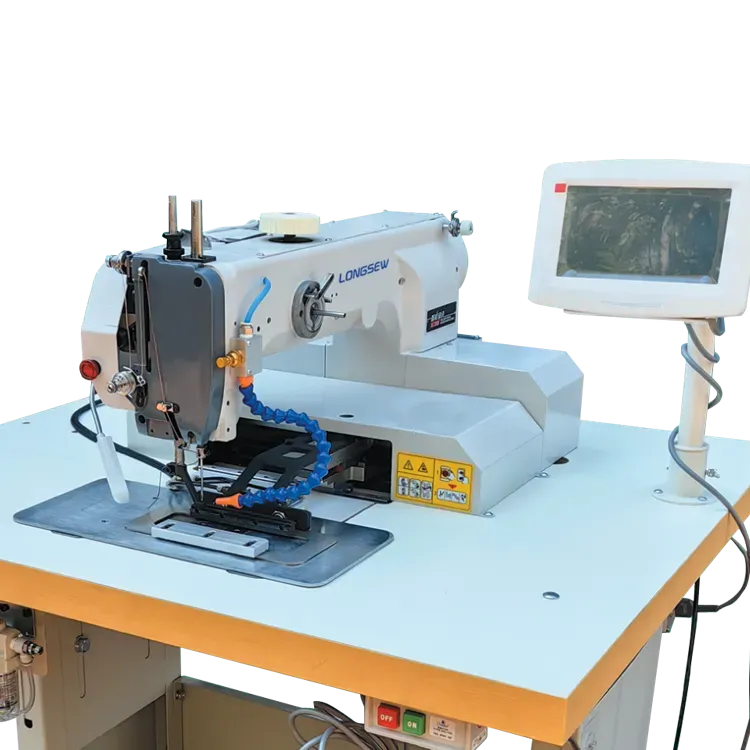

cnc machine silai

The Integration of CNC Machines in Modern Silk Printing

In the world of textile manufacturing, CNC (Computer Numerical Control) machines have revolutionized the way we approach silk printing. This technology allows for precision, efficiency, and versatility, which are essential characteristics in the competitive textile market. CNC machines have transformed traditional silk printing methods, enabling manufacturers to produce intricate designs with unrivaled accuracy.

The Integration of CNC Machines in Modern Silk Printing

One of the most significant advantages of using CNC machines in silk printing is the speed at which production can be accomplished. Traditional silk printing methods often require a considerable amount of time for setup and execution. With CNC technology, the setup is streamlined, and the printing process is fast-tracked. This efficiency not only increases production rates but also allows manufacturers to respond quickly to market demands. In an industry where trends can change overnight, the ability to produce quality silk fabrics in a timely manner gives companies a competitive edge.

cnc machine silai

Moreover, CNC machines provide the flexibility needed to experiment with different designs and materials. Silk printers can easily switch between projects without the need for extensive retooling. This adaptability allows designers to explore various styles, colors, and patterns, encouraging creativity and innovation in the silk printing process. By minimizing downtime and maximizing output, CNC machines enable textile companies to explore new market opportunities and diversify their product offerings.

Another aspect of CNC technology that benefits silk printing is the ability to use various printing techniques. Advanced CNC machines can integrate different printing methods, such as digital printing and screen printing, into one system. This multi-functional capability allows for greater design complexity, where artists can combine techniques to create unique, high-quality textile products. The versatility of CNC machines opens up new avenues for artistic expression in the realm of silk printing, making it possible to produce custom pieces that cater to niche markets.

Furthermore, CNC machines contribute to sustainability in silk printing. The precision offered by this technology reduces waste significantly compared to traditional printing methods. Materials are used more efficiently, and the need for excess fabric is diminished, leading to a lower environmental impact. As consumers become increasingly conscious of sustainability, manufacturers equipped with CNC technology can position themselves as eco-friendly alternatives in the marketplace.

In conclusion, the integration of CNC machines in the silk printing industry represents a significant leap forward in technology, efficiency, and creativity. With their precision, speed, and adaptability, CNC machines are reshaping the landscape of textile manufacturing, enabling companies to produce high-quality silk products that meet contemporary demands. As this technology continues to evolve, it will undoubtedly lead to even more innovative approaches in the art of silk printing. The future holds exciting possibilities for this intersection of craftsmanship and technology, ultimately benefiting manufacturers, designers, and consumers alike.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025