Sewing Machines for Car Seat Cover Production and Customization

The Essential Role of Stitching Machines in Car Seat Cover Manufacturing

The automotive industry is known for its innovation and relentless drive for quality. Among the myriad components that contribute to the overall comfort and aesthetic appeal of a vehicle, car seat covers stand out as both a practical necessity and a design element. The creation of these covers involves several intricate processes, one of which is the stitching process. At the heart of this process lies the car seat cover stitching machine, a vital tool in modern automotive manufacturing.

Understanding the Importance of Car Seat Covers

Car seat covers serve multiple purposes. They protect the seats from wear and tear, enhance the vehicle's interior aesthetics, and often provide added comfort. Given their importance, the quality of these covers is paramount. This is where the stitching machine plays a critical role.

Stitching machines are relied upon to create durable, precise, and aesthetically pleasing stitches. High-quality stitching not only ensures the longevity of the seat covers but also enhances their overall appearance. Manufacturers must consider various factors such as thread type, stitch pattern, and material compatibility, all of which can be efficiently managed by advanced stitching machines.

Types of Stitching Machines Used

There are several types of stitching machines employed in the production of car seat covers. Each type serves a unique purpose and is chosen based on the specific requirements of the cover being produced.

1. Industrial Sewing Machines These heavy-duty machines are designed for high-volume production and can handle thick materials. They are equipped to create various stitch types, providing flexibility in design.

2. Overlock Machines Often used for finishing edges, overlock machines ensure that fabric edges do not fray. This is especially important in car seat covers, where durability is critical.

3. Embroidery Machines For adding logos or intricate designs to seat covers, embroidery machines are essential. They can create detailed patterns that enhance the visual appeal of car interiors.

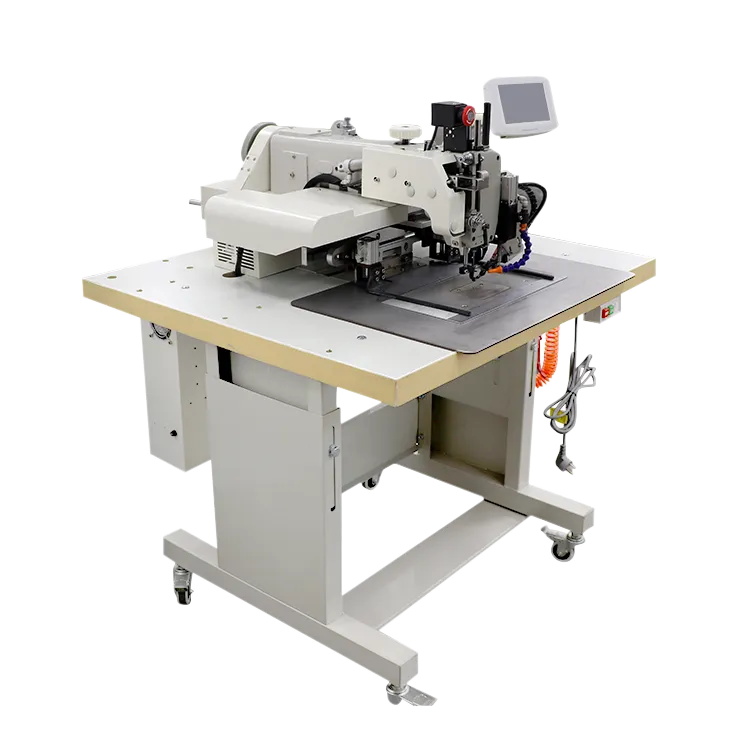

car seat cover stitching machine

4. Computerized Sewing Machines These advanced machines allow for precise control over sewing patterns. They can be programmed to create intricate designs and uniform stitches, ensuring high-quality production.

The Stitching Process

The stitching process in car seat cover production typically begins with the cutting of fabric to the required dimensions. Once the fabric pieces are prepared, they are fed into the stitching machine, where various patterns and techniques are employed.

Quality Control and Precision

Quality control is a crucial aspect of the stitching process. Manufacturers often implement strict guidelines to ensure that every stitch meets the high standards expected in the automotive industry. Automated stitching machines come equipped with sensors that detect inconsistencies, allowing for immediate adjustments.

Furthermore, the precision of modern stitching machines has improved significantly over the years. With advancements in technology, such as programmable settings and automatic threading systems, these machines can produce stitches with remarkable accuracy and speed. This efficiency not only reduces production time but also minimizes waste, making the process more sustainable.

Environmental Considerations

In today's world, environmental sustainability is a significant concern, even for the automotive industry. Many manufacturers are now opting for eco-friendly materials for car seat covers, which often require specialized stitching techniques. Advanced stitching machines can handle these new materials effectively, ensuring that production remains high-quality while adhering to environmentally friendly practices.

Conclusion

The car seat cover stitching machine is an indispensable asset in the automotive manufacturing process. These machines not only contribute to the efficiency of production but also ensure the quality and durability of the final product. As the automotive industry continues to evolve, so too will the technologies used in car seat cover manufacturing. By investing in advanced stitching machines, manufacturers can keep pace with changing consumer demands while delivering products that meet the highest standards of quality and sustainability. The intricate dance of fabric and thread, facilitated by these powerful machines, ultimately results in the comfortable and stylish car interiors that drivers and passengers alike appreciate.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025