Sewing Machine Techniques for Perfecting Bag Closures and Finishing Touches

The Evolution of the Bags Closer Sewing Machine

In the world of manufacturing and textile production, the bags closer sewing machine is a crucial piece of equipment that has revolutionized the way bags are sealed, whether for packaging or fashion purposes. This machine is designed specifically to stitch the open ends of bags, ensuring they are sealed securely to protect their contents. Over the years, these machines have evolved significantly, incorporating advanced technology to enhance efficiency and streamline the production process.

Historical Background

The origins of the bags closer sewing machine can be traced back to the early 20th century when mass production began to take hold in various industries. Initially, bag closing was done manually, which was time-consuming and required substantial labor. As the demand for packaged products grew, manufacturers sought a solution to speed up the process and reduce labor costs. This led to the development of the first sewing machines specifically designed to close bags.

Functionality and Features

Today’s bags closer sewing machines come equipped with several features that make them versatile and user-friendly. They typically use heavy-duty threads to ensure strong seams, capable of withstanding the rigors of transportation and handling. Most machines are outfitted with adjustable stitch lengths, allowing operators to switch between different types of bags and materials with ease.

Moreover, modern machines have adapted to include automatic functions that boost productivity. Features such as automatic needle positioning, programmable sewing patterns, and even built-in safety mechanisms are now standard. Operators can work more efficiently, focusing on quality control rather than the mechanical intricacies of sewing.

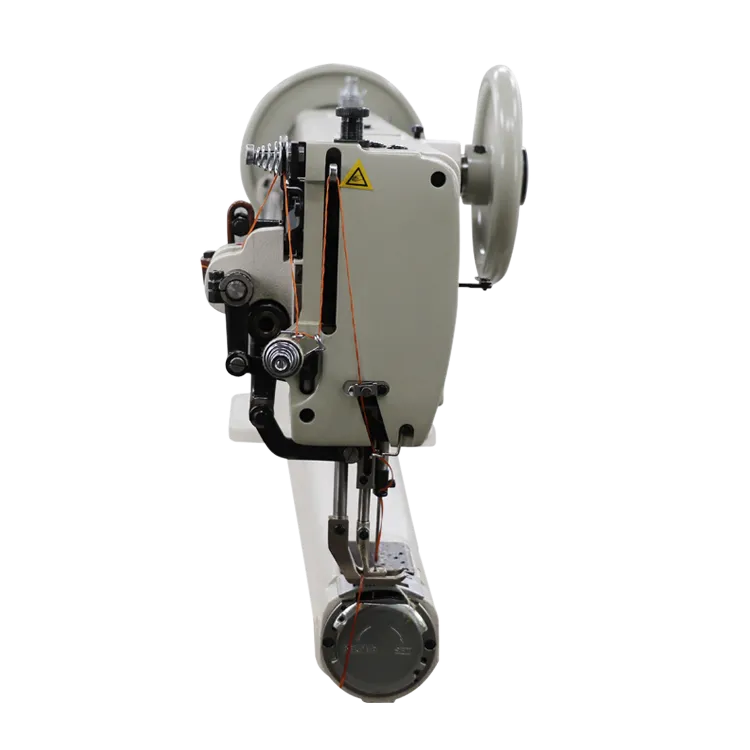

bags closer sewing machine

Types of Bags Closer Sewing Machines

There are several types of bags closer sewing machines tailored to different industrial needs. For instance, there are portable models that can be easily transported for onsite bag sealing, especially in agricultural settings. On the other hand, industrial-grade machines are built for high-volume production lines, capable of stitching hundreds of bags per hour.

Additionally, specialized machines are designed for specific kinds of bags, such as woven polypropylene, paper, or burlap. Each type of bag presents unique challenges, and manufacturers have responded by creating machines that cater specifically to these materials, ensuring durability and reliability.

Environmental Considerations

As industries become more conscious of their environmental impacts, manufacturers of bags closer sewing machines are also focusing on sustainability. New models are designed to use eco-friendly materials and energy-efficient components without sacrificing performance. Some companies are even exploring innovations in reducing waste generated during the bag sealing process.

Conclusion

The bags closer sewing machine is a testament to the ingenuity of the textile industry. From its manual origins to the sophisticated, automated machines we see today, it has played an essential role in transforming how products are packaged and transported. As technology continues to advance, we can expect further improvements in both the efficiency and sustainability of these machines, continuing to change the landscape of manufacturing and textile production. In an age where speed and reliability are paramount, the bags closer sewing machine remains an indispensable tool for businesses worldwide.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025