bag seaming machine

The Importance of Bag Seaming Machines in Modern Manufacturing

In the rapidly evolving landscape of manufacturing and packaging, efficiency and precision have become paramount. One of the pivotal technologies that have emerged to meet these demands is the bag seaming machine. This specialized equipment plays a critical role in the packaging industry, ensuring that products are securely sealed and presented in a manner that is both attractive and functional.

Understanding Bag Seaming Machines

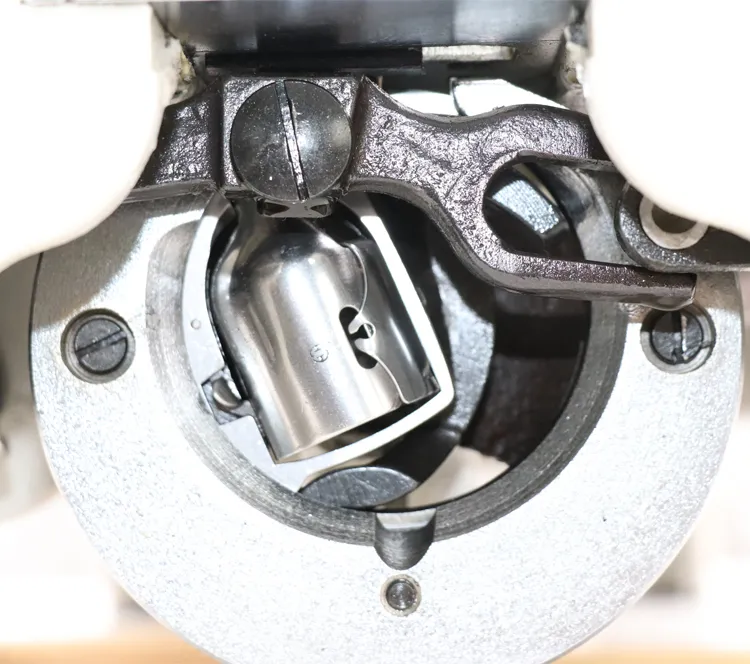

Bag seaming machines are designed to join the edges of bags, typically made from various materials such as plastic, paper, and woven fabrics. These machines employ a range of sealing techniques, including heat sealing, stitching, and ultrasonic sealing, to create durable and reliable seams. The choice of sealing method often depends on the type of bag material and the intended application, making it essential for manufacturers to select the right machine for their needs.

Types of Bag Seaming Machines

There are several types of bag seaming machines, each tailored for specific applications. Some of the most common types include

1. Heat Sealers These machines use heat to melt the edges of the bag material together, forming a strong bond. They are widely used for plastic and polyethylene bags.

2. Sewing Machines These machines stitch the edges of the bags together using durable threads, often employed in the production of fabric or paper bags.

3. Ultrasonic Sealing Machines Utilizing high-frequency sound waves, these machines create friction that heats and fuses the bag material. This method is particularly effective for thin materials and offers a fast and efficient sealing process.

4. Automatic Baggers Combining bag sealing with automation, these machines can efficiently produce and seal bags in high volumes, significantly reducing labor costs and enhancing productivity.

Benefits of Using Bag Seaming Machines

The advantages of implementing bag seaming machines in manufacturing processes are manifold

bag seaming machine

- Increased Efficiency Automated bag seaming machines operate at high speeds and can produce a large number of sealed bags in a short period, thereby increasing overall production efficiency

.- Consistency in Quality With automated machines, manufacturers can achieve consistent seam quality across all bags, reducing the chances of defects and returns.

- Cost-Effectiveness Investing in a bag seaming machine can lead to significant cost savings in the long run. By streamlining the packaging process, businesses can reduce labor costs and minimize material waste.

- Versatility Modern bag seaming machines are designed to handle a variety of materials and bag styles, allowing manufacturers to diversify their product offerings without extensive equipment changes.

Applications of Bag Seaming Machines

Bag seaming machines are utilized across numerous industries, highlighting their versatility and importance. Some of the key sectors that benefit from these machines include

- Food Packaging Ensuring the freshness and safety of food products is crucial. Bag seaming machines provide airtight seals that help preserve the integrity of perishable items.

- Pharmaceuticals In the pharmaceutical industry, where contamination can lead to serious health risks, bag seaming machines play a vital role in packaging medicines securely.

- Construction For bagged materials like cement and sand, strong seams are essential to prevent spillage during transportation and handling.

- Retail Custom-printed bags for retail purposes often require specialized sealing techniques to maintain their aesthetic appeal while ensuring durability.

Conclusion

As the manufacturing and packaging sectors continue to advance, bag seaming machines will remain a fundamental component of efficient production lines. Their ability to provide reliable, high-quality seals not only enhances product integrity but also elevates brand reputation through professional packaging. Investing in the right bag seaming machine is crucial for manufacturers aiming to optimize their operations and stay competitive in a fast-paced market. Embracing this technology is not just about improved efficiency; it's about ensuring that products reach consumers in the best possible condition, contributing to overall customer satisfaction and business success.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025