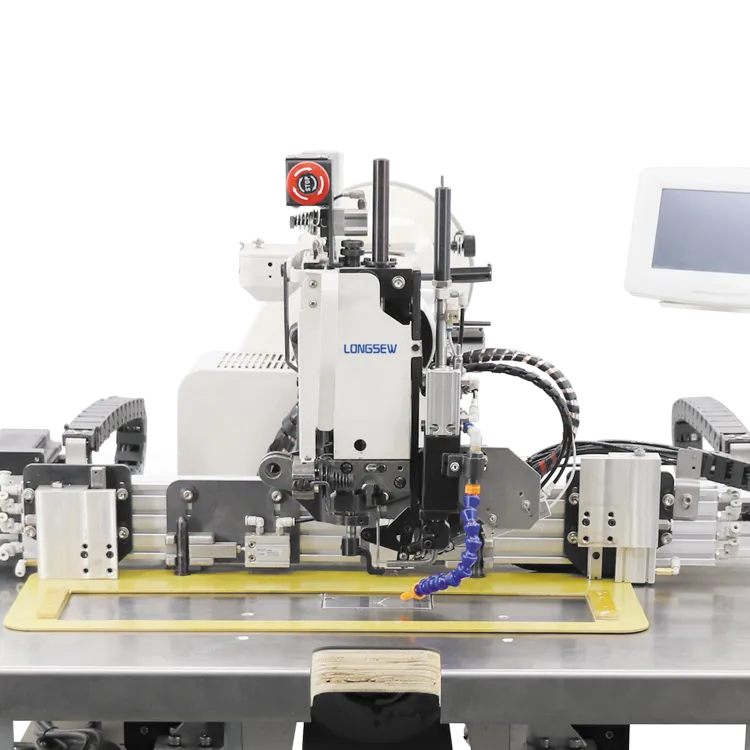

baffle sewing machine

The Art of Baffle Sewing Machines Revolutionizing the Textile Industry

In the ever-evolving world of textile manufacturing, the baffle sewing machine stands out as a revolutionary tool designed to enhance efficiency and precision in the production of various fabric-based products. These machines are crafted to cater to specific needs in the sewing industry, where accuracy and speed are paramount. This article explores the functionality, applications, and advantages of baffle sewing machines, highlighting their significance in modern textile manufacturing.

Understanding Baffle Sewing Machines

Baffle sewing machines are specialized sewing devices that are engineered to create baffles in soft goods such as quilts, comforters, and jackets. A baffle refers to a partition or divider within a fabric item that holds insulation materials in place, ensuring an even distribution of stuffing, which enhances the product’s warmth and comfort. By securely attaching the fabric layers and maintaining the integrity of the insulation, baffle sewing machines play a crucial role in the manufacturing of outdoor gear and bedding products.

These machines feature advanced sewing technology that allows for multiple layers of fabric to be sewn simultaneously. The automation of the sewing process not only improves efficiency but also minimizes the risk of human error, resulting in higher quality outputs. Baffle sewing machines can be programmed to execute specific patterns or designs, facilitating the production of customized goods tailored to market demands.

Applications in the Textile Industry

The primary applications of baffle sewing machines can be found in various sectors of the textile industry. These machines are essential in the production of

1. Bedding Products Quilts and comforters benefit significantly from baffle design as it prevents the filling from shifting, ensuring a comfortable and warm experience for users. Manufacturers can produce high-quality bedding items that are both aesthetically pleasing and functionally effective.

2. Outdoor Apparel Jackets and vests that require insulation can be manufactured using baffle sewing machines to ensure even distribution of insulation materials such as down or synthetic fibers. This is crucial for performance wear, where warmth and weight are key considerations.

baffle sewing machine

4. Specialty Applications Some industries, such as medical or automotive sectors, require unique fabric constructions that can benefit from baffle designs. Baffle sewing machines can be adapted for such niche requirements, showcasing their versatility.

Advantages of Using Baffle Sewing Machines

The implementation of baffle sewing machines brings several advantages to manufacturers in the textile industry

- Increased Efficiency Baffle sewing machines optimize the sewing process, substantially reducing production time. This is especially important for bulk orders and large-scale manufacturing.

- Enhanced Quality Control The precision of baffle sewing machines ensures uniform stitching and consistent quality in the final product. This reliability is crucial for maintaining brand reputation and customer satisfaction.

- Cost-Effective Production By automating the sewing process, manufacturers can save on labor costs while increasing output, thereby improving overall profitability.

- Flexibility and Customization Modern baffle sewing machines are equipped with programmable features that allow manufacturers to create customized designs quickly. This adaptability is an essential asset in an industry where consumer preferences constantly change.

Conclusion

The advent of baffle sewing machines has undoubtedly transformed the landscape of textile manufacturing. By enhancing efficiency, improving product quality, and allowing for greater customization, these machines have become indispensable tools for manufacturers seeking to maintain competitiveness in an ever-changing market. As technology continues to advance, it is likely that baffle sewing machines will evolve further, integrating innovative features that enhance their capabilities. For those operating within the textile industry, investing in baffle sewing technology represents not only a practical choice but also a strategic move towards future growth and sustainability. Ultimately, the baffle sewing machine exemplifies the intersection of craftsmanship and technology, ensuring that quality textiles remain at the forefront of consumer needs.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025