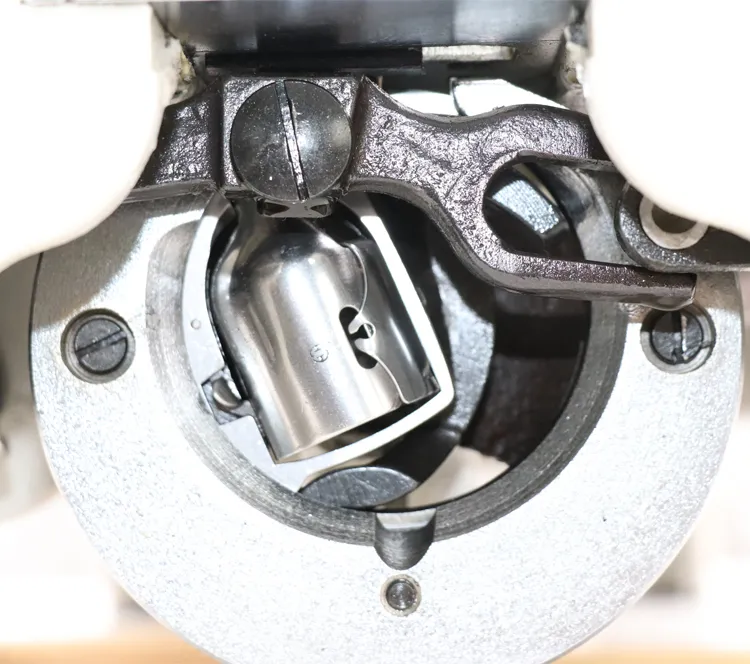

bag closing sewing machine head

The Importance of Bag Closing Sewing Machines in Modern Manufacturing

In today’s fast-paced manufacturing environment, efficiency and quality are paramount. One crucial piece of equipment that has significantly contributed to these aspects is the bag closing sewing machine. These machines are specifically designed for sealing different types of bags, including those made from textiles, plastics, and multi-layer materials. Their functionality has evolved over the years, making them indispensable in industries ranging from packaging to food production.

Bag closing sewing machines are engineered to handle a variety of bag types, ensuring that products remain secure during storage and transportation. With the increased demand for packaged goods, the role of these machines has expanded. They are now used to close everything from agricultural sacks to pet food bags, and even heavy-duty industrial bags. Their versatility makes them essential tools in any production line.

The Importance of Bag Closing Sewing Machines in Modern Manufacturing

Moreover, quality assurance is critical in packaging. A poorly closed bag can lead to product spoilage, customer complaints, and increased return rates. Bag closing sewing machines are designed to deliver consistent stitch quality, which is essential for maintaining the integrity of the sealed bag. Many models incorporate features like tension control and stitch length adjustment, ensuring a uniform seal that withstands various handling and environmental conditions.

bag closing sewing machine head

In addition to efficiency and quality, bag closing sewing machines also offer significant cost savings. Automating the bag closing process reduces labor costs and minimizes the risk of human error. As businesses strive to increase profit margins, investing in reliable bag closing equipment becomes a strategic move. Furthermore, these machines are often built with durability in mind, requiring less frequent maintenance and replacement, which further enhances their cost-effectiveness.

Sustainability has also become an important factor in manufacturing today. As industries seek to reduce their environmental footprint, many bag closing machines are designed to work with eco-friendly materials. Manufacturers are increasingly producing biodegradable and recyclable bags that these machines can efficiently seal. This shift not only meets consumer demands for sustainable products but also aligns with global efforts to reduce plastic waste.

As we look to the future, the evolution of bag closing sewing machines will likely continue, driven by advancements in technology and changing market needs. The integration of smart features, such as real-time monitoring and predictive maintenance, could revolutionize the way these machines operate. Such innovations would provide manufacturers with deeper insights into their production processes, allowing for even greater efficiency and reliability.

In conclusion, bag closing sewing machines play a pivotal role in modern manufacturing across various industries. Their speed, efficiency, and reliability directly impact the quality of packaged goods, making them essential investments for businesses aiming to thrive in a competitive marketplace. As industries advance, the demand for high-quality bag closing solutions will undoubtedly continue to grow, reinforcing the significance of these machines in the manufacturing landscape.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025