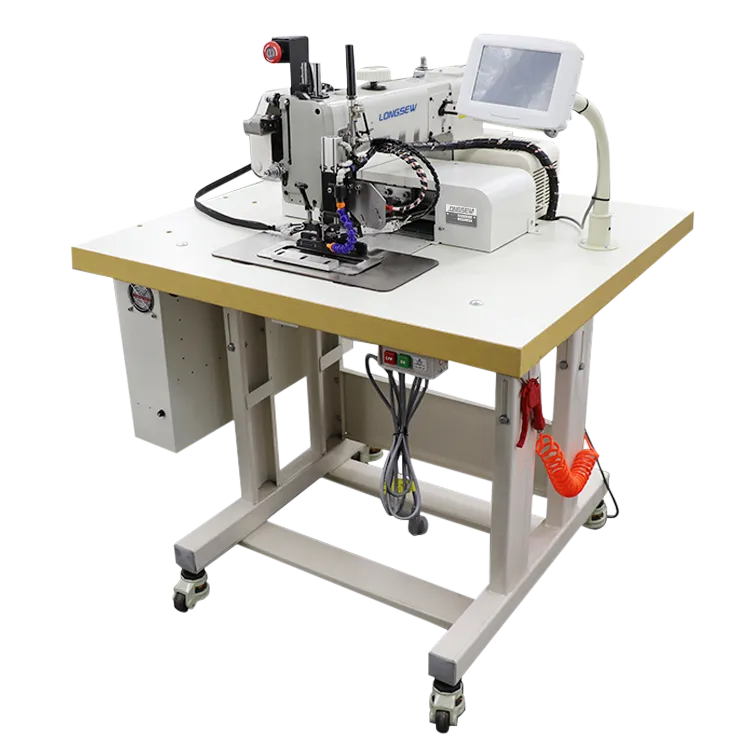

bag closing machine

The Evolution and Importance of Bag Closing Machines

Bag closing machines play a pivotal role in various industries, contributing significantly to the efficiency and productivity of packaging processes. From agriculture to food production, and from pharmaceuticals to textiles, these machines ensure that products are securely sealed in bags, preserving their freshness and safety during storage and transportation.

The modern bag closing machine has come a long way since its inception. Early bag sealing methods were labor-intensive, relying heavily on manual labor. Workers would seal bags using stitching or adhesive substances, which often led to inconsistent quality and durability. However, the introduction of bag closing machines revolutionized this process, making it faster, more reliable, and cost-effective.

One of the most significant advancements in bag closing technology is the development of automated bag closing machines. These machines are designed to handle high volumes of bags, making them ideal for large-scale operations. With features such as adjustable speed settings and programmable closure types, companies can customize the sealing process to meet their specific needs. This adaptability is crucial in today’s fast-paced production environments, where efficiency and precision are paramount.

Bag closing machines use various methods to seal bags, including stitching, heat sealing, and adhesive application. Stitching machines typically use heavy-duty threads to create a secure closure, suitable for bags containing grains, animal feed, or other bulk materials. On the other hand, heat sealing machines employ high temperatures to bond the edges of plastic bags, providing an airtight seal that is especially important for perishable goods like food.

bag closing machine

The implementation of bag closing machines also has a direct impact on product safety. A well-sealed bag reduces the risk of contamination, spoilage, and pest intrusion. For sectors like food and pharmaceuticals, where hygiene is of utmost importance, using advanced bag closing technology ensures that products remain uncontaminated until they reach the consumer. This layer of protection not only supports public health but also enhances brand reputation by ensuring that companies can deliver quality products.

In addition to safety and efficiency, bag closing machines contribute to sustainability efforts. Many manufacturers are now introducing machines that support eco-friendly practices by enabling the use of recyclable materials. By facilitating the use of biodegradable bag options and reducing excess material usage, these machines help companies minimize their environmental footprint.

Maintenance and serviceability of bag closing machines are crucial factors to consider for businesses looking to invest in this technology. Regular maintenance ensures that the machines operate smoothly and efficiently, reducing downtime and operational costs. Many manufacturers provide training and support for maintenance, allowing businesses to troubleshoot common issues and perform routine check-ups effectively.

In conclusion, bag closing machines have transformed the packaging landscape across various industries. Their ability to enhance efficiency, ensure product safety, and support sustainability makes them an indispensable part of modern production lines. As technology continues to advance, we can expect even more innovative features and improvements in bag closing machines, further optimizing packaging processes and reinforcing their vital role in global commerce. Investing in these machines is not just a matter of operational efficiency; it is an essential step towards ensuring quality, safety, and sustainability in an increasingly competitive market.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025