Sewing Machine for Crafting Custom Car Floor Mats and Accessories

The Essential Role of Sewing Machines in Crafting Car Mats

When it comes to automaking, every detail matters, and one component that often goes unnoticed is the car mat. These mats play a crucial role in both maintaining the vehicle's cleanliness and enhancing its aesthetic appeal. The process of creating high-quality car mats is intricate, and at the core of this production lies a vital piece of equipment the sewing machine.

The Importance of Car Mats

Car mats serve several important functions. Firstly, they protect the vehicle’s flooring from dirt, mud, spills, and wear. This not only extends the lifespan of the vehicle's interior but also increases its resale value. Secondly, car mats contribute to the aesthetic quality of the vehicle, available in various colors, patterns, and materials to match the owner’s preferences. Whether one desires luxurious carpet mats or durable rubber ones, the options are extensive.

Given their importance, the manufacturing of car mats demands precision and quality. This is where sewing machines come into play.

Types of Sewing Machines for Car Mats

When it comes to sewing car mats, specific types of sewing machines are utilized to achieve the best results. Industrial sewing machines are typically preferred for mass production due to their speed and durability. They are capable of handling thick materials such as carpets and rubber, which are commonly used in car mats. Heavy-duty sewing machines equipped with walking feet are particularly sought after, as they can move multiple layers of fabric smoothly without slipping.

Additionally, computerized sewing machines are increasingly being integrated into the manufacturing process. These machines allow for precision in stitching patterns and designs, ensuring a uniform finish. Automation has revolutionized the way car mats are produced, allowing for quicker outputs and reduced labor costs while maintaining high quality.

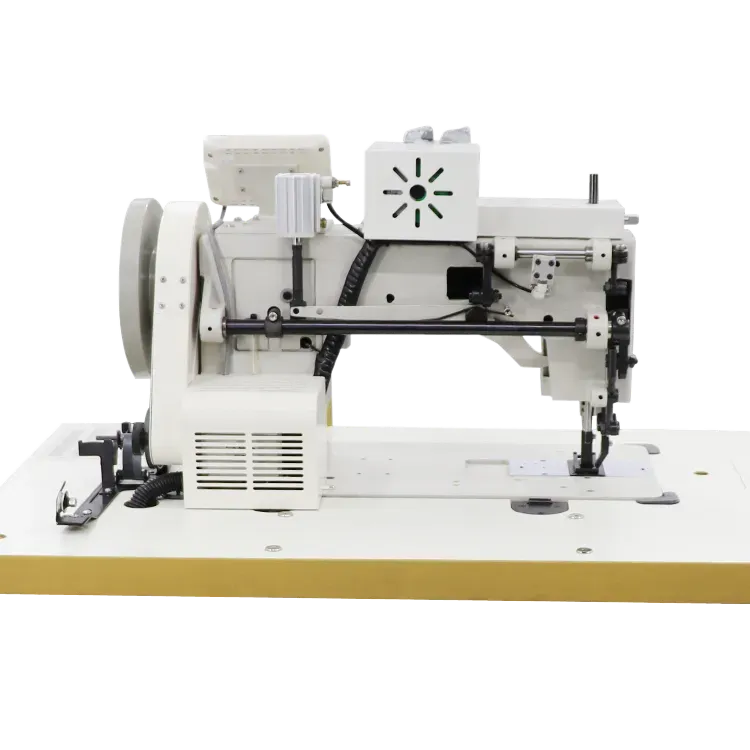

car mats sewing machine

The Sewing Process

The sewing process for car mats involves several steps. Initially, the selected materials are cut into the desired shapes and sizes. This requires precision tools and templates to ensure consistency across the production line. Following this, the sewing machines come into action. The edges of the mats are often hemmed or bound to prevent fraying, and custom designs may be stitched onto the surface.

Quality control is paramount during this phase. Each car mat is inspected for defects, ensuring that only the best products reach consumers. A superior car mat is one that not only fits perfectly but also holds up against everyday wear and tear.

Innovations in Sewing Technology

As technology continues to advance, so does the equipment used for creating car mats. Innovations in sewing technology have introduced features such as programmable sewing patterns, which reduce the need for manual adjustments and enhance efficiency. Moreover, environmentally friendly materials are gaining traction, and sewing machines are now able to accommodate these sustainable options, aligning with the automotive industry’s growing focus on eco-friendliness.

Conclusion

In conclusion, sewing machines are an indispensable part of the car mat manufacturing process. They not only ensure the efficiency and quality of production but also allow for creative designs that can personalize a vehicle's interior. As the automotive industry continues to evolve, so too will the technology behind sewing machines, leading to even more advanced methods of creating car mats that are both functional and stylish. Whether for luxury vehicles or everyday cars, the humble car mat deserves recognition, given the craftsmanship that goes into producing it – a testament to the capabilities of modern sewing machines.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025