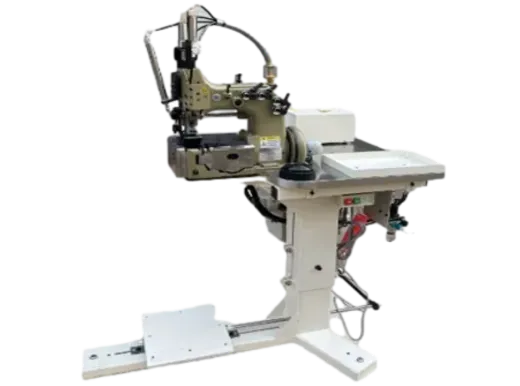

Big Bag Baffle Sewing Machine for Efficient and Creative Fabric Projects

The Big Bag Baffle Sewing Machine Revolutionizing Textile Production

In the ever-evolving world of textile production, machinery plays a crucial role in enhancing efficiency and quality. Among the array of available machines, the Big Bag Baffle Sewing Machine has emerged as a notable innovation tailored specifically for the production of large bags, particularly those used in industrial applications. This machine not only streamlines the sewing process but also improves the durability and functionality of the end products.

Understanding the Big Bag Baffle Sewing Machine

At its core, the Big Bag Baffle Sewing Machine is designed to create baffles within large bags, a feature that is essential for the stabilization of the bag's contents. Baffles are internal partitions that help maintain the bag’s shape while also preventing the cargo from shifting during transport. This is especially important for bulk materials such as grains, fertilizers, and chemicals, which can be challenging to handle without proper containment.

The machine’s design incorporates advanced technology, enabling it to sew heavy-duty fabrics with precision. Typically equipped with walking feet, it ensures that multiple layers of thick material are fed evenly through the machine, reducing the chances of slippage and misalignment. This is a significant improvement over traditional sewing methods, which can struggle with the weight and thickness of the materials used in large bag production.

Features and Benefits

1. Efficiency The Big Bag Baffle Sewing Machine is engineered for high-speed operation. Unlike manual sewing methods or less specialized machines, it can produce large volumes of bags in a shorter time frame. This increased efficiency translates to higher production rates, making it a game-changer in industrial sewing applications.

2. Versatility This machine is capable of handling various types of materials, including polypropylene, polyethylene, and woven fabrics. Its versatility allows manufacturers to adapt to different product needs without the necessity for multiple machines.

big bag baffle sewing machine

3. Durability Bags produced with the Big Bag Baffle Sewing Machine exhibit greater durability due to the precision of the baffle design. The machine ensures that seams are strong and secure, which is vital for bags that may experience rough handling or extreme conditions during transport and storage.

4. Ease of Use Modern designs of the Big Bag Baffle Sewing Machine incorporate user-friendly interfaces, making it easier for operators to set up and adjust settings for different sewing jobs. With automated features, such as tension control and stitch length adjustments, even operators with minimal experience can achieve high-quality results.

5. Cost-Effectiveness By reducing the time and labor involved in bag production, this machine increases overall productivity. The initial investment may be substantial, but the long-term savings in labor and increased output make it a wise choice for manufacturers.

Applications in Various Industries

The Big Bag Baffle Sewing Machine has a wide range of applications across various industries. In agriculture, these machines are indispensable for producing bags for storing grains and feed. The chemical industry also benefits significantly, as safe and secure packaging is vital for transporting hazardous materials. Furthermore, in construction, such bags are used for aggregates and other bulk materials.

Moreover, with the growing emphasis on environmental sustainability, the textile industry is witnessing a shift towards eco-friendly materials. The Big Bag Baffle Sewing Machine is versatile enough to accommodate biodegradable fabrics, allowing manufacturers to stay ahead in an increasingly environmentally conscious market.

Conclusion

In conclusion, the Big Bag Baffle Sewing Machine is a pivotal advancement in textile production. By enhancing efficiency, durability, and versatility, it meets the complex demands of modern industry. As manufacturers continue to seek innovative solutions to improve productivity and sustainability, this cutting-edge machine is poised to play an essential role in shaping the future of textile manufacturing. With its ability to adapt to various materials and improve the quality of large bags, the Big Bag Baffle Sewing Machine indeed represents a significant leap forward in the realms of industrial sewing. Embracing this technology not only propels manufacturers into a new era of production but also ensures that they remain competitive in an ever-changing marketplace.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025