Enhancing Efficiency with Back Closer Machines for Optimal Results

The Back Closer Machine Revolutionizing Industry

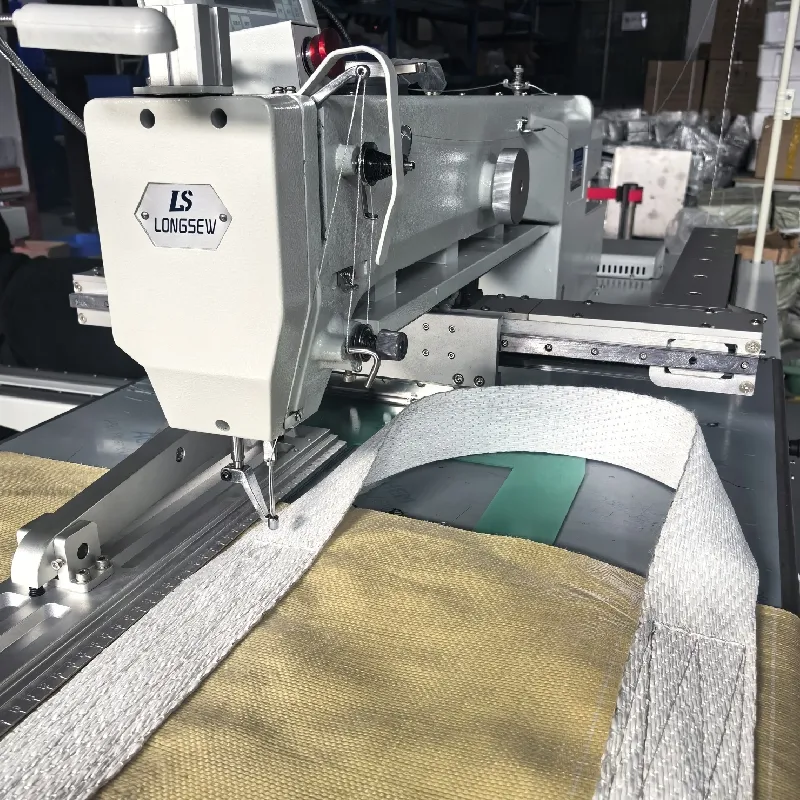

In the ever-evolving landscape of industrial technology, the back closer machine stands out as a pivotal innovation that is transforming manufacturing processes across various sectors. This advanced machinery is specifically designed to enhance efficiency, precision, and safety while streamlining operations. With its ability to automate complex tasks, the back closer machine is becoming an indispensable tool in modern manufacturing environments.

At its core, the back closer machine is engineered to improve the productivity of assembly lines. It specializes in operations that involve the closing of components or products, an essential step in the manufacturing process. Traditional methods often require significant manual labor, which can lead to inconsistencies and errors. By integrating the back closer machine into production lines, companies can achieve higher levels of consistency and accuracy, substantially reducing the error margin.

One of the key features of the back closer machine is its versatility. It can accommodate a wide range of materials, including metals, plastics, and composites, making it suitable for various industries, from automotive to consumer goods. This adaptability allows manufacturers to utilize a single piece of equipment for multiple applications, thereby minimizing investment costs and maximizing space on the factory floor.

Moreover, the back closer machine is equipped with advanced control systems that facilitate real-time monitoring and adjustments

. Operators can easily modify settings to accommodate different products, ensuring that the machine operates optimally according to the required specifications. This level of control not only enhances product quality but also contributes to overall efficiency, as machines can quickly switch between tasks without extensive downtime.back closer machine

In addition to improving efficiency and quality, the back closer machine significantly enhances worker safety. Many manufacturing tasks involve repetitive motions or strenuous lifting, which can lead to workplace injuries over time. By automating these processes, the back closer machine reduces the physical strain on workers, allowing them to focus on more complex and skilled tasks that require human intervention. This shift not only improves the overall work environment but also boosts employee morale.

The environmental impact of manufacturing is another critical consideration in today's industrial practices. The back closer machine incorporates energy-efficient technologies that minimize energy consumption during operation. This not only reduces operational costs for businesses but also aligns with global efforts to promote sustainability and lower carbon footprints within the manufacturing sector.

As industries continue to embrace automation and smart manufacturing, the back closer machine is at the forefront of this transformation. Its ability to enhance productivity, reduce errors, improve worker safety, and promote sustainability positions it as a valuable asset in the contemporary industrial landscape.

In conclusion, the back closer machine represents a significant leap forward in manufacturing technology. By integrating this advanced machinery into production lines, companies can achieve remarkable improvements in efficiency and quality, while ensuring a safer and more sustainable workplace. As we look to the future, the role of such innovative machines will undoubtedly continue to grow, driving both productivity and sustainability in the manufacturing sector.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025