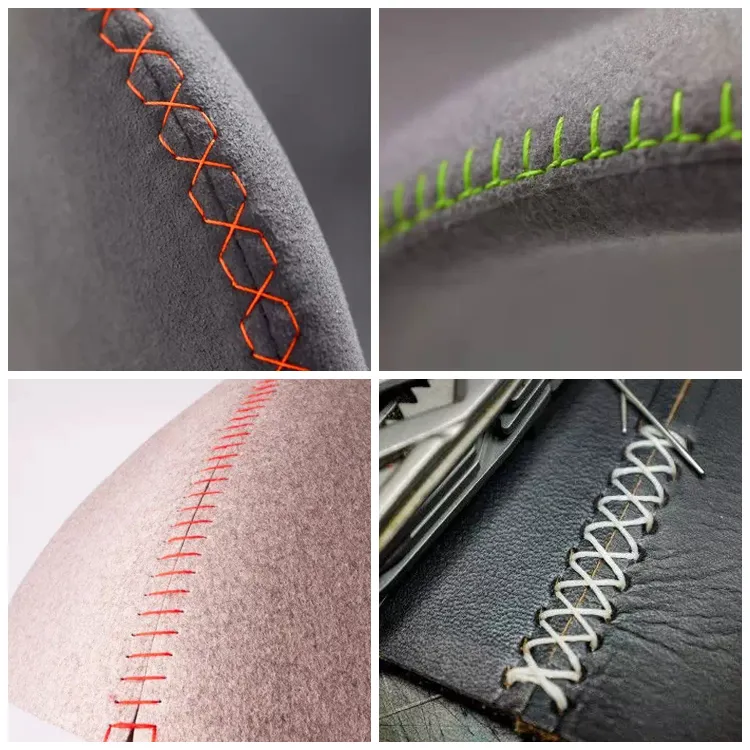

Commercial sewing machine needles come in various types, each designed for specific purposes. The most common needle types include

1. Universal Needles These are versatile needles suitable for a variety of fabrics. They have a slightly rounded point that allows them to sew woven and knit fabrics with ease.

2. Ballpoint Needles Specifically designed for knit fabrics, ballpoint needles have a rounded tip that prevents damage to the fibers. They are ideal for sewing on jersey, stretch fabrics, and other materials that can be easily snagged.

3. Sharps Needles As the name suggests, these needles have a very sharp point, making them perfect for sewing fine fabrics like silk or delicate materials that require precision.

4. Jeans/Denim Needles Equipped with a strong shaft and a thick, sharp point, these needles are designed to penetrate heavy fabrics such as denim and multiple layers of fabric. They are essential for construction work involving heavy-duty materials.

5. Embroidery Needles These needles feature a larger eye to accommodate thicker embroidery threads, and their special design helps to reduce friction and prevent thread breakage during decorative stitching.

commercial sewing machine needles

6. Quilting Needles With a tapered point, quilting needles are designed to sew through multiple layers of fabric, making them perfect for quilters who work with thick layers.

Needle Sizes

Choosing the correct needle size is just as important as selecting the appropriate type. The size of a needle refers to its thickness, which is designated by a numerical system. In general, a lower number indicates a finer needle, while a higher number signifies a thicker one. For commercial use, it is common to find needle sizes ranging from 60/8 (fine) to 120/19 (heavy). Selecting the right size is crucial, as using a needle that is too fine can result in skipped stitches, whereas a needle that is too thick can cause fabric damage or breakage.

The Importance of Quality

Investing in high-quality commercial sewing machine needles can have a direct impact on both output quality and machine longevity. Cheaper needles may save money initially but can lead to issues such as thread breakage, fabric damage, and inconsistent stitching. High-quality needles are manufactured with precision and often feature advanced coatings to reduce friction and heat buildup during sewing.

Maintenance and Replacement

It's essential for businesses to regularly assess the condition of their sewing needles. Needles should be replaced frequently as even minor wear can lead to subpar stitching outcomes. A good practice is to change needles after every project or every eight hours of sewing, especially in a high-volume commercial environment.

Conclusion

In the commercial sewing industry, understanding the intricacies of sewing machine needles can optimize production processes and enhance the quality of finished products. By selecting the appropriate type and size of needle for specific projects, businesses can improve efficiency and achieve superior results. Therefore, investing time in learning about and choosing the right needles is a valuable practice for any sewing professional. Whether you are involved in garment construction, upholstery work, or any other textile-related endeavor, the right needle can make all the difference in your craft.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025