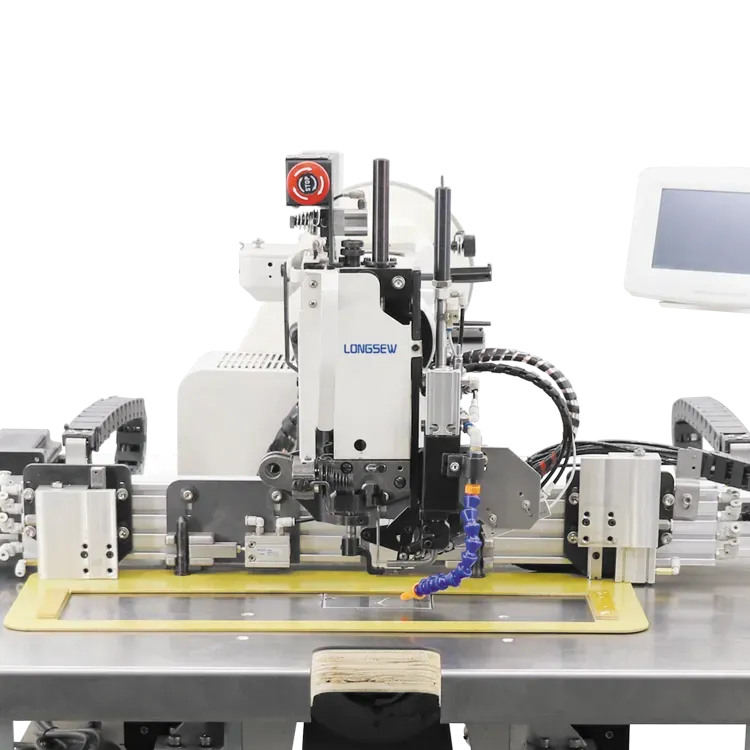

bag closing machine

The Evolution and Importance of Bag Closing Machines

In the modern manufacturing and packaging industry, the efficiency and reliability of packaging systems play a crucial role in ensuring product safety and quality. One of the key components in this process is the bag closing machine. These machines have become indispensable in various sectors, including food, agriculture, chemicals, and textiles, facilitating the seamless sealing of bags for storage and transportation.

Bag closing machines have evolved significantly over the years, adapting to the changing demands of the marketplace. Initially, manual methods for sealing bags involved labor-intensive processes that often led to inconsistencies and inefficiencies. With the advancement of technology, manufacturers began to develop automated bag closing systems, which not only improved sealing speed but also ensured higher quality and precision.

Today’s bag closing machines come in various forms, including sewing, heat sealing, and ultrasonic sealing technologies. For instance, sewing machines use heavy-duty threads to stitch bags closed, making them ideal for products that need extra security. This method is particularly popular in the agricultural sector for grain and feed packaging. On the other hand, heat sealing machines melt the edges of plastic bags to create airtight seals, which are crucial in the food industry to maintain freshness and extend shelf life.

bag closing machine

The selection of a bag closing machine often depends on the type of material being sealed, the nature of the product inside, and the desired output speed

. This flexibility allows manufacturers to optimize their packaging processes based on specific product requirements. For example, in the food industry, where hygiene is paramount, bag closing machines equipped with advanced features like stainless steel construction and easy cleaning mechanisms are essential.Moreover, modern bag closing machines are increasingly being integrated with smart technology. Features such as sensors, programmable logic controllers (PLCs), and automated operation capabilities are making these machines more user-friendly and efficient. With real-time monitoring systems, manufacturers can track the performance of their bag closing operations, leading to reduced downtime and improved productivity.

The importance of bag closing machines goes beyond operational efficiency; they are also crucial for maintaining product integrity. A poorly sealed bag can compromise the product’s quality, leading to waste and potential financial loss. In industries such as pharmaceuticals, where product safety is critical, effective sealing can prevent contamination and ensure compliance with regulatory standards.

In conclusion, bag closing machines are vital components of the packaging process that have evolved to meet modern demands. Their ability to provide secure, efficient, and reliable sealing is essential for various industries, from food to pharmaceuticals. As technology continues to advance, we can expect further innovations in bag closing systems, leading to even greater efficiencies and improved quality in packaging solutions. As businesses strive to enhance their operational capabilities, investing in state-of-the-art bag closing machines will undoubtedly yield significant returns in terms of productivity and product safety.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025