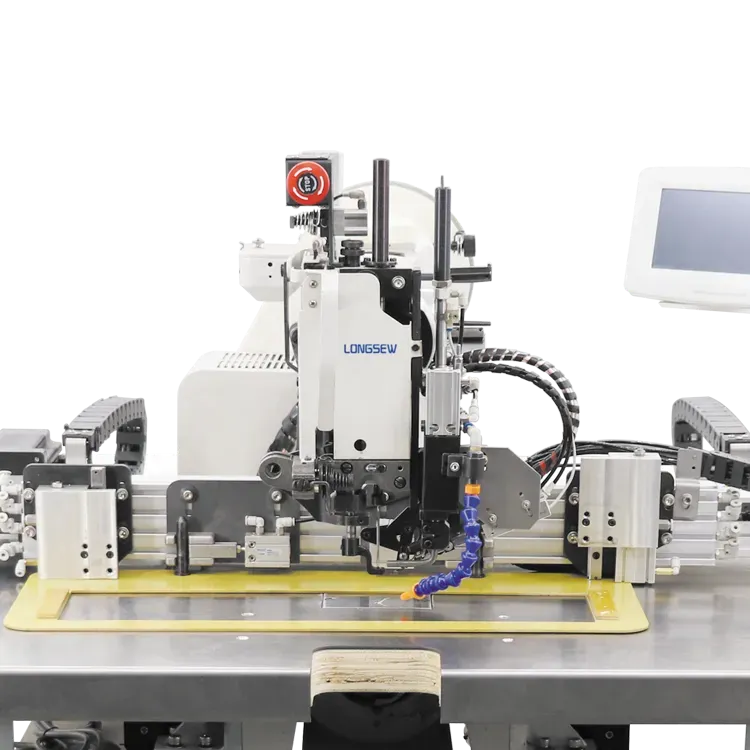

cnc pattern sewing machine

The Evolution and Advantages of CNC Pattern Sewing Machines

In the ever-evolving world of textile manufacturing, automation and precision play a pivotal role in enhancing productivity and ensuring high-quality outputs. Among the technological advancements that have significantly impacted this sector is the CNC (Computer Numerical Control) pattern sewing machine. This innovation combines the traditional art of sewing with state-of-the-art technology, bringing efficiency and precision to an industry that thrives on detail.

What is a CNC Pattern Sewing Machine?

A CNC pattern sewing machine is an automatic sewing machine that utilizes computer programming to control its operations. Unlike manual sewing machines, where operators guide the fabric and make decisions at each step, CNC machines follow pre-programmed patterns and designs with exceptional accuracy. This technology is particularly beneficial for manufacturers who need to produce large quantities of garments or textiles while maintaining consistency in design and quality.

The core of a CNC sewing machine lies in its software. Designers create patterns using specialized CAD (Computer-Aided Design) programs, which the CNC machine interprets to execute the sewing process. This allows for intricate designs that would be incredibly time-consuming and difficult to achieve by hand. The machine can handle various textile types, from delicate silks to heavy denims, making it versatile for different sewing applications.

The Advantages of CNC Pattern Sewing Machines

1. Precision and Accuracy One of the most significant advantages of CNC sewing machines is their ability to provide unmatched precision. The computer-controlled mechanism ensures that each stitch is placed exactly where it needs to be, eliminating the inconsistencies that can occur with manual sewing. This level of accuracy is essential for creating complex patterns, especially in high-end fashion and technical textiles, where even the slightest deviation can affect the final product.

cnc pattern sewing machine

2. Increased Productivity CNC pattern sewing machines vastly improve production speed. Once a pattern is programmed, the machine can run continuously, with little to no interruption. This capability means that manufacturers can increase their output significantly, meeting market demands more efficiently. Additionally, the automation of sewing processes reduces reliance on skilled labor, which can be particularly valuable in times of labor shortages.

3. Cost Efficiency While the initial investment in CNC machines can be substantial, the long-term savings are noteworthy. The ability to produce high volumes with reduced labor costs and minimal waste results in significant cost efficiencies. Furthermore, the accuracy of CNC machines minimizes fabric waste, as patterns can be optimized for material usage. This leads to a lower overall cost of production, providing a competitive edge in the marketplace.

4. Flexibility in Design With the power of digital design at their fingertips, manufacturers can easily modify patterns and designs to accommodate new trends or custom requests. This flexibility allows businesses to adapt quickly to consumer preferences, enabling faster turnaround times for new products. CNC machines can store multiple patterns, making it easy to switch between designs without the need for extensive setup time.

5. Enhanced Quality Control In an industry where quality is paramount, CNC sewing machines offer a reliable solution for maintaining high standards. The consistency in stitching not only enhances the aesthetic appeal of the final product but also contributes to its durability. This reliability builds customer trust and can lead to increased brand loyalty.

Conclusion

CNC pattern sewing machines represent a significant leap forward in the textile manufacturing process. By merging traditional sewing techniques with advanced technology, these machines ensure precision, boost productivity, and reduce costs. As the demand for high-quality, intricate designs continues to grow, the role of CNC machines in the manufacturing process will undoubtedly expand, solidifying their place as an indispensable tool in the modern textile industry. With their ability to adapt to various materials and designs, CNC machines not only enhance operational efficiency but also drive innovation, making them essential for businesses looking to thrive in a competitive market.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025