Advanced CNC Stitching Machines for Precision Fabric Assembly and Seamless Production

The Evolution and Significance of CNC Stitching Machines

In the realm of textile manufacturing, innovation is a key driver of efficiency and productivity. Among the most transformative advancements in recent years is the introduction of Computer Numerical Control (CNC) stitching machines. These state-of-the-art technologies have revolutionized the way garments and other textile products are created, providing numerous benefits over traditional stitching methods.

The Evolution and Significance of CNC Stitching Machines

One of the key advantages of CNC stitching machines is their ability to significantly increase production speed. Traditional sewing methods require skilled laborers to perform each stitch by hand, which can be time-consuming and prone to human error. With CNC technology, the entire process can be expedited, allowing manufacturers to meet tight deadlines and respond swiftly to market demands. This capability is particularly important in an era where fast fashion dominates the industry, necessitating rapid turnaround times without compromising on quality.

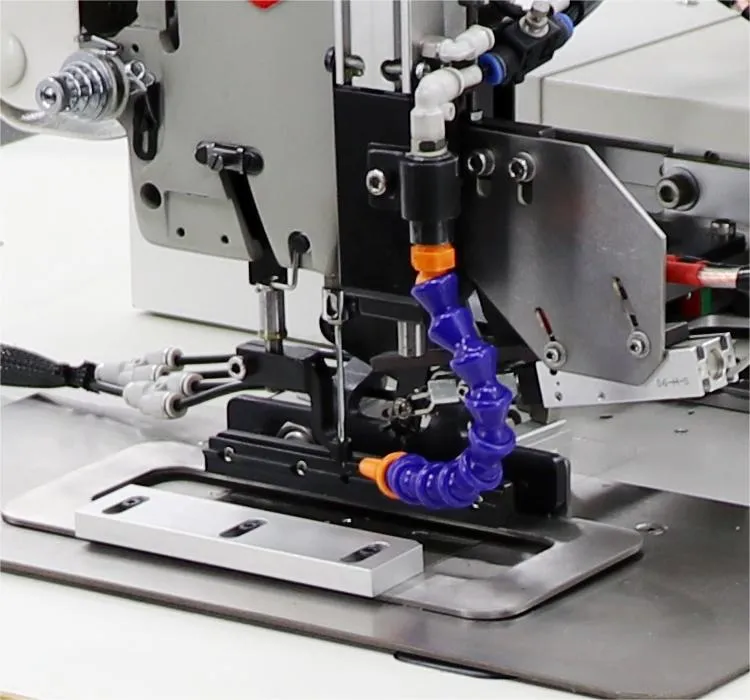

cnc stitching machine

Moreover, CNC stitching machines contribute to enhanced flexibility in design. With programmable features, manufacturers can switch between different sewing patterns and styles with ease. This flexibility enables businesses to adapt to changing consumer preferences and experiment with innovative designs without investing in new machinery or extensive retraining of staff. As a result, companies can stay competitive and cater to niche markets more effectively.

Additionally, the implementation of CNC stitching machines can lead to a more sustainable manufacturing process. By minimizing fabric waste and optimizing resource usage, these machines can significantly reduce the environmental footprint of textile production. Companies can adopt more eco-friendly practices, aligning with the growing consumer demand for sustainability in fashion.

Despite the numerous benefits, the transition to CNC stitching machines also presents challenges. The initial investment in such advanced technology can be substantial, and companies may face a learning curve when integrating these machines into their existing workflows. However, the long-term advantages—such as reduced labor costs and improved product quality—often outweigh these initial hurdles.

In conclusion, CNC stitching machines represent a significant leap forward in the textile manufacturing industry. Their ability to enhance precision, speed, and flexibility while promoting sustainability makes them an invaluable asset to modern production processes. As technology continues to evolve, it is likely that CNC machines will play an increasingly central role in shaping the future of fashion and textiles, enabling manufacturers to innovate and thrive in an ever-changing market landscape.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025