cnc sewing machine

The Evolution and Impact of CNC Sewing Machines in Modern Textile Manufacturing

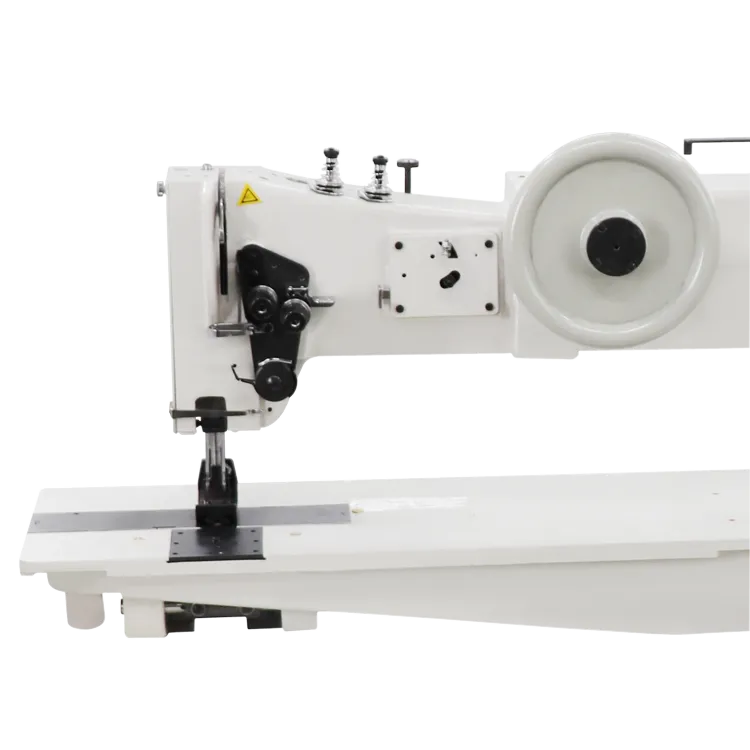

In the ever-evolving landscape of textile manufacturing, the introduction of Computer Numerical Control (CNC) technology has transformed traditional sewing practices into highly efficient and precise processes. CNC sewing machines, equipped with advanced software and robotics, have revolutionized the garment industry, allowing manufacturers to produce high-quality garments with remarkable speed and accuracy.

CNC sewing machines operate by using computer software to control the movement of the sewing machine’s needle and fabric. This technology enables intricate designs to be executed with laser-like precision, which is a significant departure from manual sewing methods. In the past, skilled artisans relied heavily on their craftsmanship and experience to create intricate patterns and designs. Today, CNC sewing machines can replicate these patterns consistently, reducing the dependency on human skills while maintaining a high standard of quality.

The Evolution and Impact of CNC Sewing Machines in Modern Textile Manufacturing

Moreover, the precision offered by CNC machines minimizes fabric waste. With the capability to calculate exact measurements and optimal cutting patterns, these machines ensure that every piece of fabric is utilized effectively. This not only contributes to cost savings for manufacturers but also aligns with sustainable practices, as reducing waste is critical in addressing environmental concerns related to the fashion industry.

cnc sewing machine

CNC sewing machines also offer increased versatility in design. With the ability to program complex patterns, manufacturers can easily experiment with various styles and techniques. This flexibility encourages creativity, leading to innovative designs that cater to diverse consumer preferences. Whether it’s simple embroidery or intricate patchwork, CNC technology allows for a breadth of design possibilities that were previously challenging to achieve.

Despite the advantages, the transition to CNC technology does pose some challenges. Initial investment costs for CNC machines can be high, which may deter smaller manufacturers from adopting this technology. Additionally, the shift from traditional sewing techniques requires training for staff, as workers must learn to operate and maintain these sophisticated machines. However, the long-term benefits, including increased efficiency and design capabilities, often outweigh the initial hurdles.

As the textile industry continues to evolve, the role of CNC sewing machines is likely to expand. Integration with artificial intelligence and machine learning could lead to further enhancements in predictive maintenance and design capabilities, ensuring that manufacturers can stay ahead of the competition. The rise of smart factories, where machines communicate and optimize processes autonomously, will also shape the future of garment manufacturing.

In conclusion, CNC sewing machines represent a significant advancement in the textile manufacturing process. By combining precision, efficiency, and design versatility, they have redefined the standards of production in the garment industry. Although challenges remain, the benefits of adopting CNC technology are undeniable, paving the way for a more innovative and sustainable future in fashion. As manufacturers embrace these tools, we can expect to see a transformation in the way garments are produced, setting new benchmarks for quality and efficiency in the industry.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025