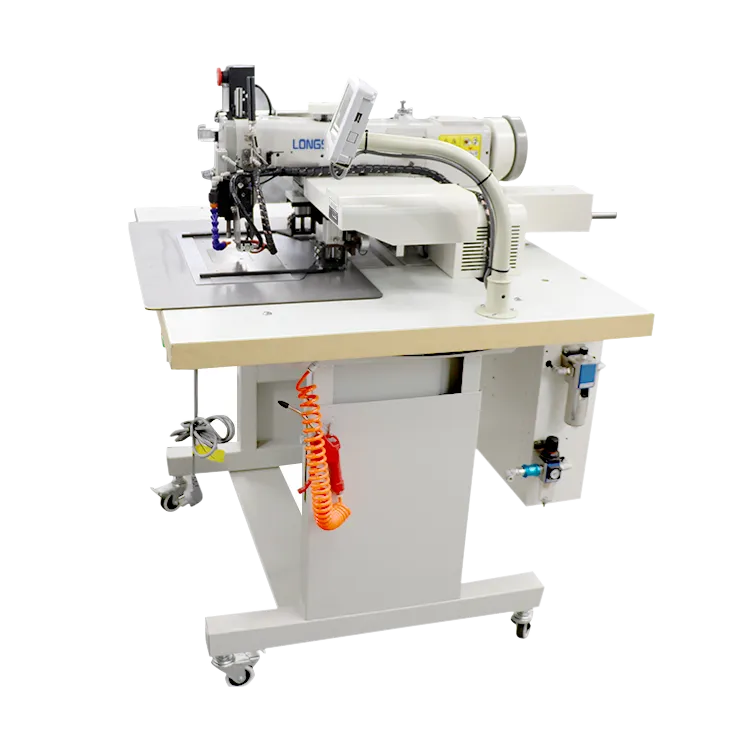

cnc tailoring machine

The Evolution and Impact of CNC Tailoring Machines

In the modern era of manufacturing and garment production, meticulous precision and efficiency are paramount. CNC (Computer Numerical Control) tailoring machines have revolutionized the way textiles are cut and shaped, significantly improving productivity and quality in the fashion and garment industry.

The Evolution and Impact of CNC Tailoring Machines

One of the primary advantages of CNC tailoring machines is their ability to minimize fabric waste. Traditional cutting methods often result in significant leftover material, whereas CNC machines optimize the layout of patterns on the fabric. By utilizing advanced algorithms, these machines systematically arrange the cutting patterns to ensure maximum material efficiency. This not only reduces costs associated with excess fabric but also promotes a more sustainable approach to garment manufacturing.

cnc tailoring machine

Moreover, CNC machines enhance production speed. With automated processes, tasks that once required hours of manual labor can often be completed in a fraction of the time. This acceleration enables manufacturers to meet the growing demand for fast fashion while maintaining high standards of precision. As a result, the industry can respond quicker to trends and changes in consumer preferences, ensuring that retailers can stock the latest styles without delay.

Another noteworthy aspect of CNC tailoring machines is their ability to produce highly detailed and complex designs. The integration of CAD (Computer-Aided Design) software allows designers to create intricate patterns that are easily translated into machine commands. This ease of design implementation encourages creativity and innovation, giving rise to unique garments that stand out in a crowded marketplace.

Furthermore, the adoption of CNC technology in tailoring contributes to improved working conditions. By automating repetitive and physically demanding tasks, CNC machines reduce the risk of fatigue and injury for workers, leading to a safer manufacturing environment. The focus can then shift to more skilled tasks that leverage human creativity and intuition.

In conclusion, CNC tailoring machines have become an indispensable asset in the garment manufacturing industry. They not only enhance precision and efficiency but also foster innovation and sustainability. As technology continues to evolve, the potential for further advancements in CNC tailoring machines remains promising, paving the way for a more efficient, creative, and sustainable future in fashion.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025