Jan . 20, 2025 12:59

Back to list

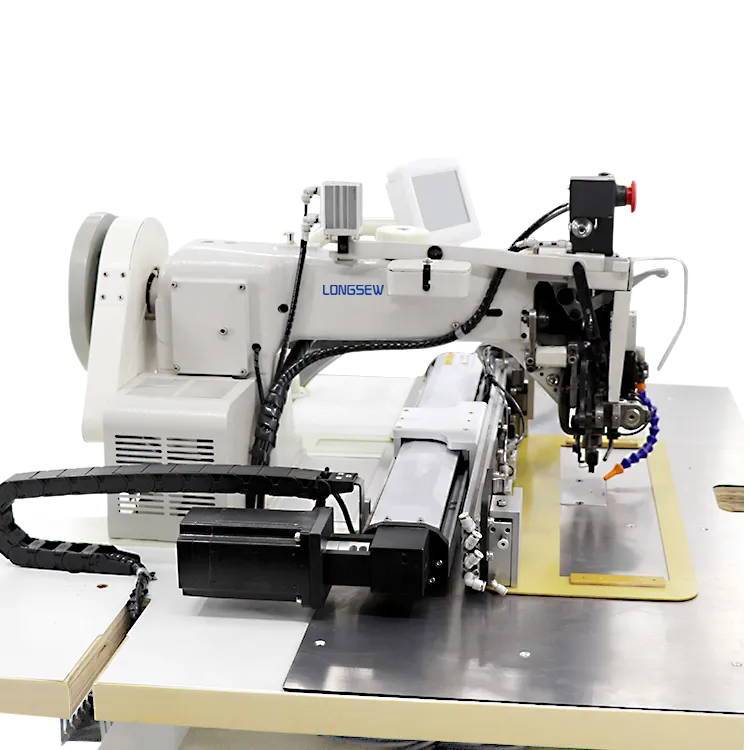

FIBC Bag / Jumbo Bag / Bulk Bag Single Needle Lock Stitch Top & Bottom Feeding Sewing Machine GSC367 /GSC367TD /GSC367TDZ/ GSC367-L

Changing a sewing machine needle might seem like a simple task, but it's vital for ensuring that your sewing projects are executed with precision and professionalism. As someone who has spent years honing expertise in sewing, I can attest that the needle is one of the most critical components of your machine. Let me guide you through the nuanced process of changing it, ensuring both optimal performance and the longevity of your sewing machine.

Insert your new needle with precision. The flat side generally faces the back, but always refer to your machine's manual for confirmation, as some models differ. Push the needle upwards into the needle clamp until it can go no further. Tighten the screw with care, ensuring the needle is securely in place without over-tightening, which can deform the needle’s shank or hinder future changes. Once the new needle is installed, run a test stitch on a scrap piece of fabric similar to your project material. This quality check verifies that the needle is correctly installed and prevents potential stitching issues during crucial project phases. A flawlessly performing machine instills confidence and allows you to focus on creativity and craftsmanship. Finally, note that the longevity and performance of your sewing machine heavily rely on routine maintenance beyond just needle changes. Consistent cleaning, timely oiling per the manufacturer's guidelines, and periodic professional servicing extend the life of your machine and keep it running smoothly for years. Ultimately, the seemingly small act of changing a sewing machine needle holds tremendous importance in the overall quality and efficiency of your sewing tasks. With experience and adherence to expert advice, this task becomes a seamless part of your sewing practice, contributing significantly to the professionalism and craftsmanship of your creations.

Insert your new needle with precision. The flat side generally faces the back, but always refer to your machine's manual for confirmation, as some models differ. Push the needle upwards into the needle clamp until it can go no further. Tighten the screw with care, ensuring the needle is securely in place without over-tightening, which can deform the needle’s shank or hinder future changes. Once the new needle is installed, run a test stitch on a scrap piece of fabric similar to your project material. This quality check verifies that the needle is correctly installed and prevents potential stitching issues during crucial project phases. A flawlessly performing machine instills confidence and allows you to focus on creativity and craftsmanship. Finally, note that the longevity and performance of your sewing machine heavily rely on routine maintenance beyond just needle changes. Consistent cleaning, timely oiling per the manufacturer's guidelines, and periodic professional servicing extend the life of your machine and keep it running smoothly for years. Ultimately, the seemingly small act of changing a sewing machine needle holds tremendous importance in the overall quality and efficiency of your sewing tasks. With experience and adherence to expert advice, this task becomes a seamless part of your sewing practice, contributing significantly to the professionalism and craftsmanship of your creations.

Previous:

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025