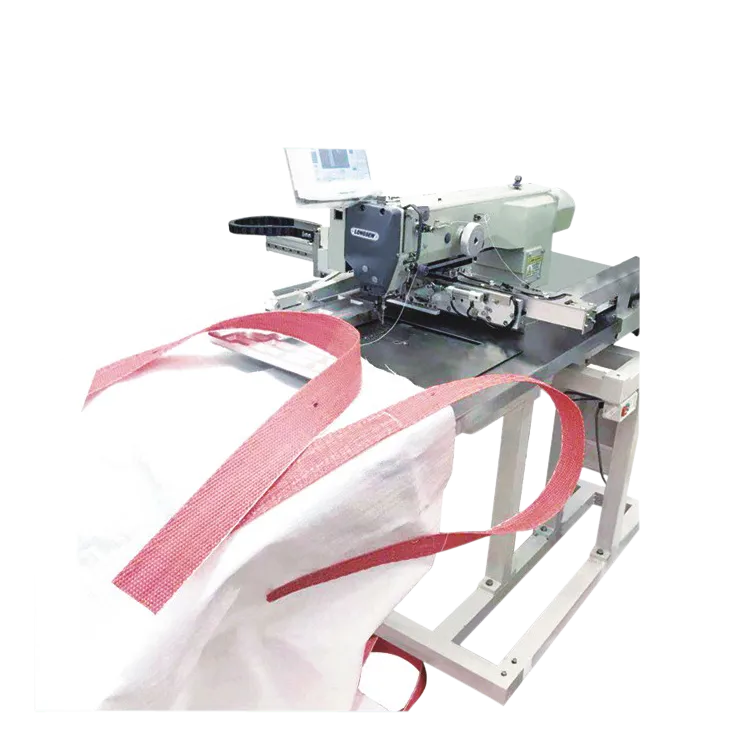

automation sewing machine

The Rise of Automation in Sewing Machines Transforming the Textile Industry

In recent years, the textile industry has witnessed a remarkable transformation driven by technological advancements, particularly in automation. At the forefront of this revolution are automated sewing machines, which have become essential tools for manufacturers seeking to enhance productivity, improve consistency, and reduce labor costs. This article explores the importance of automation in sewing machines and its profound impact on the textile industry.

Traditionally, sewing was a labor-intensive process that required skilled workers to operate sewing machines manually. The advent of automated sewing machines has significantly changed this landscape. These machines are designed to perform a variety of stitching tasks with precision and speed, allowing for higher output levels and reducing the time required to complete garment production.

One of the primary advantages of automated sewing machines is their ability to improve efficiency. By integrating advanced technology such as computer-aided design (CAD) and robotic arms, these machines can operate at a much faster pace than human workers. They can execute complex sewing patterns, handle multiple layers of fabric, and maintain consistent stitching quality throughout the production process. This efficiency not only increases the quantity of goods produced but also allows manufacturers to meet tight deadlines in an increasingly competitive market.

Furthermore, automated sewing machines contribute significantly to reducing production costs. With the ability to operate with minimal human intervention, companies can decrease labor expenses while reallocating their workforce to more strategic roles that require creative input and decision-making. This shift not only helps in cost management but also enhances job satisfaction among employees, as they can focus on more engaging aspects of the production process rather than repetitive tasks.

automation sewing machine

Quality control is another area where automation shines. Automated sewing machines are equipped with sensors and cameras that monitor the stitching process in real-time, ensuring that any defects are detected and corrected immediately. This capability results in a higher overall quality of the finished product, reducing the rate of returns and increasing customer satisfaction. The uniformity in stitching and fabric handling achieved through automation also helps in establishing brand reliability, as consumers increasingly demand high-quality products.

Moreover, the ongoing advancements in artificial intelligence (AI) and machine learning are further refining the capabilities of automated sewing machines. These technologies enable machines to learn from previous tasks, adapt to new designs, and optimize their performance based on user input and feedback. This evolutionary leap not only streamlines production but also makes it easier for manufacturers to experiment with innovative designs and fabrics without significant delays in their processes.

Despite the advantages, the rise of automation in sewing machines raises concerns about the future of skilled labor in the textile industry. While automation undoubtedly enhances efficiency and productivity, it also poses challenges for traditional seamstresses and tailors. The industry must strike a balance by investing in upskilling programs that prepare the workforce for a more automated environment. By embracing technology while also valuing human expertise, the textile industry can create a more sustainable future.

In conclusion, the transformation brought about by automated sewing machines is reshaping the textile industry for the better. With their ability to enhance efficiency, reduce costs, and improve quality control, these machines are indispensable in today’s fast-paced market. As technology continues to evolve, the integration of automation in sewing processes will likely deepen, paving the way for innovations that further redefine garment production. By embracing this change, manufacturers can not only keep pace with industry demands but also foster an environment where both technology and human creativity coexist harmoniously.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025