Exploring the Benefits of Chain Stitch and Coverstitch Machines for Sewing Projects

Understanding Chain Stitch and Coverstitch Machines in Sewing

In the realm of sewing and garment manufacturing, the chain stitch and coverstitch machines play a crucial role in enhancing the quality and durability of finished products. Both of these sewing techniques are essential for creating professional-looking seams and hems, making them indispensable tools in the industry. This article explores the intricacies, uses, and advantages of chain stitch and coverstitch machines.

Chain Stitch Machines

Chain stitch machines utilize a single thread looped around itself to create a series of interlocking stitches. The result is a stretchy and durable seam, which makes this type of stitching ideal for fabrics that require a bit more flex, such as knitwear and activewear.

1. Mechanism The mechanism behind a chain stitch is relatively simple. A needle thread is looped around a looper thread to form a continuous chain. This unique looping technique allows for elasticity and prevents the stitches from breaking easily, a critical feature for garments subjected to tension or movement.

2. Applications Chain stitches are commonly used in various applications, particularly in the construction of sportswear, loungewear, and some casual wear garments. They are particularly advantageous for sewing lightweight materials, as the chain stitch allows for less fabric bulk at the seams.

3. Advantages - Flexibility The chain stitch provides excellent stretch, making it perfect for garments that require significant movement. - Speed Chain stitch machines can sew at high speeds, increasing productivity in garment factories. - Cost-Effectiveness These machines have a lower thread consumption compared to traditional lockstitch machines, making them economical for large-scale production.

4. Disadvantages One of the main drawbacks of chain stitches is their susceptibility to unraveling if the seam is not secured properly. Additionally, they can sometimes produce a less finished appearance on the inside of the garment.

Coverstitch Machines

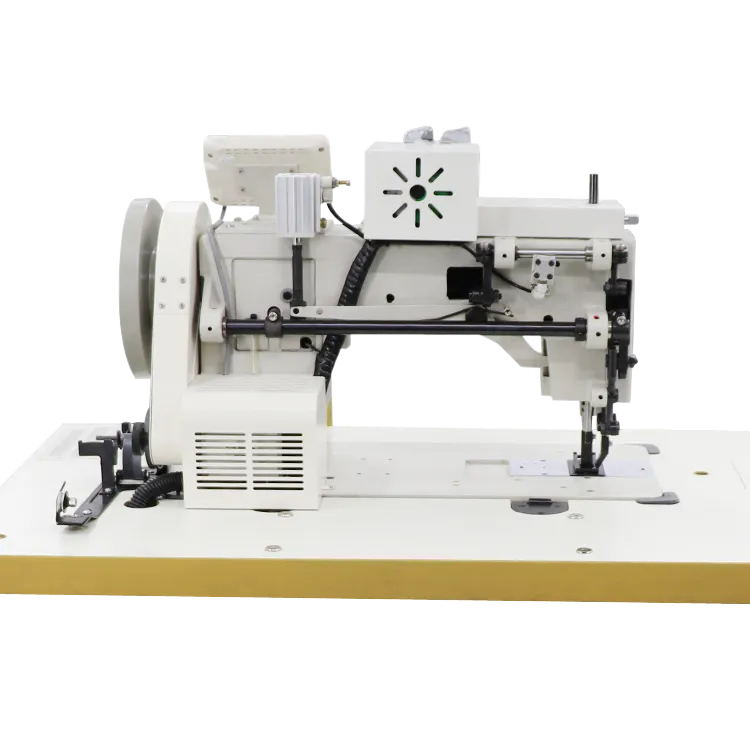

chain stitch coverstitch machine

Coverstitch machines, on the other hand, are designed to create a professional-looking finish on hems and seams

. Unlike chain stitch machines, coverstitch machines typically use multiple threads to provide a more robust and aesthetically pleasing seam.1. Mechanism A coverstitch machine can create two rows of straight stitching on one side of the fabric while forming a decorative, chain-like stitch on the opposite side. This simultaneous action allows for both strength and visual appeal.

2. Applications Coverstitch machines are predominantly used for hemming garments, especially in knit fabrics. They are popular in activewear, t-shirts, and other apparel that requires flat, stretchy hems.

3. Advantages - Professional Finish The coverstitch machine gives a neat, polished finish to hems, which enhances the overall appearance of the garment. - Durability The multiple threads used in coverstitching provide strong seams that can withstand significant wear and tear. - Flexibility Similar to chain stitches, coverstitching allows for the elasticity needed in knitwear.

4. Disadvantages One significant downside is that coverstitch machines can be more complex to operate and require more thread, which can slightly increase production costs. Moreover, they are not as versatile as other sewing machines and are primarily used for specific tasks.

Conclusion

In conclusion, both chain stitch and coverstitch machines are essential tools in the sewing industry, each offering unique benefits and applications. While chain stitch machines are favored for their speed and flexibility, coverstitch machines shine in providing clean, durable finishes. Understanding the roles of each can significantly impact the quality of a garment, and mastering these machines can elevate a seamstress's or manufacturer’s capability to create high-quality apparel. Whether one is creating high-performance sportswear or casual knit clothing, investing time in learning the nuances of these machines will undoubtedly lead to better craftsmanship and professional results.

By leveraging the strengths of chain stitch and coverstitch technologies, both amateur and professional sewers can improve their sewing techniques and produce garments that not only look great but also stand the test of time.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025