automotive sewing

The Role of Automotive Sewing in the Automotive Industry

Automotive sewing is a specialized field within the automotive industry that focuses on the design, manufacturing, and assembly of textile components used in vehicles. From the seats and headliners to the carpets and door panels, sewing plays a crucial role in determining the aesthetics, comfort, and functionality of a vehicle's interior. As automotive technology advances, so does the necessity for innovative sewing techniques and high-quality materials that can meet modern demands for performance and sustainability.

The first aspect to consider in automotive sewing is the variety of materials involved. Upholstery fabrics, leather, and synthetic textiles are commonly used, each selected for specific properties such as durability, comfort, and aesthetic appeal. For instance, luxury vehicles often utilize high-quality leather that requires precise sewing techniques to ensure flawless seams and an upscale appearance. On the other hand, performance-oriented vehicles may use durable synthetic fabrics designed to withstand extreme conditions while providing comfort.

The sewing process in automotive manufacturing is essential not just for the functionality of the vehicle, but also for its overall design and user experience. A well-executed sewing job can enhance the visual appeal of the interior by creating intricate patterns or using contrasting stitching that adds depth and interest. This attention to detail is particularly important in the competitive automotive market, where consumers are increasingly discerning about the quality and craftsmanship of their vehicles.

automotive sewing

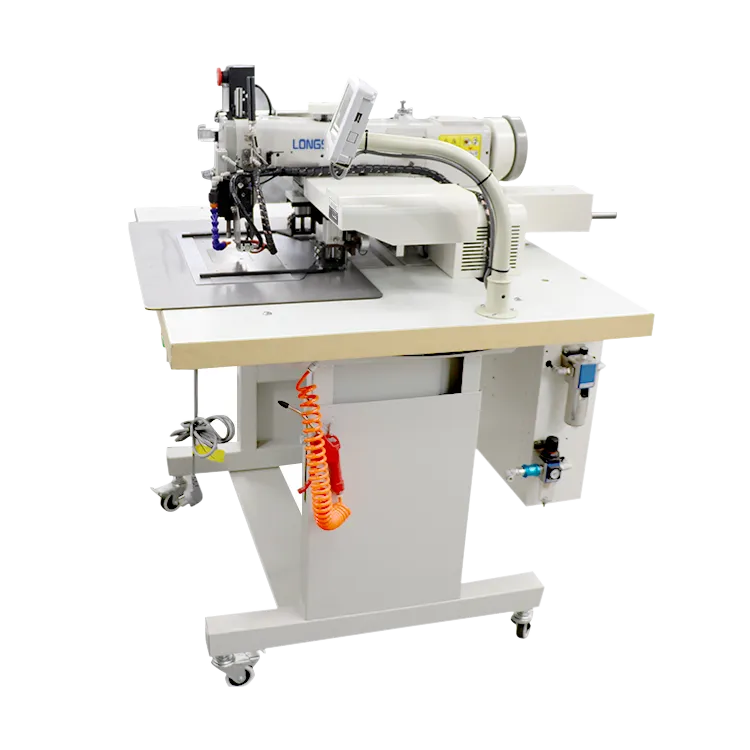

In recent years, advancements in technology have significantly impacted automotive sewing

. Computer-aided design (CAD) and computer-aided manufacturing (CAM) systems have revolutionized the way sewing patterns are created and parts are assembled. These technologies allow for precise measurements and intricate designs that were once difficult or impossible to achieve by hand. Additionally, automated sewing machines equipped with sophisticated software can produce high volumes of components quickly and consistently, improving efficiency and reducing labor costs in the manufacturing process.Sustainability is another crucial consideration in the realm of automotive sewing. As the automotive industry moves toward more eco-friendly practices, manufacturers are increasingly looking for fabrics that are both sustainable and suitable for automotive applications. This includes utilizing recycled materials or bio-based textiles that reduce environmental impact without compromising quality or performance. Moreover, efficient cutting and sewing techniques that minimize waste during the production process contribute to a more sustainable manufacturing approach.

The safety aspect of automotive sewing should not be overlooked. In addition to aesthetic and functional requirements, interior components need to meet strict safety standards. For example, the stitching used in airbags and seatbelts must be resilient and reliable, ensuring that these critical safety features function correctly in the event of an accident. Engineers and designers work closely with sewing specialists to ensure that all materials and sewing techniques adhere to these safety regulations.

In conclusion, automotive sewing is a vital component of the automotive industry that encompasses a broad range of materials, technologies, and artistic elements. As vehicles become more advanced, the demands on sewing techniques and materials will continue to evolve. The integration of technology, sustainability, and safety will shape the future of automotive sewing, prompting manufacturers to innovate and adapt to meet the ever-changing needs of consumers. Through skilled craftsmanship and a commitment to quality, automotive sewing remains an essential part of creating vehicles that are not just modes of transportation but also reflections of style and personal expression.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025