Creating Binding Belts for Seamless Sewing Projects and Crafting Techniques

The Importance and Applications of Binding Belt Sew Techniques in Textile Industries

Binding belt sew techniques play a crucial role in the textile industry, providing not only functionality but also aesthetic appeal to various fabric products. This method, which involves sewing a binding strip over the edges of the fabric, is widely employed in creating durable, finished hems for a variety of applications, from garments to accessories and industrial textiles.

One of the primary advantages of using binding belt sewing is its ability to reinforce edges that are prone to fraying. Many fabrics, particularly those made from natural fibers, can easily unravel when cut. Binding the edges securely prevents this deterioration and extends the lifespan of the product. This is particularly important in items such as garments and bags, where frayed edges can lead to structural failure and an unkempt appearance. The binding serves as a protective layer, ensuring that the fabric remains intact even after repeated use and washing.

In addition to reinforcing edges, binding belt sewing allows for creative expression through the use of various width patterns and colors. Designers can choose binding materials that complement or contrast with the main fabric, enhancing the overall visual impact of the product. For instance, a vibrant binding can add a pop of color to a neutral-colored fabric, while a subtle tone can create an elegant finish. This versatility makes binding belt sewing an essential technique in fashion design and home decor.

The application of binding belt sew techniques extends beyond aesthetics. In industrial settings, binding is crucial for producing items such as upholstery, tents, and tarpaulins. These applications demand robust stitching that can withstand harsh conditions. The binding not only strengthens the seams but also provides additional waterproofing when appropriate materials are used. In this context, binding belt sew ensures that products are not only visually appealing but also designed for performance and durability.

binding belt sew

Furthermore, binding techniques can be employed in various ways to suit different fabric types and project requirements. For example, bias binding, which is made from strips of fabric cut on the bias, is particularly popular for curves and corners, allowing a smooth and professional finish. Folded or double-folded binding is used widely for straight edges, providing a neater appearance and additional layer of protection. Each method caters to specific needs within the sewing process, highlighting the versatility of binding techniques in the industry.

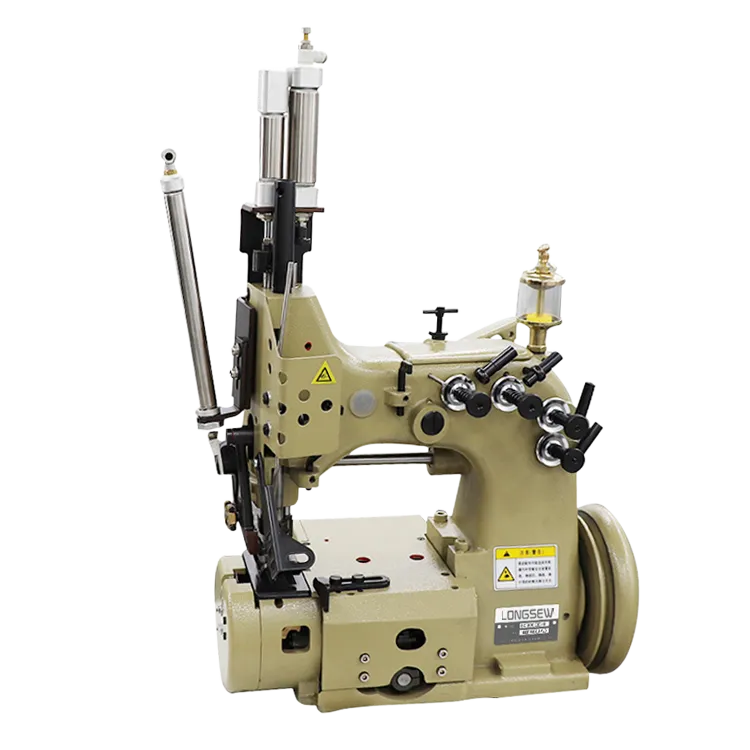

As technology continues to advance, the methods and machinery used for binding belt sew are also evolving. Innovative sewing machines equipped with specialized binding attachments simplify the process, allowing manufacturers to produce high-quality products in a shorter time frame. Automation in the sewing process not only enhances efficiency but also ensures remarkable consistency in the finished products. With these advancements, the textile industry can meet the increasing demand for fast fashion while maintaining high standards of quality.

However, despite the technological developments, the artistry of binding belt sewing remains rooted in traditional craftsmanship. Skilled tailors and seamstresses understand the nuances of fabric behavior and the intricacies of different binding techniques, enabling them to execute their work with precision. This blend of art and technology allows for a wide range of products that appeal to consumers on multiple levels.

In conclusion, binding belt sew techniques are indispensable in the textile industry, blending functionality with creativity. Whether in garments, home textiles, or industrial products, binding plays a vital role in enhancing the durability and aesthetic of fabric items. As the industry embraces both traditional craftsmanship and modern technology, the future of binding techniques promises to be as dynamic as the fabrics they adorn.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025