Choosing the Right Sewing Machine for Car Seat Upholstery Projects

The Importance of Sewing Machines in Car Seat Production

In the ever-evolving world of automotive manufacturing, the significance of specialized equipment cannot be overstated. Among these, the sewing machine tailored for car seat production plays a crucial role in ensuring quality, durability, and aesthetics. The car seat is not merely a functional component; it contributes significantly to the vehicle’s overall design, comfort, and safety, which makes the accuracy and efficiency of the sewing process imperative.

Specialized Sewing Machines

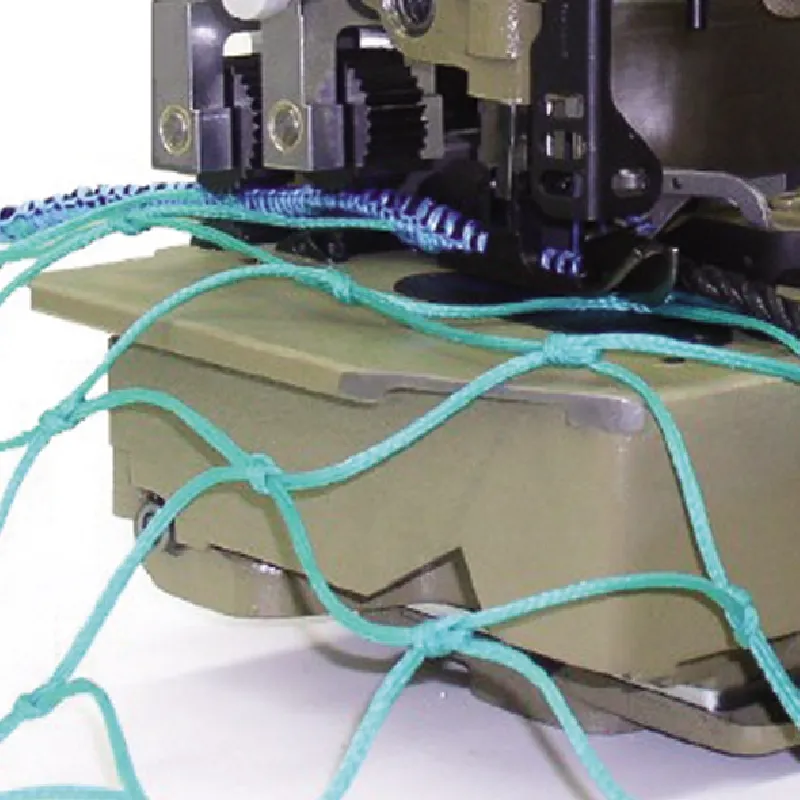

Car seat sewing machines are designed with specific features that cater to the unique requirements of automotive upholstery. Unlike conventional sewing machines, these specialized models are equipped to handle a variety of materials, including leather, synthetic fabrics, and foam. They can sew multiple layers of thick upholstery, ensuring that the seams are not only strong but also visually appealing.

One prominent feature of these machines is the heavy-duty motor that provides the necessary power to maneuver through dense materials. Additionally, they often come with advanced technologies such as automatic thread trimming and programmable stitching patterns, which enhance efficiency and reduce manual labor. The incorporation of computer-aided design (CAD) systems allows manufacturers to create intricate patterns and designs, ensuring that each car seat meets the specific aesthetic and functional requirements of different car models.

Quality Control and Safety

The stakes are high when it comes to car seat production, as these components are integral to passenger safety. Poorly constructed seats can lead to severe injuries in the event of an accident. Hence, car seat sewing machines often incorporate multiple quality control checks during the sewing process. High-speed stitching and consistent tension ensure that seams are tight and durable, while quality assurance inspections are integrated into the production line to catch any defects early.

car seat sewing machine

Furthermore, the materials used for car seats are subject to rigorous testing for flame resistance and wear, which is crucial for maintaining safety standards. Sewing machines designed for this purpose provide precision stitching that contributes to the overall integrity of the seat, ensuring that it can withstand not just daily use but also the stresses of potential accidents.

The Future of Car Seat Manufacturing

As technology continues to advance, the landscape of car seat manufacturing is set to evolve further. The integration of robotics and automation in sewing processes is on the rise, enabling faster production times while maintaining high-quality standards. Moreover, innovations in eco-friendly materials are challenging manufacturers to adapt their sewing techniques to accommodate new, sustainable fabrics.

The future of car seat sewing machines also lies in their adaptability. With the automotive industry shifting towards electric vehicles and smart technologies, the need for versatile sewing machines that can cater to different designs and materials will be more critical than ever.

Conclusion

In summary, the significance of sewing machines in car seat production extends far beyond mere stitching. These machines are vital components of a complex manufacturing process that prioritizes safety, quality, and aesthetic appeal. As technology continues to progress, the car seat sewing machine will undoubtedly remain a cornerstone of automotive manufacturing, ensuring that every ride is safe, comfortable, and stylish.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025