Jan . 14, 2025 15:19

Back to list

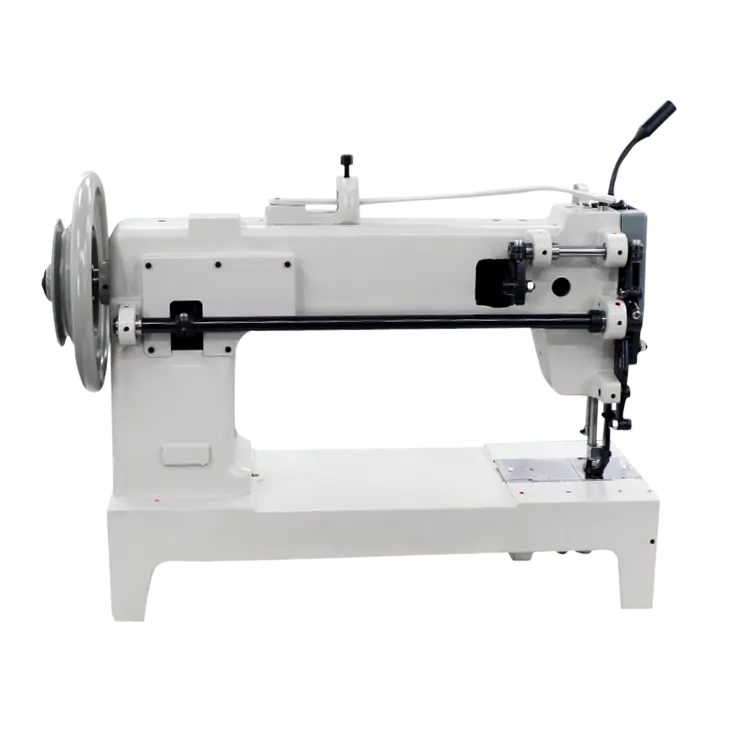

FIBC Bag / Jumbo Bag / Bulk Bag Single Needle Lock Stitch Top & Bottom Feeding Sewing Machine GSC367 /GSC367TD /GSC367TDZ/ GSC367-L

Bobbinless lockstitch sewing machines are paving the way for a revolution in the textile industry, redefining efficiency and precision in garment production. Users no longer have to grapple with the frequent interruptions caused by empty bobbins. Instead, these innovative machines use a continuous thread system, which seamlessly delivers consistent quality and output.

Authoritativeness in understanding textile machinery extends to recognizing the cutting-edge brands utilizing bobbinless technology. Brands like Juki and Brother have made strides in this arena, backing their models with extensive research and development. Their machines not only carry performance guarantees but often include comprehensive training programs catered to operational excellence. Manufacturers sourcing these technologies gain the leverage of experience from these pioneering brands, equipping them with reliable tools to outshine competitors. Trustworthiness in bobbinless machines also comes from sustainability considerations. As brands worldwide aim to reduce waste, these machines contribute favorably by eliminating leftover bobbin spools. By minimizing the material discarded during production, companies can align their operations with eco-friendly practices, appealing to the growing market of environmentally conscious consumers. In conclusion, the adoption of bobbinless lockstitch sewing machines is a vital strategic move for any forward-thinking garment manufacturer. With direct experience and professional expertise, I've seen firsthand the increased efficiency and quality these machines bring to production lines, backed by authoritative brands offering trustworthy and sustainable solutions. As the textile industry constantly evolves, embracing such innovation proves indispensable for maintaining competitive advantage and fostering growth.

Authoritativeness in understanding textile machinery extends to recognizing the cutting-edge brands utilizing bobbinless technology. Brands like Juki and Brother have made strides in this arena, backing their models with extensive research and development. Their machines not only carry performance guarantees but often include comprehensive training programs catered to operational excellence. Manufacturers sourcing these technologies gain the leverage of experience from these pioneering brands, equipping them with reliable tools to outshine competitors. Trustworthiness in bobbinless machines also comes from sustainability considerations. As brands worldwide aim to reduce waste, these machines contribute favorably by eliminating leftover bobbin spools. By minimizing the material discarded during production, companies can align their operations with eco-friendly practices, appealing to the growing market of environmentally conscious consumers. In conclusion, the adoption of bobbinless lockstitch sewing machines is a vital strategic move for any forward-thinking garment manufacturer. With direct experience and professional expertise, I've seen firsthand the increased efficiency and quality these machines bring to production lines, backed by authoritative brands offering trustworthy and sustainable solutions. As the textile industry constantly evolves, embracing such innovation proves indispensable for maintaining competitive advantage and fostering growth.

Latest news

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025