High-Quality Sewing Machines for Car Upholstery Projects

The Importance of Car Upholstery Sewing Machines in the Automotive Industry

In the ever-evolving world of the automotive industry, aesthetics and comfort play pivotal roles in a vehicle's appeal. One of the critical elements contributing to these factors is the quality of the car upholstery. This is where car upholstery sewing machines come into play, serving as an essential tool for manufacturers, restorers, and DIY enthusiasts alike.

Understanding Car Upholstery Sewing Machines

Car upholstery sewing machines are specially designed sewing machines tailored for automotive interior applications. Unlike standard sewing machines, which may struggle with thick, heavy fabrics, these specialized machines are constructed to handle multiple layers of durable materials such as leather, vinyl, and various synthetic textiles. They offer the power, precision, and versatility needed to produce high-quality upholstery that can endure the wear and tear associated with daily use.

The Evolution of Upholstery Techniques

Historically, car upholstery was primarily the domain of skilled artisans who used hand tools to sew materials. As technology progressed, the introduction of sewing machines revolutionized the process. The modern car upholstery sewing machine is typically equipped with features like adjustable stitch length, specialized presser feet, and sometimes even computer controls for more intricate designs. These advancements have made it easier to achieve a professional finish that meets the stringent quality demands of today's consumers.

Key Features That Matter

When selecting a car upholstery sewing machine, certain features are crucial. One of the most prominent factors is the machine’s ability to handle thick materials. Heavy-duty sewing machines with a high presser foot lift and a robust feed mechanism can tackle dense fabrics without skipping stitches or damaging the material.

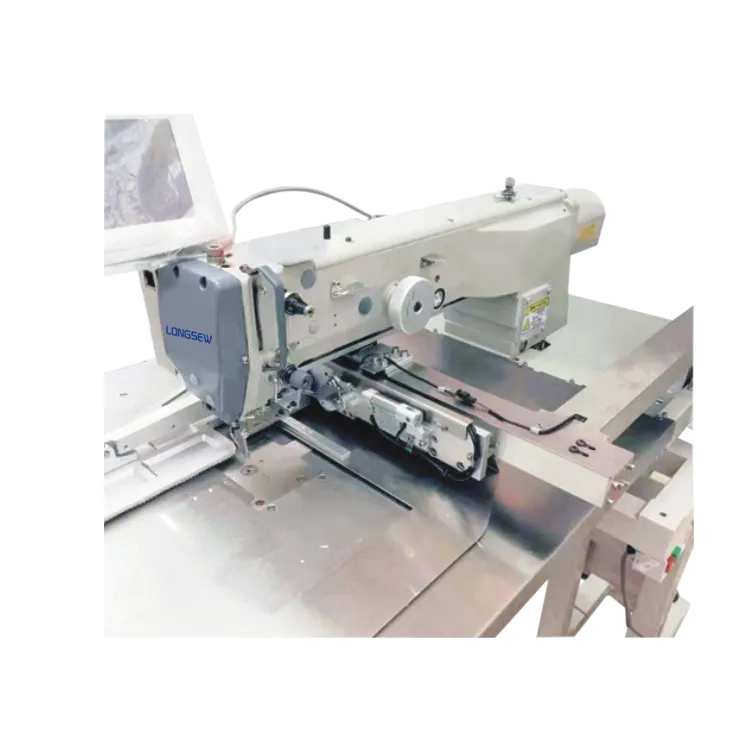

car upholstery sewing machine

Another important feature is the type of stitching the machine can perform. Many car upholstery tasks require various stitches, such as straight stitches, zigzag stitches, and decorative patterns. Machines that can switch between these types quickly provide versatility for different projects.

Motor power is also a critical consideration. A more powerful motor can sew through multiple layers of fabric with ease, which is particularly useful in automotive applications where durability is key. Additionally, features like a built-in walking foot and automatic needle positioning can greatly enhance efficiency and outcome.

Applications in the Industry

Car upholstery sewing machines are utilized across a broad spectrum of applications. In automotive manufacturing, these machines are integral in creating, repairing, and replacing seat covers, headliners, carpets, and interior door panels. By employing advanced sewing technology, manufacturers ensure that every component not only fits perfectly but also withstands the rigors of daily usage.

On the restoration side, classic car enthusiasts often seek authentic replacements for worn or damaged upholstery. Skilled professionals rely on high-quality sewing machines to craft pieces that resemble original materials and patterns, preserving the vehicle's heritage and value.

For DIY automotive projects, having a reliable upholstery sewing machine empowers hobbyists to take control of their customizations. Whether reupholstering a vintage car seat or adding personalized touches to a modern vehicle, these machines offer the tools necessary to bring creative visions to life.

Conclusion

In conclusion, car upholstery sewing machines are vital to the automotive industry, significantly impacting both the manufacturing and restoration processes. Their ability to handle heavy fabrics and provide quality stitching facilitates the creation of visually appealing and comfortable interiors that enhance a vehicle's overall experience. As technology continues to progress, we can anticipate even more groundbreaking developments in sewing machine design, further elevating the quality and longevity of automotive upholstery. For anyone interested in automotive craftsmanship, understanding the capabilities and features of car upholstery sewing machines is essential for achieving high standards of creativity and quality.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025